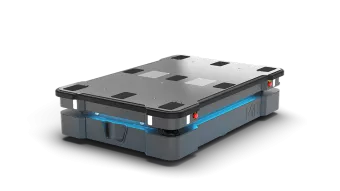

Geek+ P800R Specifications

Ranked Nr. 69 of 183 Mobile Robots

The Geek+ P800R is designed for high-efficiency warehouse operations, providing significant enhancements over manual labor. It delivers up to 3 times the efficiency of human workers and achieves accuracy rates of up to 99.99%, making it ideal for environments requiring precise and consistent handling of goods.

The system boasts a quick return on investment, typically within 3 years, thanks to its ability to reduce labor needs by 50% to 70% and lower labor intensity. This makes it a cost-effective alternative to traditional automation solutions, with fast deployment options that can be completed within 2 to 3 months.

The P800R offers high flexibility, allowing for the easy addition or removal of robots based on changing needs. Its safety features, compliant with CE standards, ensure secure human-robot interaction while maintaining high fault tolerance, contributing to overall operational safety.

| Product mass | 162 kg |

| Dimensions | |

| Payload | 1000 kg |