Transolt TX-10 Alternatives & Competitors

Ranked Nr. 109 of 183 Mobile Robots

Top 10 TX-10 Alternatives

- Transolt OPX-10

- Wellwit Robotics W500SL Under Ride Lifting AGV

- Wellwit Robotics W1000SL Under Ride Lifting AGV

- STÄUBLI PF3

- MoviĜo Robotics Ŝharko10 AGV/AMR

- Jungheinrich AG EKS-215a

- IBG Automation FC Load

- Kivnon K32 Tractor

- TÜNKERS TACT 1208

- Linde Material Handling C-MATIC

- MontrealRobot 2t - 150t AGV

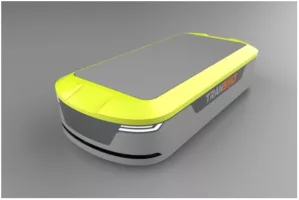

Transolt OPX-10

AGV | Payload 1000kg | Product mass 384kgTransolt OPX-10 is a highly flexible autonomous guided vehicle (AGV) that is designed to optimize material handling operations in industrial and commercial settings. One of the key features of the OPX-10 is its omnidirectional movement capability, which allows it to move sideways and diagonally with ease. This makes it particularly useful in environments where space is limited or where there are obstacles that need to be navigated around.

The OPX-10 is also highly customizable, with a variety of options available for the chassis, wheels, and other components. This allows users to tailor the AGV to their specific needs, whether they are handling large or small payloads, moving through narrow or wide spaces, or operating in clean or dirty environments.

Another advantage of the OPX-10 is its ability to communicate with other machines and systems in the facility, using a range of communication protocols such as Wi-Fi, Ethernet, and RS-232. This makes it easy to integrate the AGV into existing systems and to automate material handling tasks that were previously performed manually.

Overall, the Transolt OPX-10 is a highly versatile and reliable AGV that is well-suited for a wide range of material handling applications, from manufacturing and logistics to healthcare and hospitality. Its omnidirectional movement capability, customization options, and communication capabilities make it a valuable asset for any organization looking to improve their efficiency, productivity, and safety.

Wellwit Robotics W500SL Under Ride Lifting AGV

AGV | Payload 500kg | Product mass 220kgThe Wellwit Robotics W500SL Under Ride Lifting AGV is a highly advanced autonomous guided vehicle designed for material handling applications in manufacturing and logistics industries. This AGV features the latest LiDAR SLAM navigation technology, which enables the vehicle to navigate and operate autonomously in complex environments. This technology uses lasers to map and create a 3D image of the AGV's surroundings, allowing it to avoid obstacles and navigate through tight spaces with ease. The LiDAR SLAM navigation system also allows for real-time localization and mapping, ensuring the AGV can quickly adapt to changes in its environment.

One of the key features of the Wellwit Robotics W500SL Under Ride Lifting AGV is its impressive 500 kg payload capacity. This makes it an ideal solution for material handling tasks that require heavy lifting and transport, such as moving large crates or pallets of goods. The AGV is equipped with a high-strength lift mechanism that can easily handle heavy loads, and its compact size and maneuverability make it ideal for use in tight spaces such as factory floors or warehouses.

In addition to its impressive payload capacity, the Wellwit Robotics W500SL Under Ride Lifting AGV also offers a high level of safety and reliability. The AGV is designed with multiple safety features, including a laser safety scanner that ensures the AGV can detect and avoid obstacles in its path. The AGV also features a robust collision avoidance system that can detect and respond to potential collisions, ensuring that the AGV can safely navigate around other vehicles or objects in its environment.

Overall, the Wellwit Robotics W500SL Under Ride Lifting AGV is an advanced and highly capable autonomous guided vehicle that is ideal for material handling applications in manufacturing and logistics industries. Its LiDAR SLAM navigation technology and 500 kg payload capacity make it a valuable asset for any business looking to improve their efficiency and productivity. With its advanced safety features and reliability, this AGV is a powerful tool for streamlining operations and reducing costs.

Wellwit Robotics W1000SL Under Ride Lifting AGV

AGV | Payload 1000kg | Product mass 260kgThe Wellwit Robotics W1000SL Under Ride Lifting AGV is a highly advanced autonomous guided vehicle designed for heavy-duty material handling applications. With its impressive 1000 kg payload capacity and advanced LiDAR SLAM navigation technology, the W1000SL AGV is an ideal solution for a wide range of industries, including manufacturing, logistics, and warehousing.

The LiDAR SLAM navigation technology of the W1000SL AGV enables it to navigate autonomously in complex environments, accurately detect obstacles, and efficiently map its surroundings. This advanced technology allows the AGV to operate safely and efficiently in environments with high levels of pedestrian and vehicular traffic.

The W1000SL AGV's high payload capacity makes it ideal for heavy lifting and transport tasks, such as moving large crates, pallets, or other heavy items within a factory or warehouse. Its high-strength lift mechanism can handle heavy loads with ease, and its compact size and maneuverability make it ideal for use in tight spaces.

