YAMAHA Basic model (ABAS) Specifications

Ranked Nr. 16 of 33 Linear Motion Systems

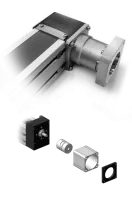

Yamaha's basic model (ABAS) is a high-performance linear actuator that is designed to meet the demands of a wide range of industrial applications. The ABAS is a compact and low-cost linear actuator that features an integrated guide rail and frame design, making it easy to install and operate.

The ABAS is designed for applications that require high moment rigidity in a compact design. Its high rigidity design ensures that it is capable of achieving precise and accurate movements even in challenging industrial environments. This makes the ABAS an excellent choice for industrial applications that require high levels of precision and accuracy, such as automotive assembly, material handling, and packaging.

The ABAS features an integrated guide rail and frame design, which helps to reduce installation time and costs. This feature makes the ABAS an excellent choice for industrial applications that require a compact and low-cost linear actuator that is easy to install and operate.

The ABAS has a maximum payload of up to 115 kg, making it suitable for a wide range of industrial applications. Its high maximum speed of 300 to 1,800mm/sec ensures that it is capable of achieving high levels of productivity and efficiency, even in challenging environments. The ABAS also has a stroke range of 50 to 1,250mm, making it highly versatile and suitable for a wide range of industrial applications.

Overall, the Yamaha ABAS is a high-performance linear actuator that is designed to meet the demands of a wide range of industrial applications. Its high rigidity, compact design, integrated guide rail and frame design, maximum payload of up to 115 kg, maximum speed of 300 to 1,800mm/sec, and stroke range of 50 to 1,250mm make it an excellent choice for any industrial application that requires high levels of precision, accuracy, and reliability in linear motion.

| Payload | 115 kg |

| Min. Stroke | 50 mm |

| Max. Stroke | 1250 mm |