Stepping into industrial automation? Crafting an RFQ (Request for Quotation) is your key move. It might seem daunting, but it’s your ticket to finding the right automation gear without overspending. An RFQ is your way to tell suppliers exactly what you need for your production line. It’s about getting clear on your project’s demands and kicking off the hunt for the best fit.

Ready to simplify this process?

Let’s dive into making your RFQ journey straightforward, ensuring you get the perfect automation solutions on budget.

What is an RFQ?

An RFQ (Request for Quotation) is essentially your shopping list for industrial automation. It tells suppliers what you need for your manufacturing line. You might be looking to boost your current setup or bring in brand new tech. Either way, an RFQ spells out the details: what machines you’re eyeing, their specs, and your must-haves.

What you are saying when you write an RFQ is, “Here’s what I want. What’s your best offer?” This step is crucial. It lets you weigh your options, ensuring you pick automation gear that not only fits your budget but also meets your technical needs. Nailing your RFQ means you’re on the right track to making your production line more efficient and powerful.

RFQ vs RFP vs RFI: What’s The Difference?

When you’re upgrading your production line, you’ll run into two key terms: RFQ and RFP. They might sound alike, but they play different roles in getting you the right automation gear.

RFQ:

An RFQ (Request for Quotation) is straightforward. You tell suppliers exactly what equipment you need and ask, “How much?” It’s all about finding out the price for specific items on your list.

RFP:

RFP (Request for Proposal), however, goes deeper. It’s like asking suppliers, “Here’s my challenge. How would you fix it?” You’re not just looking for prices; you’re looking for comprehensive solutions. This includes the equipment, services, and their strategy to meet your automation needs.

So, here’s the deal: Use an RFQ when you know what you need and just want the best price. Use an RFP when you’re open to ideas on how to solve your automation challenges and want a package that offers great value, not just a low cost.

RFI:

An RFI (Request for Information), is your research phase when you’re looking into buying something. It’s where you ask suppliers to tell you all about what they offer—products, services, and what makes them stand out. It’s not about asking for prices or proposals yet.

Instead, an RFI helps you understand what’s out there in the market. It’s your tool for comparing suppliers, getting your facts straight, and figuring out who might meet your needs best. By sending out RFIs, you’re laying the groundwork to make sure your next steps, like asking for bids, are on point.

Choosing the right approach can make a big difference in finding the perfect match for your project.

Understanding Your Needs When Writing an RFQ:

Before you rush into drafting an RFQ or RFP, you need to nail down what your production line actually needs. Think about it like diagnosing before treating. It’s not just about grabbing any shiny new tech; it’s about finding what fills the gaps in your setup.

First off, take a good look at your current operations.

Ask yourself:

- “Where are we lagging?

- What tasks are eating up our time?”

This could range from manual work that’s too slow to tasks screaming for automation. Pinpointing these issues helps you zero in on the type of automation that’ll truly make an impact.

Next up, get specific about what you want to automate. Is it packaging, assembling, or something else? Identifying the task will guide you to the right technology for the job.

Also, consider how this new tech will mesh with what you already have. Will it play nice with your current systems? Compatibility is crucial for a smooth upgrade and getting the most out of your new setup.

Taking this step to fully understand your needs is key. It ensures you’re investing in automation that doesn’t just look cool but actually boosts your production line’s efficiency.

Key Components of an RFQ for Industrial Automation:

Crafting an RFQ for industrial automation? Here’s how to make yours clear, concise, and effective. Let’s break it down into key parts.

Define Your Project:

Start by outlining your project. This means telling suppliers exactly what you’re looking to automate. Are you upgrading? Adding new lines? Be clear and concise.

Specify Your Requirements:

Detail what you need. This isn’t just about the machines. Think about the tasks you want to automate and the outcomes you’re aiming for. Do you need something for packing, assembling, or maybe quality checking? Spell it out.

Technical Specs:

Get into the nitty-gritty of technical requirements. This covers everything from speed and accuracy to size and compatibility with existing systems. Suppliers need these details to offer you the right solutions.

Budget and Timeline:

Be upfront about your budget and timeline. Knowing your financial limits and when you need the automation up and running helps suppliers tailor their quotes to fit your constraints.

Ask for References:

Request references or case studies. Seeing how suppliers have solved similar problems for others can give you confidence in their capabilities.

Support and Training:

Don’t forget to ask about support and training. You’ll want to know how they’ll help you get started and keep things running smoothly.

Warranty and Service:

Inquire about warranties and service agreements. Understanding how issues are handled post-purchase is crucial for long-term success.

Creating a detailed RFQ is your first step towards finding the right automation solution. By being specific about your project, needs, and expectations, you invite suppliers to offer you their best solutions, tailored to your unique situation.

