Kivnon K11 Two-Way Alternatives & Competitors

Ranked Nr. 149 of 183 Mobile Robots

Top 10 K11 Two-Way Alternatives

- Kivnon K10 One-Way

- Kivnon K05 Twister

- Kivnon K03 Twister

- Kivnon K32 Tractor

- Kivnon K41 Omnidirectional

- STÄUBLI PF100

- Kivnon K55A Pallet Stacker

- STÄUBLI PF280

- Synersight CM25

- STÄUBLI PF245

- Neobotix MPO-700

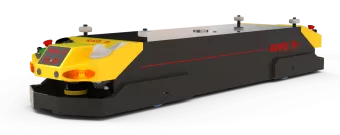

Kivnon K10 One-Way

The Kivnon K10 One-Way is a small and powerful AGV designed specifically for towing trolleys in a single direction. It is an ideal solution for automating the transport of large loads over long distances in one-way processes. With a towing capacity of up to 3,000kg on a wheeled trolley, it can handle heavy loads with ease.

The K10 One-Way features magnetic guidance navigation, ensuring accurate and reliable movement along predefined paths. This allows for precise and efficient transport within its operating environment. It can be seamlessly integrated with fleet management systems, including those based on VDA 5050, enabling centralized control and optimization of multiple AGVs.

One of the standout capabilities of the K10 One-Way is its ability to make high precision stops with full accuracy. This ensures efficient loading and unloading operations, contributing to overall productivity and minimizing errors. Its compact dimensions, with two available versions (K10 and K10P), allow it to operate in tight spaces and navigate through narrow aisles.

The K10 One-Way offers flexibility in terms of battery options, supporting AGM or lithium batteries. These batteries are exchangeable and support online charging through an integrated circuit, ensuring continuous operation without interruptions.

Safety is a top priority for the K10 One-Way, as it is equipped with safety features such as a laser scanner, ultrasound sensor, safety PLC, and Bluespot technology. These measures help detect obstacles, prevent collisions, and ensure the safety of operators and other equipment in the vicinity of the AGV.

Overall, the Kivnon K10 One-Way is a reliable and efficient solution for automating one-way processes in industrial settings. Its robust towing capacity, precise maneuverability, compatibility with fleet management systems, and focus on safety make it an excellent choice for industrial automation applications.

Kivnon K05 Twister

The Kivnon K05 Twister is a small and versatile AGV/AMR (Automated Guided Vehicle/Autonomous Mobile Robot) designed specifically for automating the transport of medium loads in highly specific processes and work environments where space is limited. It stands out with its ability to perform a 360-degree rotational movement on its own axis, allowing for exceptional maneuverability and precise positioning.

With an on-board load capacity of up to 450kg and a towing capacity of up to 1,000kg on a wheeled trolley, the K05 Twister is capable of handling various types of loads. It offers different coupling systems, including a retractable pin, lift table, roller conveyor, and even the option to use it as a workbench. This adaptability makes it a versatile solution for a wide range of industrial automation applications.

The K05 Twister features magnetic guidance navigation, which ensures accurate and reliable movement within its operating environment. It can be easily integrated with fleet management systems, including those based on VDA 5050, allowing for seamless coordination and optimization within larger automation setups.

Precision is a key capability of the K05 Twister, enabling it to make precise stops with full accuracy. This ensures efficient and error-free material handling operations, improving productivity and reducing downtime.

In terms of dimensions, the K05 Twister is compact, measuring 800mm in length, 800mm in width, and 280mm in height. This compact form factor allows it to operate in tight spaces and navigate through narrow aisles with ease.

The K05 Twister is powered by either AGM or lithium batteries, and it supports online charging through an integrated circuit.This enables continuous operation without the need for frequent battery replacements, ensuring uninterrupted productivity.

Safety is a priority for the K05 Twister, as it is equipped with a laser scanner and a safety PLC (Programmable Logic Controller) to detect obstacles, prevent collisions, and ensure the well-being of operators and other equipment in its vicinity.