The W1000SL AGV is designed with multiple safety features, including a laser safety scanner that detects and avoids obstacles in its path, a collision avoidance system that can detect and respond to potential collisions, and a warning system that alerts nearby pedestrians and vehicles of its presence. These safety features ensure that the AGV can safely navigate around other vehicles or objects in its environment, making it an ideal solution for high-traffic industrial settings.

Overall, the Wellwit Robotics W1000SL Under Ride Lifting AGV is a highly capable and versatile autonomous guided vehicle that is ideal for heavy-duty material handling applications. Its advanced navigation and handling capabilities, impressive payload capacity, and safety features make it a valuable asset for streamlining operations and reducing costs in various industrial settings.

STÄUBLI PF3

Product mass 800kgStäubli's PF3 AGV platform is a premium automated guided vehicle solution that offers outstanding performance, making it suitable for a variety of industrial applications. One of its standout features is its ultra-compact design, which allows it to carry and lift payloads of up to 3 tons with high positioning precision (+/-5 mm). Additionally, its low profile and advanced safety features make it an ideal option for future-proof production and smart workflow.

The PF3 AGV platform is easy to integrate into existing production lines, thanks to its electrical and mechanical interfaces for third-party add-ons and standard software interfaces. Its advanced safety features include a human safety scanner, five emergency stop buttons, status communication with an LED strip, and collision avoidance technology. This makes it a safe and reliable solution for industrial automation.

Stäubli has used industrial-proof components in the construction of the PF3, including a unique drive unit and secured supply chain, which makes it built to last. The platform is also designed for easy maintenance, with side access to components and quick change of critical parts in just a few minutes.

Another unique feature of the PF3 AGV platform is its long-lasting design, which has up to 7,000 recharging cycles, super-fast charging up to 80A, and very robust and reliable technology.

Stäubli offers a range of add-ons and accessories for the PF3 AGV platform, including lift units with stroke +100mm, EU and US pallet adaptors, tables, and pallet stations. The PF3 is suitable for a range of industrial applications, including industrial intralogistics, assembly lines, and pallet transport. It performs tasks with subcentimeter position precision, making it a cost-effective, reliable, and flexible solution for manufacturing processes.

MoviĜo Robotics Ŝharko10 AGV/AMR

AGV | Payload 1000kg | Product mass 110kgMoviĜo Robotics Ŝharko10 AGV/AMR is a highly capable and extremely compact autonomous mobile robot designed to automate intralogistics in production environments. It is the most maneuverable industrial AGV available and operates in areas where floor space is limited. Due to its compact design, it can even navigate in tight spaces and work in areas with people.

The Ŝharko10 AGV is specifically designed to transport goods and materials in production environments. It can replace the use of manual pallet trucks or pallet jacks, reducing the need for manual labor and increasing efficiency. The AGV can transport pallets between different production or assembly lines, between production lines and warehouse, packing or shipping locations. The vehicle navigates autonomously, so no physical changes to its area of operation is required.

The Ŝharko10 AGV boasts several features, including its small dimensions which offer maximum maneuverability, its ability to communicate with hardware devices, its ability to turn within its own length, and its 7-8 hours operating time on full battery. Additionally, it can lift up to 1,000kg and can transport more than just pallets. It is WiFi-connected to the traffic control system MoviĜo Site and can navigate in dynamic environments. The AGV is also easily integrated with systems like ERP and WMS and can add and remove pick-up and drop-off points easily. Each vehicle can perform different tasks, and there is an online fleet dashboard for managing the vehicles. Finally, the AGV is easily maintained and offers extensive data collection options.

In conclusion, the MoviĜo Robotics Ŝharko10 AGV/AMR is an ideal solution for automating intralogistics in production environments. Its compact design, high maneuverability, and ability to operate autonomously make it an efficient and cost-effective solution for transport tasks. With its easy integration with existing systems and online fleet dashboard, the Ŝharko10 AGV offers a complete solution for modern production facilities looking to automate their intralogistics processes.

Jungheinrich AG EKS-215a

The Jungheinrich EKS 215a is a compact and versatile Automated Guided Vehicle (AGV) designed for efficient mixed operations in warehouses and production areas. Its standout features and capabilities make it an ideal choice for industrial automation.

One of the key features of the EKS 215a is its 24-V energy concept, which utilizes a lithium-ion battery. This concept provides maximum flexibility and ensures longer operating times, minimizing the need for frequent battery changes. Additionally, the AGV incorporates an automatic charging function, allowing it to recharge itself when needed without manual intervention.

The modular mast concept of the EKS 215a further enhances its versatility. The adjustable forks and high residual capacity enable the handling of special load carriers in stations that cannot be driven under. This feature proves particularly useful in situations where manual trucks or other obstacles are present, allowing the AGV to navigate and transport loads efficiently in such environments. Moreover, the AGV is capable of delivering loads in racks, making it suitable for various warehouse applications.

