YAMAHA Linear Conveyor Modules LCMR200 Pricing & Product Details

Ranked Nr. 17 of 33 Linear Motion Systems

Linear Conveyor Modules LCMR200 Pricing

Price indication:Linear Conveyor Modules LCMR200 Overview

What is Linear Conveyor Modules LCMR200?

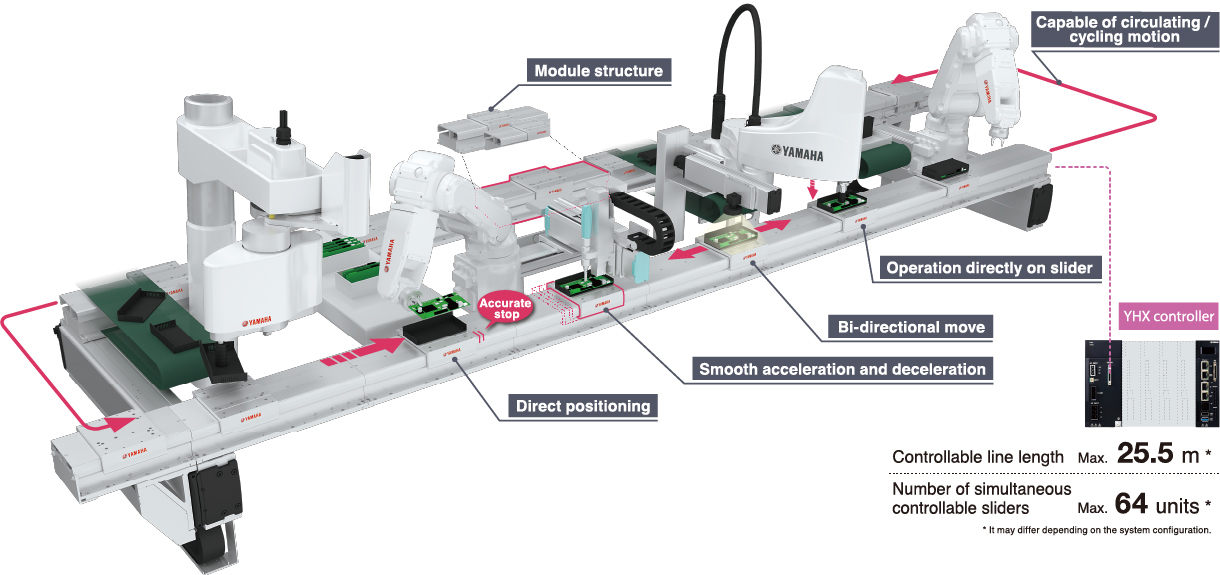

The LCMR200 Linear Conveyor Module is designed to enhance the efficiency of industrial applications in many ways. For instance, it can reduce the Tact Time in transportation, which helps improve productivity by speeding up the overall process. Additionally, its high speed transport and repeatability features make it flexible enough to accommodate a wide range of line designs, providing greater flexibility in industrial operations.

The LCMR200's easy maintenance feature ensures that maintenance activities are kept to a minimum, allowing the conveyor module to operate for longer periods without any interruptions. Furthermore, the low operation cost makes it an economical solution for industrial applications that require material handling.

The improved productivity of the LCMR200 can also be attributed to its reduced line design time, as it can easily integrate with existing systems, reducing the time and effort required for line design. The space-saving design of the LCMR200 also allows for greater floor space utilization, providing additional benefits for industrial applications that require efficient use of space.

Finally, the LCMR200 Linear Conveyor Module's durability ensures that it can withstand the harsh conditions and demands of industrial environments, providing reliable and long-lasting performance. Examples of applications that can benefit from the LCMR200 Linear Conveyor Module include assembly lines, material handling, packaging lines, and other industrial processes that require efficient and precise material transport.

What applications is Linear Conveyor Modules LCMR200 product best for?

The Yamaha LCMR200 Linear Conveyor Module is best suited for industrial applications that require high-speed and highly precise transport of materials. Its high level of repeatability and precision make it ideal for industries such as semiconductor, electronics, and automotive manufacturing, where precision and accuracy are critical. Additionally, its minimum spacing between robot sliders and versatile design make it a great choice for a wide range of automated material handling systems. Its features, including easy maintenance, low operation cost, and space-saving design, also make it suitable for use in various industrial settings, including clean rooms and other controlled environments.