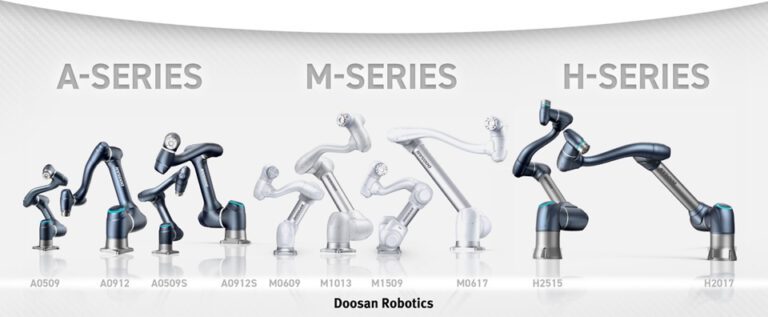

DOOSAN A0912 Pricing & Product Details

Ranked Nr. 227 of 207 Cobots

A0912 Pricing

Choose your model

A0912 Overview

What is A0912?

The Doosan A0912 is a collaborative robot designed for industrial automation, known for its impressive payload capacity and versatile applications. It supports payloads ranging from 5 to 9 kg, making it suitable for handling heavy and bulky items, such as in material handling, packaging, and palletizing operations. This capability enhances efficiency in production lines by automating tasks that involve substantial weights.

Advanced safety features are a key aspect of the A0912. It adheres to stringent safety standards certified by TÜV SÜD, ensuring safe operation alongside human workers in various industrial environments. The robot's design includes safety algorithms that prevent accidents, contributing to a safer work environment.

The A0912 integrates easily with existing production systems due to its compatibility with Doosan Robot Language and third-party software. Its flexibility allows it to operate in diverse conditions, including extreme temperatures, making it suitable for challenging environments where other robots might struggle.

What applications is A0912 product best for?

- Material Handling: The Doosan A0912 is well-suited for tasks such as moving and sorting heavy objects on production lines, enhancing efficiency in material handling operations.

- Packaging: Its robust payload capacity and speed make it ideal for automating packaging processes, including filling, sealing, and labeling of products.

- Palletizing: The robot’s versatility and strength enable it to handle palletizing tasks, arranging goods onto pallets for storage or shipping with precision.

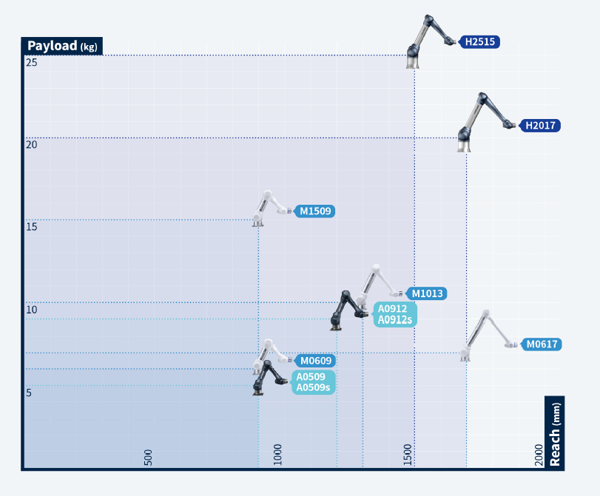

What are the specifications of A0912?

| Payload | 9 kg |

| Reach | 1200 mm |

A0912 FAQ

How do Doosan's robots perform differently?

The strength of a collaborative robot is that it can work with humans. Doosan’s robots can carry out not only simple auxiliary tasks but also collaborative duties with people. A robot that collaborates with people requires a very high level of robotic functionality. Doosan’s robots can exactly simulate the complex action patterns of workers. Doosan’s advanced robotic technologies, such as precise force control and adaptive control, make this possible. Moreover, Doosan has built a robust platform. We created our own robot language to run on the stable platform. We then developed a top-level control algorithm that maximizes robot functionality and allows it to be applied in various fields for the best performance.

Are Doosan's robots easy to use?

The excellent performance and functionality of Doosan robots allow even novices to use them easily. We studied the needs of users by visiting more than 200 sites and analyzing the work process of workers on even non-automated sites from the early stage of robot system development. As a result, Doosan introduced the intuitive and easy-to-use robot solution with maximized UX(User Experience). The outstanding user-friendliness and sophisticated product design of Doosan's robots was recognized by winning the prestigious Red Dot Design Award for two consecutive years - in the "Interface & User Experience" category & "Product Design" category.

Are Doosan Robotics' collaborative robots really safe?

Doosan's robots have a built-in precision torque sensor in each of six axes for excellent collision detection. The sensors protect workers by detecting even minor collisions. Moreover, the unique functions of the Doosan robot, such as Virtual Fence and Safety Zone, can set additional cooperative zones to improve safety. Easy interface with other safety systems, such as laser scanners, also ensures safety. Doosan robots work best if the environment around the robot and the safety of peripheral devices are secured.