DS AUTOMOTION Flexihauler Pricing & Product Details

Ranked Nr. 174 of 183 Mobile Robots

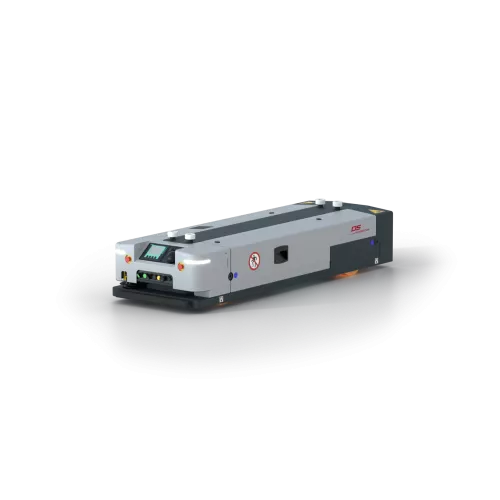

Flexihauler Overview

What is Flexihauler?

DK Automation's Flexihauler is a cost-effective solution designed for in-plant logistics. With its simple and robust design, Flexihauler stands out as a reliable option for efficient material transportation. It operates as a track-guided vehicle, making integration into existing systems seamless without the need for complex system control.

One of the standout features of the Flexihauler is its simplicity. To set it up in your plant, only one track needs to be glued, and the vehicle is ready to move. There's no requirement for intricate plant control systems. The Flexihauler utilizes extendable pins to dock onto mobile transport racks, allowing it to efficiently pull and transport them along the track. This streamlined approach enables quick and easy commissioning.

The Flexihauler's track-guided operation further enhances its ease of use and integration. It seamlessly fits into existing systems without the need for complex system control, simplifying the overall automation process. The standardized PLC control system is low-maintenance and offers the flexibility to adapt to individual interfaces, ensuring a seamless integration experience.

Robustness is another key feature of the Flexihauler. With its simple construction and robust technology, it is built to withstand the demands of industrial environments, even under tough conditions. This durability ensures a long service life, reducing downtime and maintenance costs.

The Flexihauler finds application in various scenarios, particularly in concatenation processes. It allows for the easy connection of individual stations within an operation, enabling seamless and automated material flow between different areas. This capability improves efficiency, reduces manual handling, and enhances overall productivity.

In terms of specifications, the Flexihauler offers a maximum payload of 1,000 kilograms (2,200 pounds) and a maximum speed of 1.2 meters per second (4 feet per second). These specifications make it suitable for handling a wide range of loads and ensuring swift and reliable transportation within the plant environment.