Today, warehouses and factories use high-tech tools to work faster and better. One such tool gaining popularity is the Automated Guided Vehicle (AGV). AGVs are robots that help with different jobs in these places.

There are different types of AGVs, like Cart AGVs, smart AMRs, and tough Outdoor AGVs. Each one is made for specific tasks.

In this article, we’ll learn all about AGVs. We’ll see what makes them special, get useful advice, and find interesting facts to help you pick the right AGV for your needs.

But first, let’s start with:

What is an AGV?

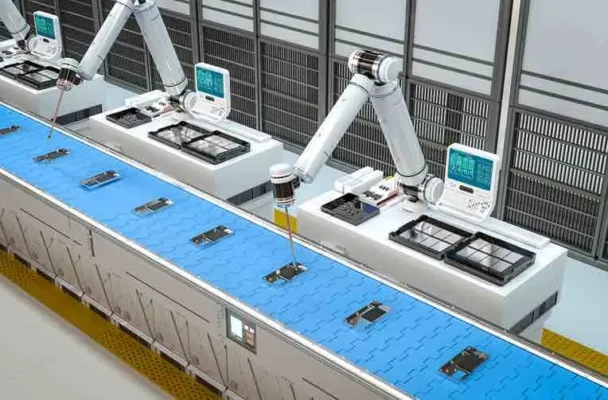

An Automated Guided Vehicle (AGV) moves materials around without needing a person to drive it. AGVs follow specific paths set out for them, which can be marked on the floor or guided by more high-tech means like lasers or cameras. They’re great for doing the heavy lifting, from bringing raw materials where they need to go to carrying finished products to their final spots.

Using AGVs means fewer mistakes and accidents, as they’re programmed to do their job precisely every time. They fit right into any place that makes or stores things, helping get materials from point A to point B quickly and safely. By taking over the boring or tricky moving tasks, AGVs free up people to focus on other important work, making the whole operation run smoother and faster.

How Does an AGV Work?

AGVs have a brain, which is really just a computer, that tells them where to go and what to do. They follow a set path laid out in their environment, which can be marked on the floor with tape, wire, or magnets, or they might use lasers, cameras, or GPS if they’re more high-tech.

When you tell an AGV to move something from point A to point B, it uses its built-in sensors to see the world around it, making sure it doesn’t bump into anything or anyone on its way. These sensors help the AGV to stop if something crosses its path unexpectedly, keeping things safe.

AGVs are part of a bigger system that’s all about making things run smoother and faster, without making mistakes. They can be told what to do from a central computer, which keeps track of everything they’re carrying and where everything needs to go. This smart coordination helps factories and warehouses get more done with less effort, reducing costs and making the workplace safer and more efficient.

What are the Main Differences Between an AGV and an AMR?

AGVs and AMRs are both types of robots that help move things around in places like factories or warehouses. The big difference between them comes down to how they find their way.

AGVs follow a set path that you lay out using tapes, wires, or magnets on the floor. This makes AGVs really good for jobs where they do the same route over and over again. But if something blocks their way or if you want to change their route, you’ll have to make those adjustments yourself.

AMRs, however, are more like self-driving robots. They use cameras and sensors to see what’s around them and figure out the best way to get to where they need to go. This means AMRs can dodge obstacles, decide on new paths by themselves, and don’t need you to change the environment for them to work well. They’re great for places where things are always moving around, and you need a robot that can keep up with the changes.

So, if you need a robot for simple, unchanging tasks, an AGV could be right for you. But if you’re looking for something that can adapt to different situations on its own, you might want to consider an AMR.

Now, let’s dive into the details:

7 Types of AGVs:

1. Cart AGV:

Cart AGVs are like the hard workers of moving stuff in warehouses and factories. They have a flat surface to put things on and are really good at carrying stuff of different sizes and weights. They can handle items from a few kilograms to several tons. These AGVs are also smart; they can see obstacles and avoid them using technology like LiDAR, which makes sure they move safely even when things change around them.

Tip: If you want to make the most of a Cart AGV, think about how big and heavy your stuff is. Pick an AGV that can carry the right weight, and make sure it can move around your place without any problems.

