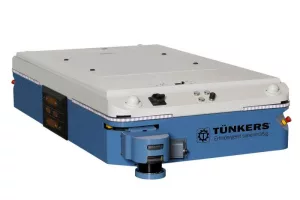

TÜNKERS TRoll 2216 Specifications

Ranked Nr. 47 of 183 Mobile Robots

The TÜNKERS Automated TRoll has an active chain gripping system that enables a fully automatic pick-up of large load carriers. The loading and unloading options on either side in combination with an omni-directional travel mode makes it particularly flexible in use. The optional 3D cameras reliably detect forklift tines in the room, for example. Digital LEDs visualise events and driving movements.

| Technology |

|

| Payload | 1000 kg |

| Product mass | 1350 kg |

| Protection (IP) | 54 |

TRoll 2216 Downloads

11 T Roll

You need to

register

to download this file.