Today, in our world full of technology, mobile robots are changing how industries work, making businesses better and more productive. The fast growth of the global mobile robots market shows that we’re starting something new.

When COVID-19 happened, staying safe and keeping our distance became really important. That’s when mobile robots came to the rescue. They can do things on their own, which means fewer people around. These robots are important for making sure workplaces are safe. Their ability to work independently and connect with things shows how they can transform how we keep our workplaces secure in this new era.

1. Market Insights to Global Growth

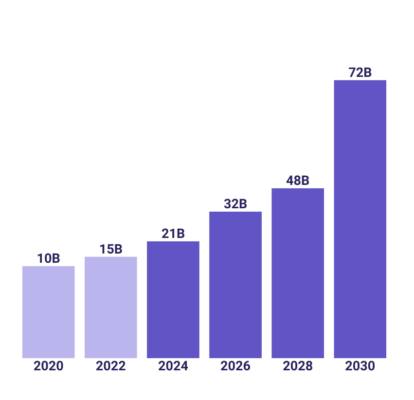

The numbers tell a big story. In 2020, the global market for mobile robots was worth a huge USD 10.7 billion, and they sold an impressive 21 million units. Get ready for what’s coming because it’s predicted that by 2030, the market will be worth a staggering USD 72.5 billion. That’s a fantastic growth rate of 21% every year (Statzon, 2023). These numbers show that mobile robots are making a really big impact and changing how industries work in the future.

2. Industrial Mobile Robots:

Mobile robots with robotic arms are changing how warehouses and logistics work. They move around, pick up, and deliver things. This is a move from robots that stay in one place to ones that can go around.

To show how these robots can work in many different places and industries, let’s look at a few:

a. Manufacturing Industry:

Mobile robots are changing how things are made. They help with moving materials and putting things together in factories. These robots are good at doing the same things over and over, which helps factories work better and faster.

b. Logistics & Warehousing:

Mobile robots are really important in places where they store and send things. They help with keeping track of what’s there, getting orders ready, and organizing the warehouse. They move around quickly and make sure everything is in the right place, which makes the whole process work well and keeps customers happy.

c. Healthcare Sector:

Hospitals and clinics use mobile robots to do helpful jobs like bringing medicine, moving equipment, and keeping patients safe. These robots save time, make fewer mistakes, and make sure doctors and nurses get what they need on time.

d. Agriculture & Mining:

In farming, mobile robots help with taking care of crops and checking the soil and plants. They make it easier for farmers to make decisions. In mining, these robots go into dangerous places to find and dig up important stuff. This makes mining safer and more efficient.

e. Retail & Customer Service:

Mobile robots are changing how stores work. They help keep track of what’s in the store, put things on the shelves, and even help customers. This makes shopping easier and stores run better.

f. E-Commerce:

Online shopping is growing a lot, and mobile robots are a big part of that. They help make sure things run smoothly and with high accuracy. In places like China, they were a big part of how people shopped in 2020. In India, they’re expected to help reach a big sales number by 2026 (Mordor Intelligence, 2023).

g. Seaports:

Think about a world where seaports work really well, making ships come and go faster. Mobile robots are making this happen by changing how seaports and containers move. They make things work better, need less human work, and make everything faster at the ports.

3. Global Giants and Market Pioneers: Unveiling the Champions

The mobile robots market is always changing. Competition, new ideas, and smart plans drive it. Big companies like Teradyne Inc, Fetch Robotics, NextShift Robotics, Aethon Inc, and KION Group AG spend a lot on research to make new and better things for the industry.

Other important companies like ABB, KUKA, Northrop Grumman, iRobot, Lockheed Martin, Honda Motor, Kongsberg Maritime, Samsung Electronics, Amazon Robotics, and Softbank Robotics also do a lot to help. They know a lot and keep making mobile robots better.

Conclusion:

Mobile robots are changing industries worldwide, making them work better and faster. They help in manufacturing, healthcare, logistics, and retail. What’s driving this change is automation, more online shopping, better technology, and help from the government. Businesses need to accept this change to do well in the future. It helps them work better, adjust to new needs, and make the most of opportunities for growth.

To learn more about Mobile Robots.