Cart AGV (agvnetwork)

2. Forklift AGV:

When you need to move big, heavy stuff on pallets or in boxes, robot forklifts are a great choice. These AGVs work a lot like regular forklifts, with arms to lift and carry really heavy things. They can carry loads from about 1,000 kilograms to over 10,000 kilograms, making them perfect for warehouses and places where things are sent out. When you use them with Warehouse Management Systems (WMS), it helps plan the best way to load stuff, find the right route, and keep track of everything in the warehouse. This makes warehouses work better.

Tip: Think about how heavy the things you usually move are. Pick a Forklift AGV that can handle that weight. Also, check if it has safety features to avoid accidents.

Forklift AGV

3. Towing AGV:

When you need to move many carts or equipment at once, Towing AGVs are a big help. They’re made to pull other things behind them, making it easy to move stuff around. These AGVs can connect to and disconnect from the things they’re towing all by themselves, which makes them flexible and adaptable. To choose the right Towing AGV, you need to think about how many carts or equipment you want to tow and how heavy they are.

Tip: Think about how many carts or equipment you need to move and how heavy they are. Make sure the Towing AGV can handle all that weight. Also, check if it can connect to your carts or equipment.

Towing AGV (jbtc)

4. Unit Load AGV:

Unit Load AGVs are pros at moving things like pallets or containers. They’re often seen in warehouses, distribution centers, and factories, where they make moving stuff around more efficient. These AGVs can carry different weights, from a few kilograms to several tons, and they fit right into your existing racks or storage systems. Some even use RFID technology to automatically know what’s on the pallets or in the containers, which helps with keeping track of things.

Tip: Think about how big and heavy the materials you need to move is. Pick a Unit Load AGV that can handle that weight and works with your storage setup. Check if it has ways to keep the load stable for safe transport.

Unit Load AGV (agvnetwork)

5. AMR (Autonomous Mobile Robot):

Autonomous Mobile Robots (AMRs) are super versatile in AGV technology. They use smart sensors, mapping, and AI to move around on their own, even in changing places. AMRs can do lots of jobs, like moving things and picking orders. To pick the right AMR, think about what you need it to do, like general moving or special tasks. Check how well it can navigate, how long the battery lasts, and if it works with your software.

Tip: Think about what you need the AMR to do and how well it needs to move. Check its navigation skills, battery life, and software compatibility. This way, it fits well into your system.

6. Outdoor AGV:

Outdoor AGVs are made to work in challenging places like construction sites, ports, or outdoor storage yards. They are strong and can carry heavy things, even in bad weather. Some use GPS to find their way in large open areas. When choosing an Outdoor AGV, think about the outdoor tasks you need it for, how much weight it can carry, how tough it is, and if it can handle rough weather.

Tip:Decide what outdoor jobs you have, like moving heavy stuff or handling containers. Check if the Outdoor AGV can carry the weight you need and handle tough conditions. Also, make sure it can move on rough terrain.

7. Mobile Picking Robot:

Mobile Picking Robots are special AGVs for filling orders and picking things in warehouses or online stores. They have robot arms or grippers to grab individual items or small packages very precisely. They use smart machine vision and AI to pick things accurately and fast. To pick the right Mobile Picking Robot, think about the size and weight of the things you’re picking. Check if it can carry the weight, how it grabs things, and if it works with your inventory system and current processes.

Tip: Think about the size and weight of the items you’re picking. Make sure the Mobile Picking Robot can carry the weight, grab things well, and fit into your existing work system.

Mobile Picking Robot (Robotics 24/7, 2020)

Conclusion:

AGVs, or smart robots, are here to make your warehouse or factory work smoother. They come in various types, each designed for specific tasks—like moving heavy loads or picking orders with precision. This article helped you understand AGVs: their types, functions, and how to choose the right one for your needs. Now you know whether you need a heavy-lifter for outdoor tasks or a quick picker for your orders. Choosing the right AGV means aligning it with what you need most, ensuring your operations become more efficient, safe, and ahead of the curve. Ready to pick the perfect AGV?

Do you want to compare different AGVs?

Explore the potential of AGVs and join our community at Qviro to connect with industry experts and make informed decisions for your business. Join Qviro Community