Robotnik RB-ROBOUT Pricing & Product Details

Ranked Nr. 14 of 183 Mobile Robots

RB-ROBOUT Pricing

Choose your model

RB-ROBOUT Overview

What is RB-ROBOUT?

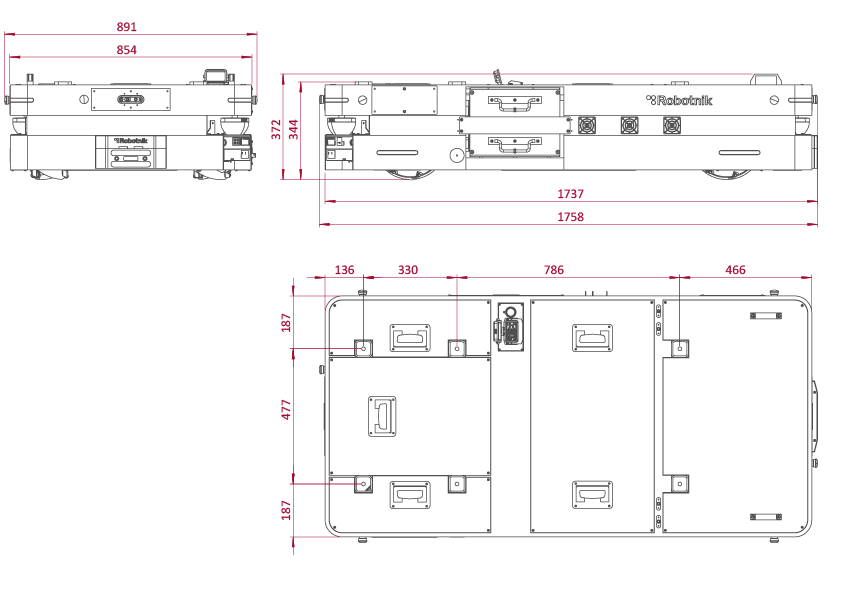

The Robotnik RB-ROBOUT is an advanced autonomous mobile robot (AMR) engineered for heavy-load transport in indoor environments, specifically suited for industrial and logistics settings. With a robust payload capacity of up to 1,000 kg, it can move materials and goods efficiently within factories and warehouses. Its low-profile, steel-bodied design allows it to navigate under and lift trolleys or carry large loads directly on its platform, optimizing space use and enhancing transport flexibility in confined environments.

Equipped with omnidirectional kinematics and four high-powered drive wheels, the RB-ROBOUT achieves smooth, multidirectional movement, allowing it to navigate tight spaces and optimize routes. Its safety features, including dual 2D safety scanners and front and rear RGBD cameras, enable it to operate alongside human workers by detecting obstacles and autonomously rerouting as needed. This AMR supports various localization systems like SLAM for dynamic mapping and magnetic guidance for applications requiring high-precision positioning.

The RB-ROBOUT’s modular architecture, based on the ROS framework, allows for easy integration with additional components, such as conveyor belts, roller paths, and load elevators. Its autonomy of up to 10 hours, combined with optional AI and vision packages, makes it highly adaptable for diverse industrial applications, including loading/unloading, material transport, and specialized logistics tasks. This flexibility in configuration and customization makes the RB-ROBOUT an effective solution for automating repetitive heavy-load transport tasks in complex, high-demand environments.

What applications is RB-ROBOUT product best for?

- Industrial Material Transport: The RB-ROBOUT is designed for heavy-duty material transport within industrial facilities, allowing efficient movement of up to 1,000 kg loads across production areas. Its omnidirectional mobility and robust payload make it ideal for transporting raw materials or components in manufacturing settings.

- Warehouse Loading and Unloading: This AMR excels in warehouse environments for tasks like loading and unloading heavy pallets and material trolleys. With options like a roller conveyor and load elevators, it streamlines the process of handling bulky items, reducing manual labor in high-volume storage facilities.

- Intralogistics for Assembly Lines: The RB-ROBOUT is highly suited for intralogistics applications, specifically for moving parts and assemblies along production lines in automotive or electronics manufacturing. Its precise navigation and safety features allow it to operate alongside human workers, enhancing workflow continuity on complex assembly floors.