Lowpad Lowpad S Pricing & Product Details

Ranked Nr. 91 of 183 Mobile Robots

Lowpad S Overview

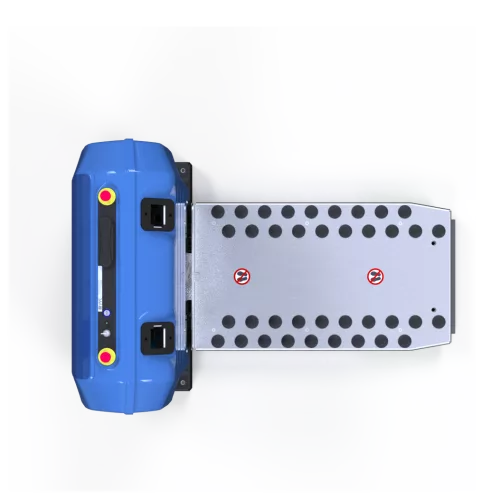

What is Lowpad S?

The Lowpad S is the perfect automation solution for (food) distribution centres and post and parcel companies. Robust and safe AMRs to transport roll cages. Our Lowpads enable you to optimize your performance through increased insights, accuracy and better utilization of scarce human resources.

Looking for ways to automate your transport of roll cages?

The Lowpad S is the ultimate autonomous mobile robot that can handle existing roll cages. Due to its unique characteristics, the Lowpad is versatile and can automate various logistical processes.

Improve your productivity and lower your operational costs in your intralogistics. Through high technology, we offer the best quality solution in collaboration with your wishes.

Loads

The ideal solution for the autonomous movement of roll cages. Due to its great load capacity and specialized mechanical characteristics, the Lowpad S can handle a wide variety of roll cages.

1. Improved efficiency

Able to boost your productivity.

2. Smart integrations

Easy to integrate and able to exchange data with existing systems such as ERP or WMS.

3. Ultra-low

The Lowpad S fits underneath existing roll cages

4. Omnidirectional driving

Small turning radius for small pathways

What applications is Lowpad S product best for?

PERFECT SOLUTION FOR:

ROLL CAGES AND CARTS

Applications:

Inbound

Inbound logistics entails the transportation and storage of incoming goods. By automating this process with the Lowpad, inbound logistics can be managed more efficiently.

Goods to Person

Goods are retrieved from storage and autonomously transported by Lowpads to the operator that executes the picking.

Cross docking

Goods are autonomously transported between the docks by Lowpads. Resulting in a more efficient use of docs, higher accuracy, less manual labor and less drop shipping failures.

A to B transport

The Lowpads are very versatile meaning that they can implemented in numerous types movements. As the Lowpad can drive without any infrastructural changes required, they can automate simple transport jobs where goods have to be transported from point to point.

Dynamic Zone Picking

Operators are allocated to a dynamic zone where they pick all SKUs in their area. Lowpads transport the pick runs and Lowpad Organiser software calculates the most efficient task planning for the operators.

Marshalling

Shipping can be complex, the costs are significant, and there is an ever-present risk of the slightest error because of the labor-intensive process. Our marshalling solution will help you deliver your load carriers, autonomously, to the right dock at the right time, nicely lined up and in the right loading sequence.

What are the specifications of Lowpad S?

| Payload | 450 kg |

| Technology |

|