With its compact size, versatile coupling options, precise maneuverability, and compatibility with fleet management systems, the Kivnon K05 Twister offers a unique solution for industrial automation in confined spaces. Its high load capacity, adaptability, and advanced navigation capabilities make it an ideal choice for various applications in industries such as manufacturing, logistics, and warehousing.

Kivnon K03 Twister

The Kivnon K03 Twister is an advanced AGV/AMR (Automated Guided Vehicle/Autonomous Mobile Robot) model specifically designed for automating the transport of medium loads in highly specific processes and work environments where space is limited. Its standout feature is its ability to perform a 360-degree rotational movement on its own axis, allowing for greater flexibility of movement and minimizing the time required for operations.

With an on-board load capacity of up to 200kg, the K03 Twister is capable of handling various types of loads. It features a rotational lift table that securely lifts and transports tables, trolleys, and KLT's, providing efficient and reliable material handling solutions.

The K03 Twister offers different guidance options, including magnetic guidance or mapping navigation. This allows the robot to navigate and operate accurately within its environment, ensuring precise movement and positioning. Additionally, it can be adapted to connect with fleet management systems, including those based on VDA 5050, enhancing its integration capabilities within larger automation setups.

One of the notable capabilities of the K03 Twister is its high precision in making stops with full accuracy. This ensures precise positioning when loading and unloading materials, contributing to efficient and error-free operations.

In terms of dimensions, the K03 Twister is compact, measuring 700mm in length, 500mm in width, and 280mm in height. This compact form factor enables it to navigate through narrow spaces and operate in environments with limited room for maneuverability.

The K03 Twister is equipped with a lithium battery that supports online charging through an integrated circuit. This allows for continuous operation without the need for frequent battery replacements or downtime.

To ensure safety, the K03 Twister is equipped with a laser scanner, a safety PLC (Programmable Logic Controller), and LED signaling. These safety measures help detect obstacles, prevent collisions, and alert operators to the robot's status and any potential errors.

With its unique features, the Kivnon K03 Twister offers a specialized solution for industrial automation, particularly in environments where space is limited and precise movement is crucial. Its ability to rotate on its own axis, high load capacity, adaptability to different guidance systems, and compatibility with fleet management systems make it a versatile and efficient option for various applications in industries such as manufacturing, logistics, and warehousing.

Kivnon K32 Tractor

The Kivnon K32 Tractor is an AGV/AMR designed for efficient and reliable load transportation in internal logistics processes. With its one-way movement and towing capacity of up to 2,000kg, it's ideal for handling large loads.

The AGV utilizes magnetic guidance navigation for precise maneuvering and can be seamlessly integrated with fleet management systems, including those based on VDA 5050. This allows for optimized coordination and control of the AGV within the overall logistics operations.

With high precision and advanced safety measures, including laser scanners, ultrasound sensors, and a safety PLC, the K32 Tractor ensures accurate stops and secure operations. These features contribute to a safe working environment and help prevent collisions or accidents.

The K32 Tractor comes in two versions: the K32 and K32P, offering flexibility to meet different operational requirements. Its compact dimensions, with a length of 1170mm, width of 480mm, and height of 1040mm, allow for easy maneuverability in tight spaces.

The AGV is powered by either AGM or lithium batteries, offering exchangeable and online charging capabilities through an integrated circuit. This ensures continuous operation without the need for manual battery replacement.

The K32 Tractor's standout features, towing capacity, compatibility with fleet management systems, and advanced safety measures make it a reliable and efficient solution for industrial automation in various sectors.

Kivnon K41 Omnidirectional

The Kivnon K41 Omnidirectional AGV/AMR is a unique solution for automating the transport of medium loads in highly complex processes. Its standout feature is its omnidirectional mobility, which allows it to maneuver in any direction with ease. Unlike other AGVs/AMRs, the K41 can perform maneuvers that were previously impossible, making it highly versatile in tight spaces and intricate work environments.

