STILL Gmbh ACH Specifications

Ranked Nr. 163 of 183 Mobile Robots

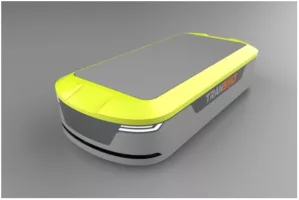

The STILL Automated Guided Cart (ACH) is a cutting-edge solution designed for industrial automation, offering a range of standout features and capabilities. One of its key strengths is its ability to achieve high throughput while requiring minimal space. This makes it an ideal choice for applications where space optimization is crucial. The ACH's compact design is made possible by its on-the-spot carrier rotation feature, which allows it to maneuver efficiently in tight spaces, ensuring maximum utilization of available area.

One of the notable advantages of the ACH is its seamless integration into new and optimized process landscapes. Whether it's integrating into existing systems or being implemented in areas specifically designed for the ACH, this automation solution offers ease of integration and adaptability. It can seamlessly fit into various industrial environments and workflows, providing a flexible and efficient solution for load handling with platforms, tables, and pallet transport.

The ACH excels in its ability to transport different carriers in tight spaces, making it a versatile option for a wide range of applications. Whether it's moving platforms, tables, or pallets, the ACH provides the flexibility needed to transport various loads efficiently, even in confined areas. This capability allows for efficient and streamlined material handling processes in industrial settings.

During the commissioning process, the ACH utilizes QR code technology, simplifying and expediting the setup and configuration. This technology streamlines the commissioning process, enabling quick and accurate identification and programming of the ACH. Additionally, the ACH utilizes precise QR code navigation for navigation purposes. This ensures accurate and reliable guidance throughout the facility, further enhancing its efficiency and performance.

In terms of specifications, the ACH is designed for short to medium transport distances. It is capable of handling different capacities, with options for 0.6 t, 1 t, and 1.5 t. The ACH achieves impressive speeds ranging from 1.2 to 2.0 m/s, ensuring swift and efficient transport operations. When it comes to pick and drop times at 90° angles, the ACH boasts minimum times of 35 seconds, contributing to its overall productivity.

During the loading process, the ACH requires a specifically defined surrounding area, which is determined during the commissioning phase. This attention to detail ensures safe and efficient loading operations. Furthermore, the ACH requires a minimum working aisle width (Ast) of 1.4 m for 90° loading, providing the necessary space for smooth maneuverability and seamless integration into existing layouts.

These specialized specifications and features make the STILL ACH a unique option for industrial automation. Its compact size, high throughput, flexible load handling, and easy integration capabilities make it an ideal choice for optimizing material handling processes in industrial environments. Whether it's transporting various carriers in tight spaces or navigating with precision using QR code technology, the ACH offers a reliable and efficient solution for industrial automation needs.

| Application |

|

| Industry |

|

| Type of Technology |

|

| Payload | 1500 kg |

| Speed | 2 m/s |