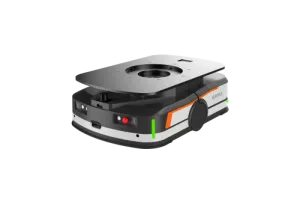

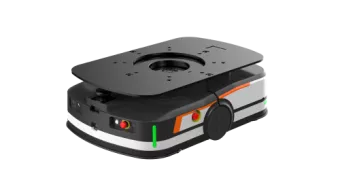

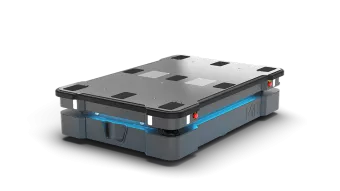

Geek+ P500 Specifications

Ranked Nr. 65 of 183 Mobile Robots

Geek+ P500 is an automated guided vehicle (AGV) designed for material handling and warehouse automation. It has a maximum lifting load capacity of 600 kg and can handle shelf sizes up to 880 x 880 mm. The vehicle achieves a maximum no-load speed of 2 m/s and a full-load speed of 1.6 m/s, with a maximum lifting height of 60 mm.

The P500 enhances operational efficiency by improving productivity by up to three times compared to manual labor, with an accuracy rate of 99.99%. It significantly reduces labor needs by 50% to 70% and lowers labor intensity, making it suitable for high-throughput environments where quick and accurate material handling is essential.

Its deployment is rapid, with a full system setup possible within three months, and as fast as two weeks in some cases. The P500 also features high flexibility, with the ability to integrate additional robots as needed, and incorporates patented safety solutions to ensure secure human-robot interaction, meeting CE standards.

| Dimensions | |

| Payload | 600 kg |

| Product mass | 170 kg |