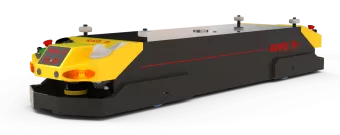

Kivnon K55 Pallet Stacker Specifications

Ranked Nr. 153 of 183 Mobile Robots

The Kivnon K55 Pallet Stacker is an automated guided vehicle (AGV/AMR) designed specifically for the movement and stacking of palletized loads at low heights. It is a versatile mobile robot capable of performing cyclical or conditional circuits and interacting with other AGVs/AMRs, machines, systems, and people.

One of the standout features of the K55 Pallet Stacker is its ability to adapt to various pallet storage applications, including open bottom or Euro-pallets. It is the perfect solution for automating the transport of medium loads at heights, making it ideal for tasks such as reception and dispatch of goods and internal material transport. This stacker optimizes storage space and improves process efficiency in a wide range of industrial applications.

The K55 Pallet Stacker offers precise and accurate movement, thanks to its high precision capabilities. It can make precise stops with full accuracy, ensuring efficient and reliable handling of palletized loads. The AGV/AMR utilizes lineal, two-way movement, enabling seamless navigation through different areas of the facility.

With a load capacity of up to 1,000 kg (2,204 lbs), the K55 Pallet Stacker can handle medium-sized loads with ease. Its lifting capacity reaches up to 1,500 mm, allowing for efficient stacking and storage of palletized goods at low heights. The stacker is designed to optimize productivity and streamline operations in various industries.

In terms of connectivity, the K55 Pallet Stacker can be easily adapted to connect with fleet management systems, including those based on VDA 5050. This enables seamless integration into existing automation setups, allowing for centralized control and coordination of multiple AGVs/AMRs. The compatibility with fleet management systems enhances operational efficiency and enables comprehensive monitoring and management of the AGV/AMR fleet.

The K55 Pallet Stacker operates as a lifting AGV and achieves a maximum speed of 1 m/s (3.6 km/h). It is powered by a lithium battery that supports online charging in an integrated circuit, ensuring continuous operation and minimizing downtime. The stacker incorporates various safety measures, including 360º safety via laser scanners, safety PLC, and LED signaling, ensuring a safe working environment.

The K55 Pallet Stacker features a frontal status, error, and circuit control display, providing real-time information and easy monitoring of its operation. Its dimensions are 1,933 mm in length, 920 mm in width, and 2,346 mm in height. These specifications make it a compact and maneuverable solution for industrial automation.

In summary, the Kivnon K55 Pallet Stacker offers a range of features and capabilities that make it a unique option for industrial automation. Its adaptability to different pallet storage applications, precise movement, high load and lifting capacities, compatibility with fleet management systems, and safety measures contribute to improved efficiency and optimized material handling processes in diverse industries.

| Payload | 1000 kg |

| Speed | 1 m/s |

| Type of Technology |

|

| Application |

|

| Industry |

|