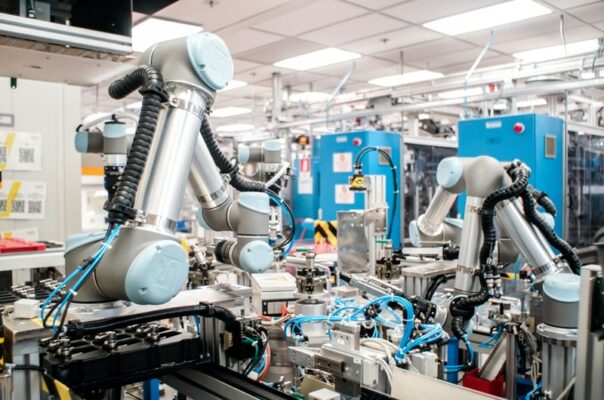

Cobots, or collaborative robots, are designed to work hand-in-hand with humans, they’re making workplaces safer and more efficient across the globe. Whether you’re in manufacturing, healthcare, or even the food industry, there’s a cobot solution that could transform your operations. With their ability to learn and adapt, cobots are not just tools; they’re your future co-workers, ready to tackle a wide range of tasks.

Let’s dive into the proven use cases of cobots and how they can benefit your business today.

What are Cobots?

Cobots are robots that work with you, right where you are. They’re smart enough to avoid getting in your way or causing accidents, thanks to their built-in sensors. You can use them for all sorts of tasks, like putting things together, packing, checking quality, or even in surgeries. They’re super easy to set up to do what you need, making your job safer and faster. Cobots are like helpful teammates, ready to pitch in wherever they’re needed in your workspace.

Why Use Cobots?

1. Boost Efficiency:

Cobots handle repetitive tasks quickly and accurately, freeing up time for workers to focus on complex jobs, making work smoother and more productive.

2. Cut Labor Costs:

Cobots work round the clock without breaks or vacations, saving money over time. They’re also affordable to buy and maintain compared to traditional robots.

3. User-Friendly and Flexible:

Cobots are easy to program and adapt to changing needs. They’re safe to work alongside humans, with safety features to prevent accidents.

4. Enhance Quality:

Cobots use advanced tech to perform tasks with precision, resulting in higher quality products and services.

Industries:

Cobots are being used in a variety of industries to improve efficiency, productivity, and quality. Some of the most common industries include:

1. Manufacturing:

Cobots help with tasks like building, packing, and inspection. They work with people, making work faster and more accurate.

2. Healthcare:

In healthcare, cobots help with things like moving patients and aiding in surgeries. They make things easier for healthcare workers and improve patient care.

3. Logistics and Warehousing:

Cobots help in storage and moving things around. They work non-stop, saving money and getting more done.

4. Food and Beverage:

In food and drinks, cobots help with packing and checking products. They can work in tough places and handle delicate items, improving work and quality.

5. Agriculture:

Cobots help with farming tasks like planting and harvesting. They can work in tricky environments and save time and money for farmers.

These are just some of the industries where cobots are used. As technology keeps getting better, cobots will become even more important in different jobs.

Cobot Applications:

Cobots have a wide range of applications and are being used in various industries to improve efficiency, productivity, and quality. Here are the top 7 applications for cobots:

1. Assembly:

Cobots help put things together in industries like electronics, cars, and airplanes. They can do jobs like screwing, gluing, and checking things with speed and no mistakes.

2. Material Handling:

Cobots move things around, like picking up items, stacking them, and moving materials. They work in tough places and don’t need breaks, saving money and getting more done.

3. Quality Control and Inspection:

Cobots help check if things are good quality. They look at products, measure them, and test them. They’re fast and make fewer mistakes, so things are better.

4. Packaging:

In packing, cobots help put things in bags, boxes, and labels on them. They can work in hard places and with delicate stuff, making work quicker and reducing waste.

5. Painting & Finishing:

Cobots help with painting and finishing tasks like spraying paint, adding coatings, and dispensing materials. They do these tasks very carefully, reducing mistakes and improving quality.

6. Welding & Cutting:

In welding and cutting, cobots do jobs like arc welding and laser cutting. They do it quickly and accurately, reducing mistakes and making things better.

7. Healthcare:

Cobots help move patients, assist in surgeries, and rehabilitation. They make things easier for healthcare workers and improve patient care.

Conclusion:

Cobots are your ultimate work partners, designed to make your job easier and more efficient. They handle the monotonous tasks, allowing you to focus on complex challenges. Easy to program and safe to work alongside, they fit seamlessly into various industries, from manufacturing and healthcare to logistics and agriculture. With cobots, you can boost productivity, save on labor costs, and improve the quality of your work without compromising safety.

Do you want to compare different Cobots?

Are you looking for a System Integrator?