With a load capacity of up to 800kg, the K41 is capable of handling substantial loads. It offers precise navigation, ensuring accurate stops with full accuracy. The AGV/AMR is equipped with mapping navigation, allowing it to efficiently move throughout the facility. Additionally, it can be adapted to connect with fleet management systems, including those based on VDA 5050, for seamless integration into existing operations.

Safety is a top priority for the K41. It features 360º safety with laser scanners, ensuring obstacle detection and collision avoidance. The AGV/AMR also incorporates a safety PLC and LED signaling to enhance operational safety. On each front side, there is a status, error, and circuit control touch display, providing real-time information about its operation.

Measuring 1620mm in length, 850mm in width, and 285mm in height, the K41 offers a compact and space-efficient design. It operates in a lifting transport type, accommodating different load requirements. With a maximum speed of 1 m/s, it delivers efficient and timely transport. The K41 is powered by a lithium battery, supporting online charging in an integrated circuit for continuous operation.

The K41's versatility extends beyond load transport. It features a coupling system that can adapt to various trolleys, allowing for seamless integration with existing equipment. Moreover, it can serve as a workbench, further enhancing its utility in industrial settings.

With its exceptional maneuverability, high load capacity, and adaptability, the Kivnon K41 Omnidirectional AGV/AMR revolutionizes material transport in complex industrial automation processes.

STÄUBLI PF100

Stäubli's PF100 is part of their premium AGV (Automated Guided Vehicle) platform series, which has been a trusted choice for manufacturing automation over the last two decades. The PF100, designed for high payload applications, stands out with its impressive capability to transport loads of up to 6 tons. What sets it apart is its omni-directional motion, offering superior maneuverability on the factory floor. Additionally, it boasts high positioning precision, with an accuracy of 5 mm, ensuring that it can handle tasks demanding utmost precision.

One of the unique aspects of the PF100 is its adaptability to both indoor and outdoor environments, providing end-to-end solutions for various industries. This flexibility is crucial for applications where the AGV may need to transition between different working conditions. Furthermore, the PF100 features laser navigation technology for precise and reliable movement, ensuring efficiency and safety in its operations.

The PF100 finds applications in diverse industries, from automotive press shops and assembly lines to e-battery manufacturing, heavy metal industries, and even the semiconductor sector with a cleanroom version. Its ability to handle sensitive and high-precision tasks in demanding environments makes it a valuable asset in industrial intralogistics, railway assembly lines, wind power, and the paper industry. The Stäubli PF100 AGV offers a versatile and robust solution for a wide range of automation needs, particularly those requiring agility, precision, and high payload capabilities.

Kivnon K55A Pallet Stacker

The Kivnon K55A Pallet Stacker is an innovative lifting automated guided vehicle (AGV/AMR) designed specifically for the transportation and stacking of palletized loads. Unlike traditional forklifts, this AGV/AMR model is equipped with advanced automation capabilities, allowing it to perform robotic process automation applications and interact seamlessly with other AGVs/AMRs, machines, systems, and people.

One of the standout features of the K55A Pallet Stacker is its ability to adapt to various pallet storage applications, including open bottom or American pallets. It is a versatile solution for both internal material dispatches and optimizing storage in intralogistics automations. This adaptability ensures enhanced process efficiency in a wide range of industrial environments.

The K55A Pallet Stacker offers precise and accurate movement, thanks to its high precision capabilities. It can make precise stops with full accuracy, ensuring efficient and reliable handling of palletized loads. The AGV/AMR utilizes lineal, two-way movement, enabling seamless navigation through different areas of the facility.

With a load capacity of up to 2,600 lbs (1,180 kg), the K55A Pallet Stacker is capable of handling heavy loads with ease. Its lifting capacity reaches up to 5 feet (1.5 meters), allowing for efficient stacking and storage of palletized goods. The AGV/AMR is designed to optimize productivity and streamline operations in various industries, including automotive and Tier 1 suppliers, manufacturing, and food and beverage.

In terms of connectivity, the K55A Pallet Stacker can be easily adapted to connect with fleet management systems. This enables seamless integration into existing automation setups, allowing for centralized control and coordination of multiple AGVs/AMRs. The compatibility with fleet management systems, including those based on VDA 5050, enhances operational efficiency and enables comprehensive monitoring and management of the AGV/AMR fleet.

