Diving into cobots? Great choice! They’re set to make your factory smarter and more flexible, all without the hefty price tag of traditional automation. But, it’s not all smooth sailing. You might hit some snags with operation, safety, and even data security. No worries, though. We’ve got your back with tips and tricks to pick the perfect cobot.

Ready to boost your manufacturing line and tackle those challenges head-on?

Let’s dive in.

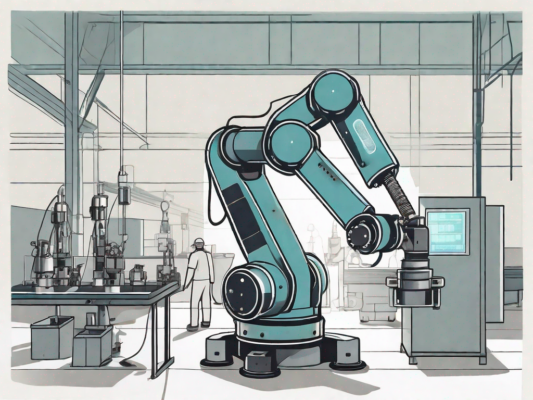

What is a Cobot?

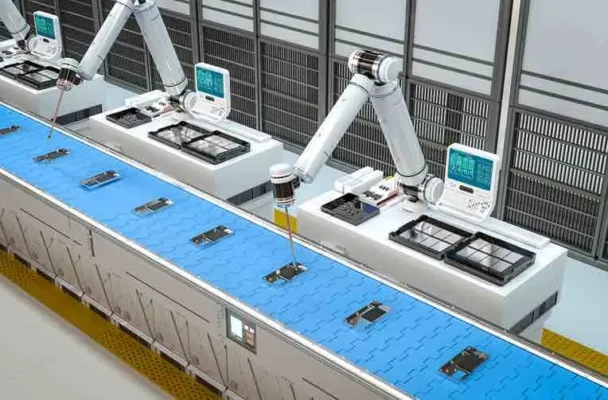

A cobot, short for collaborative robot, unlike traditional robots, cobots are designed to work alongside humans, making your job easier, not replacing it. They’re the extra pair of hands you didn’t know you needed, handling tasks from assembly to packing, all without needing a cage.

Cobots are smart, safe, and incredibly flexible. They can adapt to different tasks quickly, thanks to easy programming. Safety is a top priority; they’re built to stop or slow down if they bump into you, ensuring a safe work environment.

Plus, they’re lightweight and don’t take up much space, fitting perfectly into small work areas. Cobots are all about boosting productivity and making your manufacturing line more efficient, without the complexity or cost of traditional automation.

Common Challenges:

1. Operational Challenges:

Speed & Payload Limitations:Your cobots aren’t built for speed or heavy lifting. They move safely at around 250mm per second, which keeps them safe around people but might slow them down for some tasks. Also, they’re more about finesse than brute strength, handling lighter loads best. If you need quick or heavy lifting, cobots might not be your go-to.

Consistent Workstation Setup: To get the best out of them, keep their workspace the same. Changing their environment too much means they have to be re-taught their tasks, which takes time and effort. A stable setup means your cobot can do its job efficiently without extra hassle for you. Think of it as setting up a comfortable, unchanging workspace that helps them (and you) work better.

Advice: To keep cobots working well, be adaptable and make small changes in your operations. Be careful about how you organize your workspace and stick to guidelines for the best outcomes.

2. Human Involvement & Supervision:

Cobots Need Help: Cobots can work alone, but they often need people, especially at night when fewer folks are around. Humans are super important for dealing with surprises and making tough choices that cobots might find hard.

Advice: Understand the need for human supervision, and make sure you have enough staff to support cobot operations. Create clear ways for humans and cobots to communicate and work together effectively.

3. Safety Considerations:

Cobots Have Limits: Cobots can’t lift heavy stuff or go really far. They’re good for things between three to ten kilograms, but big robots can handle much heavier loads, up to two tonnes. This makes it tough to use cobots in heavy industries.

Safety Approvals Are Complicated:Making sure cobot workplaces are safe is tricky. It means getting different safety approvals, and that can be complex. If you change what the cobot does or where it works, you might need more permissions. Even though it’s for safety, it can slow things down with extra paperwork.

Advice: To make things smoother, create a virtual model of your workspace to understand risks. By planning and solving problems early, you can reduce safety concerns and speed up the approval process.

4. Privacy & Security:

Ownership of Data:We need to know who owns and keeps safe the data cobots make. It could be the user, the cobot maker, or the software provider. This is super important for keeping your company’s private info safe.

Advice: To keep your data safe, it’s a smart idea to use cobots offline, not linked to the internet. This way, your data stays private and secure, and unauthorized people can’t get to it. If you need internet access, be sure to connect the cobots to a safe local network to protect your important data.

Conclusion:

Wrapping up, choosing cobots is a smart step for your production line. These robots boost your efficiency and adapt easily to your needs, handling tasks smoothly. Sure, you’ll meet some challenges, like setting them up correctly and keeping everyone safe. But, with the right knowledge and attention to detail, you’ll navigate these issues just fine.

The aim? To streamline your operations and make your job simpler. Cobots are your path to staying ahead in the manufacturing game.

Do You Need To Compare Different Cobot Models?

Ready to tackle cobot challenges and boost your manufacturing line? Join our community at Qviro Community to connect with experts and find the perfect cobot solutions for your needs!

Are you looking for a System Integrator?