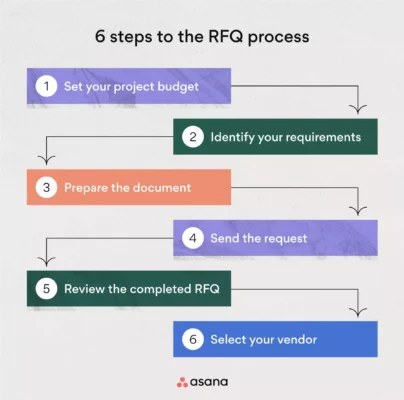

Asana has a great breakdown for a RFQ for general purposes.

8 Writing Tips for Clarity and Precision:

Writing an RFQ for industrial automation? Clarity and precision are your best friends. Here’s how to keep things crystal clear:

1. Be Specific: Don’t just say you need a robot. Specify the type, capabilities, and functions. Need a robot for packaging? Mention the size, weight of packages, and speed required. The more details, the better suppliers can match your needs.

2. Use Simple Language: Skip the jargon unless it’s industry standard and crucial for understanding. Your goal is to be understood, not to impress with technical lingo.

3. Bullet Points Are Your Ally: Lists make it easier to digest information. Break down your requirements, specifications, and questions into bullet points.

4. Include Examples: If possible, reference similar projects or products. This gives suppliers a concrete idea of what you’re looking for.

5. Be Clear on Quantities: How many units do you need? Be precise to get accurate quotes.

6. Specify Your Timeline: When do you need it? Set clear deadlines for delivery.

7. Budget Constraints: If you have a budget in mind, mention it. This helps suppliers tailor their proposals to what you can afford.

8. Ask for References: Request examples of similar projects the supplier has completed. This helps gauge their experience and capability.

By sticking to these tips, your RFQ will be a beacon of clarity, attracting the right suppliers with the right solutions. Remember, the goal is to make it easy for suppliers to understand and meet your needs, leading to better, more targeted proposals for your project.

6 Tips in Evaluating Proposals:

Once you’ve sent out your RFQ and the proposals come rolling in, it’s decision time. Evaluating these proposals is more than just looking at numbers. You want to ensure you’re picking the best fit for your automation needs. Here’s how to do it:

1. Match with Requirements: Go back to your RFQ. Does the proposal check all your boxes? Make sure the supplier has addressed each of your specified needs, from the type of equipment to its capabilities.

2. Price Comparison: Look at the cost, but don’t let it be the only factor. The cheapest option isn’t always the best. Consider value for money.

3. Supplier Experience: Who’s behind the proposal? Check their track record in industrial automation. Experience can be a deal-maker.

4. Technology Fit: Is the proposed solution compatible with your current setup? It should integrate seamlessly into your line.

5. Support and Maintenance: What kind of after-sales support does the supplier offer? Reliable service and maintenance are crucial for long-term success.

6. Delivery Time: Can they meet your timeline? Delays in delivery can set back your entire project.

By focusing on these points, you can sift through the proposals with a keen eye, ensuring you select a solution that not only meets your immediate needs but also supports your long-term production goals. It’s about finding a partner who delivers quality, reliability, and value, ensuring your automation upgrade is a success.

Leveraging Technology:

Embracing technology in your factory is more than just an upgrade; it’s a game-changer for your production efficiency, flexibility, and edge over competitors. Here’s your playbook:

1. Spot the Shortfalls: First, figure out what’s missing. Slow production? Errors? Safety concerns? Identifying these issues points you to the tech solutions you need.

2. Keep Learning: The tech landscape keeps changing. Stay on top of new gadgets and methods. Attend online workshops, visit trade expos, or read up on industry news to keep your edge.

3. Tailor-Made Tech: Forget one-size-fits-all. Seek out tech that can be customized for your specific production challenges. This personal touch can significantly boost your output.

4. Seamless Fit: Pick tech that easily integrates with what you already have. Smooth integration means less downtime and more work done.

5. Train Your Team: A new gadget only works as well as the people using it. Make sure any tech you bring in comes with training and support for your crew. This way, they can make the most of it from day one.

6. Think Ahead: Choose tech that grows with you. Your needs will change, and so should your equipment. Opt for scalable, adaptable solutions to stay ahead like Match.Qviro

By smartly using technology, you make sure your production line isn’t just keeping up but leading the pack. It’s not just about having the latest tools; it’s about using them strategically to hit your targets.

Conclusion:

Jumping into industrial automation is a smart step to boost your production line’s efficiency and edge. Here’s what to keep in mind: write clear RFQs, really get what you need, pick the tech that fits, and carefully look at each proposal. Dive into this journey, keep up with new tech, and be detailed about what you want. Doing this not only gets you the best automation solutions but also revamps your manufacturing process for the better. Start this adventure with confidence, ready to make your production smarter, more innovative, and way more efficient.

Do you want to compare different types of industrial automation?

Wow! Finally I got a website from where I know how to really take valuable information concerning my study and knowledge.

Hi there, I just discovered your blog through Google and found it to be really informative. I’m going to keep an eye out for future updates. I would be grateful if you continue this in the future. Many people will benefit from your writing. Cheers!