Think sanding is all about manual work and sore arms? Meet cobot sanding. This breakthrough in industrial automation lets robots do the sanding for you. These cobots work right beside you, transforming not just the ease but also the safety of sanding tasks. In this read, we’ll get into what cobot sanding really means and the five big wins it brings to your production floor.

Ready to see how these smart helpers can boost your work?

Let’s dive in.

What is a Cobot?

A cobot is like a robot teammate for you. It’s built to work right next to you, safely. Imagine a robot that hands you tools or does boring tasks without getting tired. That’s what a cobot does.

These robots have special sensors. If you get too close, they stop or slow down to keep you safe. They’re easy to use, fit into tight spots, and you can teach them different jobs quickly. Perfect for any business size, cobots help you do more work, safely and efficiently. Ready to step up your game? Cobots are here to help.

Now What is Cobot Sanding?

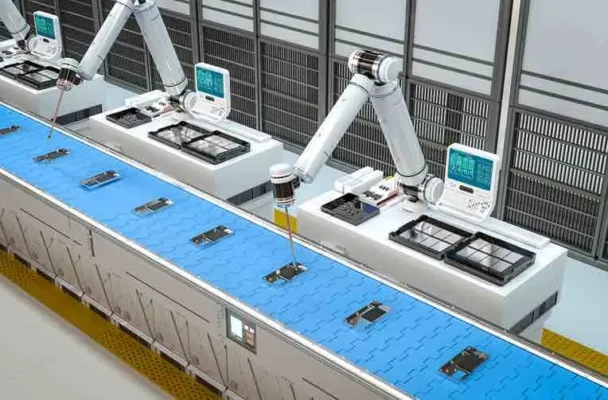

Cobot sanding is when robots, known as cobots, team up with you to tackle sanding jobs. Unlike traditional robots hidden behind safety barriers, these cobots share your workspace, safely. They’re designed to handle the sanding tools, automating the process that you’d typically do by hand.

Here’s how it works: You attach a sanding tool to a cobot’s arm. Then, you program it for the task at hand, whether it’s smoothing down a piece of wood or buffing a metal surface. The cobot goes to work, mimicking the movements and pressure you’d apply, but with robotic precision and without getting tired.

You might wonder, “Is this for me?”

If you’re in manufacturing, woodworking, or auto repair, cobot sanding can be a game-changer. It’s not just for the big players either. Small and medium businesses can also jump on board, thanks to the cobots’ affordability and ease of setup.

In essence, cobot sanding is about upgrading your production line. It’s about letting robots do the heavy lifting (or in this case, sanding), so you can focus on the finer details of your craft. Plus, it’s a step towards a future where humans and robots collaborate more closely than ever before.

5 Benefits of Using Cobot Sanding for Your Manufacturing Needs:

Let’s dive into the heart of what makes cobot sanding a game-changer for your production line. Here are the top five benefits that really stand out:

1. Increased Efficiency & Productivity:

Cobot sanding speeds things up. These robots work non-stop, cutting down the time it takes to sand parts. Imagine finishing your sanding jobs faster than ever, without compromising on quality. That’s what cobots bring to your workspace.

2. Improved Worker Safety:

Sanding can be risky, but cobots change the game. They take on the dangerous tasks, reducing your exposure to dust and repetitive strain injuries. With cobots, you’re not just getting a helping hand; you’re getting a safer work environment.

3. Enhanced Quality & Consistency:

Cobots are precise. They apply the same pressure and speed every time, ensuring each part is sanded just right. Say goodbye to inconsistencies in your work. With cobot sanding, excellence becomes the new standard.

4. Flexibility & Scalability

Need to switch tasks? No problem. Reprogramming cobots for different sanding jobs is easy. They adapt to your changing needs, making your production line more flexible and ready to grow.

5. Cost-Effectiveness

Investing in cobot sanding pays off. While there’s an upfront cost, the long-term savings in labor and increased productivity make it worthwhile. Plus, the efficiency gains mean you can take on more work, boosting your bottom line.

In short, cobot sanding offers a win-win scenario. It’s about doing more, safer, and better, without breaking the bank. Ready to take your production to the next level? Cobot sanding is the way to go.

4 Tips When Implementing Cobot Sanding in Your Operations:

Thinking about bringing cobot sanding into your workspace? It’s simpler than you might think. Here’s a quick guide to get you started on this transformative journey.

1. Choose the Right Cobot:

First up, you need a cobot that fits your specific sanding tasks. Look for one that’s compatible with the materials you work with and the size of the parts you’re sanding. Not all cobots are the same, so picking one that matches your needs is crucial.

2. Select the Proper Sanding Equipment:

Next, find the sanding tool that attaches to your cobot. Whether you’re dealing with wood, metal, or anything in-between, there’s a tool out there for you. Make sure it’s one that the cobot can handle effectively.

3. Train Your Team:

Your team needs to know how to work alongside these new robotic colleagues. Training is key. It’s about ensuring safety and maximizing the cobot’s potential. Luckily, cobots are designed to be user-friendly.

4. Start Small:

You don’t have to overhaul your entire production line overnight. Begin with a pilot project. Pick a task that’s easy to automate and see the difference cobot sanding makes.

Implementing cobot sanding is about making a smart move towards efficiency and safety. With the right cobot, equipment, and training, you’re setting yourself up for success. Ready to make your operations smoother and safer? Cobot sanding is the way forward.

Overcoming Challenges with Cobot Sanding:

Integrating cobot sanding into your operations might seem daunting at first. But don’t worry, we’ve got you covered. Here’s how you can tackle common challenges head-on and make the most out of your cobot sanding journey.

Adjusting to New Tech:

Feeling overwhelmed by new technology is normal. Start small. Choose one cobot sanding task and expand as you get comfortable. Remember, practice makes perfect.

Finding the Right Fit:

Not every cobot is right for every job. Take your time to research and select a cobot that suits your specific sanding needs. It’s about finding the perfect match for your materials and tasks.

Training Your Team:

Your team might be new to cobots. Offer them training sessions. This boosts confidence and ensures safety. Plus, it helps your team and cobots work in harmony.

Maintaining Your Equipment:

Like any tool, cobots need care. Regular maintenance keeps them running smoothly. Schedule check-ups to avoid downtime and ensure longevity.

Adapting Processes:

Your current processes might need tweaks to accommodate cobots. Be open to change. Sometimes, a small adjustment can lead to big improvements in efficiency and output.

Facing these challenges might seem tough, but with the right approach, you’ll navigate them with ease. Embrace cobot sanding, and you’ll soon see how these smart machines can transform your work for the better.

Conclusion:

Cobot sanding is a game-changer for you. It boosts your speed, keeps you safe, and ensures every piece is perfect. It’s great for any size business, ready to make your work easier. Jump into cobot sanding, and watch your productivity and safety soar. This is your chance to innovate and lead. Ready to start? Your next big step in manufacturing begins now.

Do you want to compare different Cobots?

Join our community to explore more about cobot sanding and connect with industry experts to revolutionize your production line! Join the Qviro Community

Are you looking for a System Integrator?