Fabio Florian

Fabio Florian

Sep 25, 2023

Period

- 2021

Testimonial

Anonymous user

Jul 17, 2023

Period

- 2022

Ranked Nr. 8 of 207 Cobots

Choose your model

$57,000.00

Website: www.Universal-Robots.com

The Universal Robots UR20 is a next-generation collaborative robot designed to deliver superior performance, versatility, and usability, while maintaining a small footprint. With a reach of 1750 mm and a payload capacity of 20 kg, the UR20 can handle a wide range of tasks, fit various applications, and assist in many different environments.

The UR20 features a new joint architecture that allows for up to a 65% increase in speed, depending on the joint type. The redesign puts less stress on the arm mechanics, resulting in a 25% increase in joint torque capability. This design delivers next-generation performance and quality, helping you increase throughput, uptime, and get more products to market faster than ever before.

One of the primary benefits of the UR20 is that it automates repetitive, low-value tasks, reducing the risk of worker injuries and inconsistencies in production. With the UR20, you can protect your people, as 8% of manufacturing workplace injuries happen due to repetitive motions, and 24% are due to overexertion. The UR20 collaborative robot can now automate more of these tasks, freeing up your team to focus on higher value work.

The UR20 is designed with transferable expertise in mind, allowing node-based programs to provide a visual representation of the steps in the operation, making it simple to understand and optimize. Productivity in large-scale workplace setups and applications can be maintained despite labor gaps and shortages.

In addition to its performance and usability, the UR20 is ready for the future. It can build, change, save, and upload programs easily depending on the task at hand. You can optimize without downtime by analyzing and enhancing programs as they run.

The increased reach enables the further scaling of cobot automation and throughput gains to more demanding, heavier-duty applications.

PACKAGING AND PALLETIZING

Where picking, packing and palletizing of heavy parts is required, the UR20 can help customers gain efficiencies and productivity. The UR20 enables reach for standard EURO pallets, and stacking of up to 2m in height.

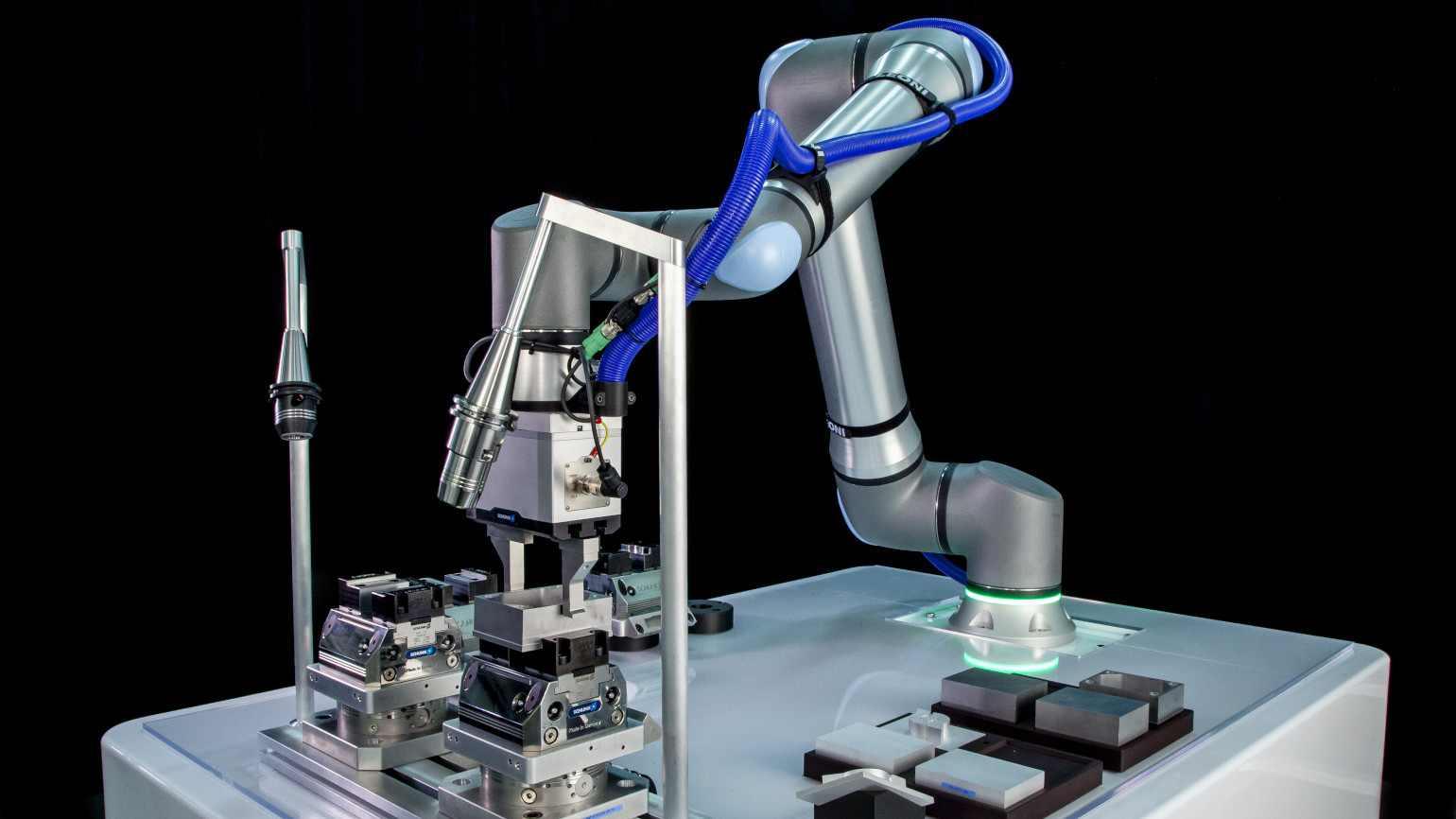

MACHINE TENDING

The UR20 offers flexible processing of a diverse range of larger dimension parts to machinery such as cutting, punching, drilling, machining and forming. Mountable in any position the UR20 easily moves around workplace objects such as machine tending doors.

PERFORMANCE ON A WHOLE NEW SCALE.

Redesigned from the ground up, the software brings unprecedented motion control capabilities to the joint architecture, achieving up to 30% greater speed and 25% higher torque within a closed capsule.

PART HANDLING AND ASSEMBLY

Greater payload allows heavier workpiece handling, as well as the option to configure two or more end effectors for even better cycle times. Manufacturing and assembly of large equipment such as diesel engines, driveline, transmission and battery assemblies often require human robot collaboration.

WELDING

In applications where reaching for long seams of parts and components is typically required, the small footprint of the UR20 enables multiple robots be used in the same production cell. New joint architecture improves motion consistency while the larger 1750mm reach geometry increases your work zone.

Fabio Florian

Fabio Florian

Sep 25, 2023

Anonymous user

Jul 17, 2023

Bob's Red Mill implemented the UR20 collaborative robot (cobot) to enhance its palletizing operations, streamlining processes and improving efficiency.

Learn more