Robotnik RB-KAIROS Pricing & Product Details

Ranked Nr. 14 of 183 Mobile Robots

RB-KAIROS Pricing

Choose your model

RB-KAIROS Overview

What is RB-KAIROS?

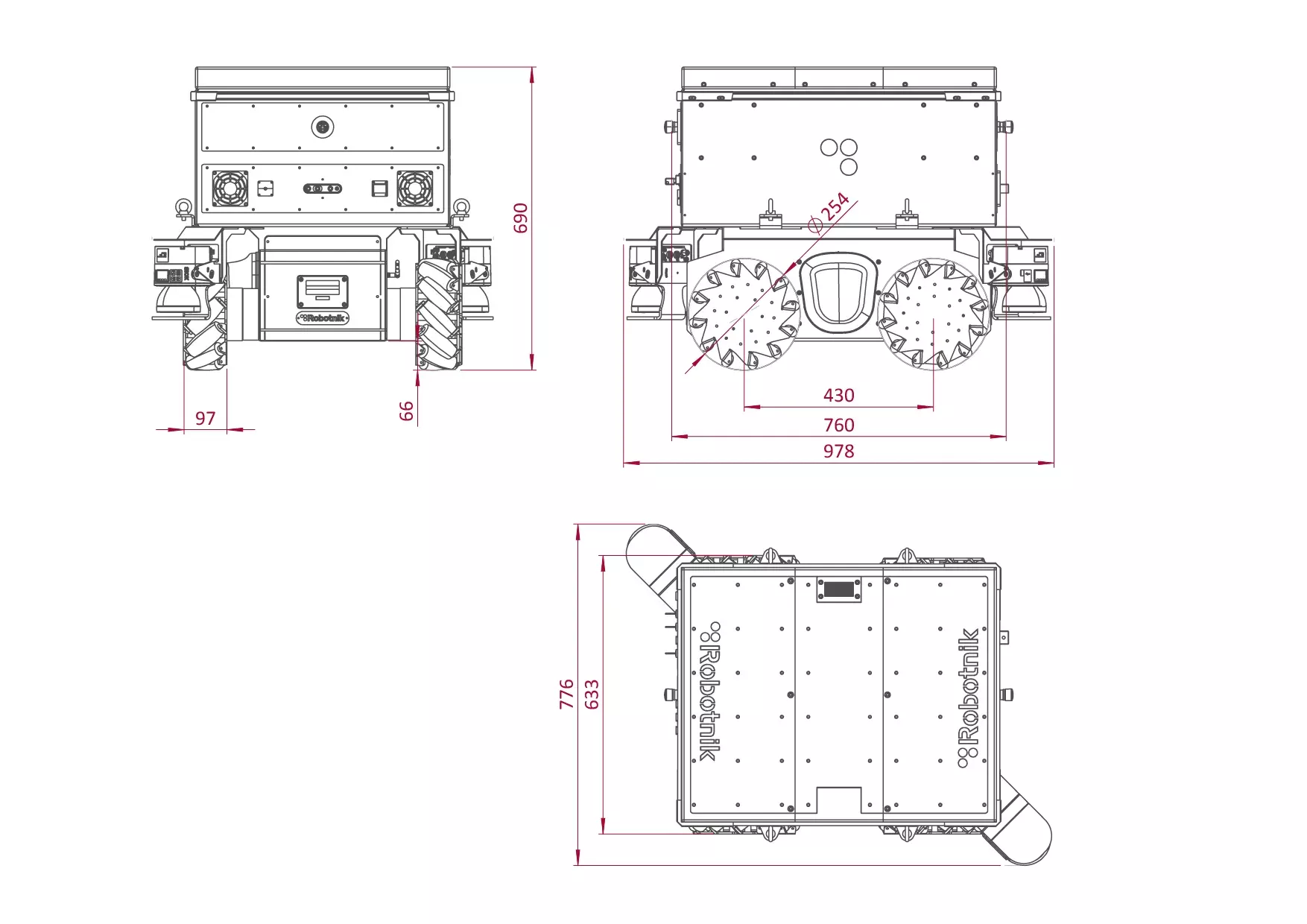

The Robotnik RB-KAIROS is an autonomous mobile robot (AMR) specifically designed for indoor applications, particularly in logistics and industrial settings. With a payload capacity of up to 250 kg, it efficiently transports materials in confined spaces, thanks to its compact, steel-framed design. Its omnidirectional Mecanum wheels allow for versatile, multidirectional movement, making navigation agile and responsive in cluttered environments, while maintaining stability and control during operations.

One of RB-KAIROS's standout features is its compatibility with Universal Robots’ e-Series arms, including models such as UR5e, UR10e, and UR16e. This compatibility allows users to transform the platform into a mobile manipulator (RB-KAIROS+), effectively extending the reach and application range of the integrated robotic arm. Its modular, ROS-based architecture supports easy customization with optional components like an AI Vision Package and enhanced payload wheels, making it ideal for applications requiring precise handling and adaptability.

RB-KAIROS is equipped with advanced safety and localization systems, including dual 2D safety scanners, RGBD cameras, and SLAM for accurate indoor navigation. With a maximum speed of 1.5 m/s and up to 6 hours of operational autonomy, it is optimized for applications in metrology, part feeding, and industrial R&D, allowing it to seamlessly integrate into smart manufacturing environments where safe, autonomous, and collaborative workflows are crucial.

What applications is RB-KAIROS product best for?

- Logistics Automation: The RB-KAIROS excels in automating indoor logistics tasks, such as transporting heavy components between workstations or storage areas, using its 250 kg payload capacity and omnidirectional movement to navigate compact spaces efficiently.

- Industrial Metrology: The RB-KAIROS+ with an integrated Universal Robots arm is ideal for metrology tasks, enabling precise measurement and quality control directly on production floors. Its mobility allows for efficient data collection across multiple locations within a facility.

- Part Feeding in Manufacturing: This AMR is particularly suited for part feeding applications in assembly lines, where it autonomously delivers parts and materials to robots or human operators, streamlining workflow and reducing downtime in manufacturing processes.