ZIVID Zivid Two Specifications

Ranked Nr. 23 of 97 3D Vision Systems

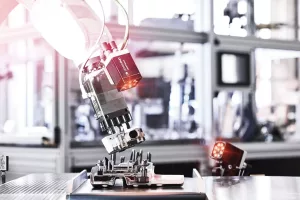

Human-like vision for pick and place robotics.

Zivid Two gives you exceptional 3D image quality lightning fast in an ultra-compact form-factor. Design fast, reliable pick and place robots cells capable of handling a wide variety of challenging objects and scenes.

High quality, native color 3D point clouds for better object recognition.

See tiny objects and the fine details.

High resolution and precision point clouds of even very small, densely packed or highly detailed objects. Distinguish features smaller than 5 mm.

2.3 Mpix- HD resolution

55 μm- Point precision

Minimal occlusion- 112 mm baseline

See reflective and shiny objects.

Take images of traditionally challenging parts such as sheet metal, machined and polished parts, glossy packaging, semi-transparent and plastic wrapped objects. Excellent suppression of artifacts from reflections, interreflections, specular highlights and high contrast transitions.

ART- Artifact Reduction Technology

3D HDR-High Dynamic Range

See a wide variety of objects.

The unique combination of native color and high dynamic range enables imaging of a broad range of objects. Plastic, ceramic, metal, cardboard, wood, colored, textured, light, dark and absorptive. Single or mixed SKU bin scenarios, densely stacked or randomly arranged.

3D RGB- Native colors

White light- Broad material coverage

Pick with confidence

True to reality 3D point clouds for more accurate and reliable grasping and manipulation.

Accurate picks and fine manipulation.

Point clouds with true to reality representation of object size, rotation, and absolute position. Enables demanding pick and place operations and gives flexibility in choice of gripper.

< 0.2% at focus distance -Dimension trueness error

3D hand-eye calibration- 10x more accurate

Less mispicks and crashes.

Minimal trueness drift and variation across the full operating temperature range and under mechanical stress from handling and use.

Floating thermal calibration

Mechanical and thermal stability

Work faster.

Improved cycle time with fast 3D point cloud captures.

<100 ms capture time.

Low to medium dynamic range scenes. Wide variety of objects in all shades, except the darkest black and absorptive.

<300 ms capture time.

High dynamic range scenes. Highly shiny and reflective, white and dark absorptive objects in the same scene.

<1s capture time.

Extreme dynamic range scenes or longer working distances. Highly specular, chrome plated and mirror like. Objects positioned with steep angles away from the camera and super absorptive absolute black objects.

On-arm versatility.

Unleashing the potential of on-arm mounting in pick-and-place robotics.

Unrestricted movement.

Compact, lightweight and fast 3D camera for on-arm mounting for even smaller collaborative robots. Minimum impact on maneuverability, usable payload and cycle time.

169 x 122 x 56 mm-Palm sized

940 grams- Maximize robot maneuverability

60 ms- Minimize acquisition time

Extended field of view.

Leverage on-arm camera to cover larger bins, pallets and flow racks. Use a single on-arm camera for multiple bins or pallets.

Multi-view imaging.

Capture images from multiple or different viewpoints to improve object recognition and reliably empty the bin.