The K55A Pallet Stacker is equipped with mapping navigation, which ensures efficient and accurate movement within the facility. It can navigate predefined routes and adapt to changing environments, making it suitable for dynamic and evolving industrial settings. This AGV/AMR is designed to optimize internal logistics and warehousing processes, facilitating smooth material flow and minimizing manual intervention.

In terms of technical specifications, the K55A Pallet Stacker has a length of 1,933 mm, a width of 1,354 mm, and a height of 2,346 mm. It operates as a lifting AGV and achieves a maximum speed of 2.2 mph (3.5 km/h). The AGV/AMR is powered by a lithium battery that supports online charging in an integrated circuit, ensuring continuous operation and minimizing downtime.

Overall, the Kivnon K55A Pallet Stacker stands out as a highly capable and adaptable solution for industrial automation. Its advanced automation capabilities, precise movement, high load and lifting capacities, and compatibility with fleet management systems make it a unique option for optimizing internal logistics, warehousing, and material handling processes.

STÄUBLI PF280

Stäubli's PF280 is part of their premium AGV (Automated Guided Vehicle) platform series, which has been a trusted choice for manufacturing automation over the last two decades. The PF245, designed for high payload applications, stands out with its impressive capability to transport loads of up to 90 tons. What sets it apart is its omni-directional motion, offering superior maneuverability on the factory floor. Additionally, it boasts high positioning precision, with an accuracy of 5 mm, ensuring that it can handle tasks demanding utmost precision.

One of the unique aspects of the PF280 is its adaptability to both indoor and outdoor environments, providing end-to-end solutions for various industries. This flexibility is crucial for applications where the AGV may need to transition between different working conditions. Furthermore, the PF280 features laser navigation technology for precise and reliable movement, ensuring efficiency and safety in its operations.

The PF280 finds applications in diverse industries, from automotive press shops and assembly lines to e-battery manufacturing, heavy metal industries, and even the semiconductor sector with a cleanroom version. Its ability to handle sensitive and high-precision tasks in demanding environments makes it a valuable asset in industrial intralogistics, railway assembly lines, wind power, and the paper industry. The Stäubli PF280 AGV offers a versatile and robust solution for a wide range of automation needs, particularly those requiring agility, precision, and high payload capabilities.

Synersight CM25

Intended for the transport of heavy loads, offering the option of working outdoors and manual handling.

This model allows the dragging transport of heavy loads of 25.000 Kg., in international and external logistics. They are very efficient machines, since they allow large amounts of product to be moved and the load to be hooked or unhooked automatically, thanks to the type of hook they incorporate.

Despite their robustness, they are very safe machines as they are designed with the most modern security technologies on the market.

STÄUBLI PF245

Stäubli's PF245 is part of their premium AGV (Automated Guided Vehicle) platform series, which has been a trusted choice for manufacturing automation over the last two decades. The PF245, designed for high payload applications, stands out with its impressive capability to transport loads of up to 40 tons. What sets it apart is its omni-directional motion, offering superior maneuverability on the factory floor. Additionally, it boasts high positioning precision, with an accuracy of 5 mm, ensuring that it can handle tasks demanding utmost precision.

One of the unique aspects of the PF245 is its adaptability to both indoor and outdoor environments, providing end-to-end solutions for various industries. This flexibility is crucial for applications where the AGV may need to transition between different working conditions. Furthermore, the PF245 features laser navigation technology for precise and reliable movement, ensuring efficiency and safety in its operations.

The PF245 finds applications in diverse industries, from automotive press shops and assembly lines to e-battery manufacturing, heavy metal industries, and even the semiconductor sector with a cleanroom version. Its ability to handle sensitive and high-precision tasks in demanding environments makes it a valuable asset in industrial intralogistics, railway assembly lines, wind power, and the paper industry. The Stäubli PF245 AGV offers a versatile and robust solution for a wide range of automation needs, particularly those requiring agility, precision, and high payload capabilities.