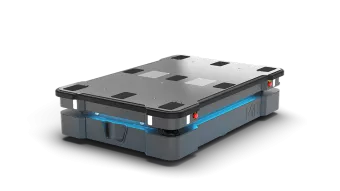

Synersight CMV Model Specifications

Ranked Nr. 1 of 183 Mobile Robots

Intended for the transport of heavy loads, offering the option of working outdoors and manual handling.

This model allows the dragging transport of heavy loads through three models, based on their capacity: 5.000, 8.000 and 10.000 Kg., all of them in internal and external logistics. They are very efficient machines, since they allow large amounts of product to be moved and the load to be hooked or unhooked automatically, thanks to the type of hook they incorporate.

Despite their robustness, they are very safe machines as they are designed with the most modern security technologies on the market.

Model:

- CMV8000

- CMV10000

| Industry |

|

| Application |

|

| Type of Technology |

|

| Navigation System |

|

| Speed | 100 m/s |