When it comes to safety, the EKS 215a boasts a future-proof safety concept. It incorporates integrated personal protection sensors that ensure a high level of safety, especially in mixed operation scenarios where manual trucks and pedestrians are present. These sensors detect the presence of individuals or obstacles, enabling the AGV to react and navigate safely in its surroundings.

The EKS 215a also prioritizes user-friendliness through its intuitive HMI (Human-Machine Interface) touch display. The touch display simplifies the interaction between the operator and the AGV, making it easier to control and monitor the vehicle's operations. This user-friendly interface enhances productivity and reduces the learning curve for operators, resulting in more efficient processes.

In addition to its standout features, the EKS 215a offers lesser-known or specialized specifications that make it a unique option for industrial automation. For example, it may have a high tolerance for extreme temperatures, allowing it to operate reliably in environments with hot or cold conditions. This capability enables the AGV to be utilized in a wide range of industries and applications, including cold storage facilities or high-temperature manufacturing environments.

Furthermore, the EKS 215a may also offer compatibility with specific software systems, enhancing its integration into existing automation setups. This compatibility allows seamless communication and coordination between the AGV and other automated equipment or warehouse management systems, optimizing overall workflow and efficiency.

In conclusion, the Jungheinrich EKS 215a AGV stands out as a compact and versatile solution for industrial automation. Its features, such as the 24-V energy concept, adjustable forks, high residual capacity, and integrated safety sensors, make it a reliable and efficient choice for mixed operations in warehouses and production areas. The user-friendly HMI touch display and potential specialized specifications, such as tolerance for extreme temperatures and compatibility with specific software systems, further enhance its capabilities and adaptability to various applications.

IBG Automation FC Load

AGV | Payload 1000kg | Product mass 450kgAutonomous forklift AGV for picking up and transporting Euro pallets or pallet cage.

Kivnon K32 Tractor

The Kivnon K32 Tractor is an AGV/AMR designed for efficient and reliable load transportation in internal logistics processes. With its one-way movement and towing capacity of up to 2,000kg, it's ideal for handling large loads.

The AGV utilizes magnetic guidance navigation for precise maneuvering and can be seamlessly integrated with fleet management systems, including those based on VDA 5050. This allows for optimized coordination and control of the AGV within the overall logistics operations.

With high precision and advanced safety measures, including laser scanners, ultrasound sensors, and a safety PLC, the K32 Tractor ensures accurate stops and secure operations. These features contribute to a safe working environment and help prevent collisions or accidents.

The K32 Tractor comes in two versions: the K32 and K32P, offering flexibility to meet different operational requirements. Its compact dimensions, with a length of 1170mm, width of 480mm, and height of 1040mm, allow for easy maneuverability in tight spaces.

The AGV is powered by either AGM or lithium batteries, offering exchangeable and online charging capabilities through an integrated circuit. This ensures continuous operation without the need for manual battery replacement.

The K32 Tractor's standout features, towing capacity, compatibility with fleet management systems, and advanced safety measures make it a reliable and efficient solution for industrial automation in various sectors.

TÜNKERS TACT 1208

AGV | Payload 1000kg | Product mass 480kgThe TÜNKERS Automated Cart TACT 1208 is a bidirectional, ramp-capable underride AGV, particularly characterised by its modular build. It adapts flexibly to different applications matching modules. This is made possible, among other things, by use of lifting table modules, gripper systems, roller conveyors, or accumulating conveyor systems.

Linde Material Handling C-MATIC

AMR | Payload 600-1500 kgThe Linde Material Handling C-MATIC is a state-of-the-art autonomous truck that guarantees maximum safety, handling efficiency, and serviceability. Its safety features include a laser scanner that detects moving or stationary obstacles in real-time, allowing the truck to adjust its speed or remain stationary until the obstruction is cleared. Additionally, the C-MATIC is equipped with a robust all-round collision protection system and emergency stop switches on all four sides. These safety features ensure the highest possible levels of safety for people and trucks.

The C-MATIC uses QR codes affixed to the hall floor along transport routes to navigate, with each QR code having a unique ID and saved as reference points on a digital map. The software calculates the optimal route for each transport order, allowing the truck to efficiently and autonomously handle material flow. The trolleys are also equipped with QR codes, which makes it possible to identify the goods to be transported, assign storage locations, and position the load carrier. The C-MATIC's optional autonomous charging station allows for automated charging of batteries, ensuring the truck is always fully charged and ready for use.

The C-MATIC’s robust technology ensures reduced service and lifecycle costs, with long maintenance intervals and easily accessible main components that allow for efficient maintenance work. This design-to-service principle also contributes to the truck’s high operational availability, while all the truck data can be read out via a cable connection for fault analysis. In summary, the Linde Material Handling C-MATIC is a reliable and efficient autonomous truck that maximizes safety, handling, and serviceability, making it the ideal solution for material handling in a range of applications.