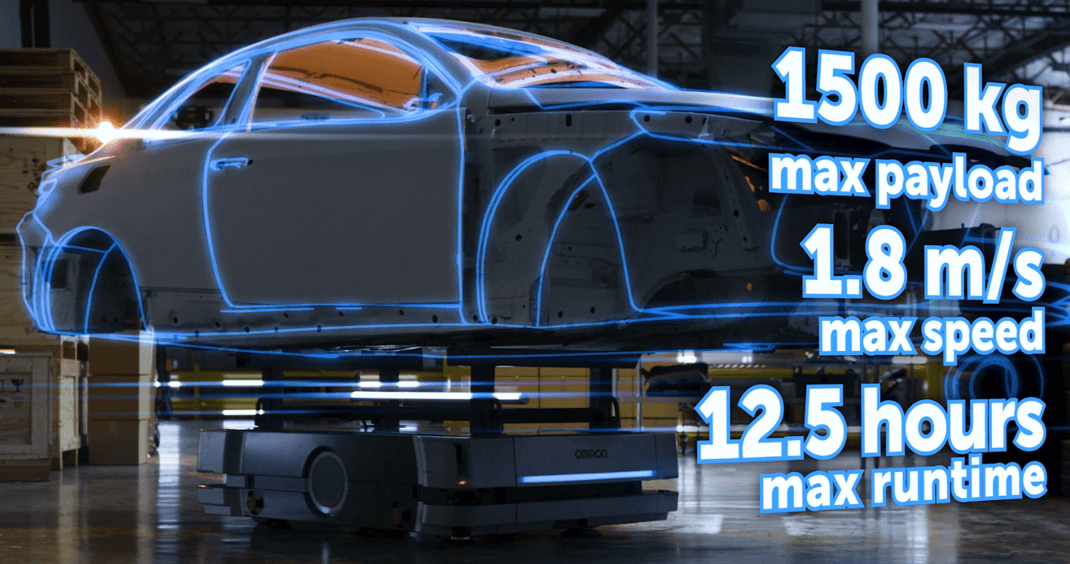

OMRON HD-1500 Specifications

Ranked Nr. 36 of 183 Mobile Robots

The HD-1500 boasts a payload capacity of 1,500 kg and allows customers to lead and transport the heaviest of objects. Designed for industrial manufacturing, reduce the need for forklifts and do more with less equipment.

The HD-1500 is an advanced autonomous mobile robot specifically designed to transport heavy payloads up to 1500 kilograms. The HD-1500 also represents innovations in mobile robotics. Its new architecture features lasers that provide 360-degree safety coverage, as well as an onboard programmable logic controller, or PLC, to easily interface with custom attachments. Heavier payloads, built-in controller, improved sensors, route planning and object avoidance, the OMRON HD-1500 autonomous mobile robot offers the most advanced performance and safety.

Features:

Maximum payload is 1500 kg

The 1,500 Kg payload Omron HD-1500 mobile robot handles the performance of simple transport, delivery, and routing operations so your employees can perform higher-value jobs.

Automate new jobs

The higher payload capacity allows customers to automate new tasks that were not previously possible, such as the transport of pallet-size loads, engine blocks, and other heavy goods and equipment. The HD-1500 can also automate tasks that are traditionally completed with forklifts, reducing the risk of injury.

The most customizable solution for your factory

Omron allows customers more options in terms of customizing a mobile solution, which now includes incorporating the HD-1500, giving customers more choice in developing a customized automated solution.

The HD-1500 can be used to create a solution that best meets the needs of every manufacturer.The HD-1500 also takes advantage of Omron’s ability to customize the fleet with accessories that improve performance, such as HAPS and LiDAR. With the industry-leading Fleet Manager, Omron mobile fleets can be more diverse and still be controlled through the same system, allowing for a completely automated solution. Designed to meet the industry’s latest requirements, our mobile robots interact with people to promote a collaborative, safe working environment.

| Technology |

|

| Payload | 1500 kg |