Robotic cable management might not be the first thing you think of when optimizing your manufacturing line. But it should be.

Good cable management ensures that your robots perform optimally, reduces the risk of unexpected breakdowns, and extends the lifespan of your equipment.

It’s not just about preventing a tangle of wires; it’s about ensuring your robotic systems run smoothly.

In this guide, you’ll learn not only the potential risk of bad cable management, but also how to properly maintain your robotic cables.

What are the Different Types of Cables in Robotics?

When it comes to cable management in robotics, you’re not just dealing with one type of cable.

There are three main types, each serving a distinct purpose. It’s crucial to understand these to manage them effectively and ensure your robot operates smoothly.

Power Cables:

These are the lifelines for electric robots, providing the essential electricity to power both the robot and its tool. Without these, your robot is just a stationary piece of metal. The proper management of power cables is crucial to prevent power disruptions and to maintain the efficiency of your robot’s operations.

Communication Cables:

These are the conduits for signals that command and control your robot. They carry communication signals to the robot and tool, functioning as either digital or analog signals. The integrity of these cables is vital. Any damage or mismanagement can result in miscommunication, leading to errors in the robot’s operation or, even worse, complete malfunctions.

Pipes:

An often overlooked aspect of robotic cabling. Certain tools require additional resources to operate, like pneumatic vacuum grippers. These tools need pneumatic pipes. Other variations might need pipes for hydraulics, gas, or other fluids. These pipes, while not electrical, are just as important as the cables. Their damage or misplacement can lead to tool malfunction, affecting the overall productivity of your robot.

6 Common Failures in Robot Cable Management:

You might think that once you’ve set up your robot’s cables, you’re good to go. But it’s not that simple. Cables can fail, and when they do, it’s not just a nuisance – it can bring your entire operation to a standstill. Let’s delve into the six common failures you need to watch out for.

Loss of Continuity:

This is a sneaky one because it builds up over time. Small misuses accumulate, leading to intermittent electrical continuity issues in the cable. This can be tough to troubleshoot because the effects are often sporadic, making it hard to pinpoint the problem.

Insulation Damage:

Think of this as the cable’s protective shield getting compromised. When the electrical insulation around each cable is damaged, it can cause short-circuiting between wires. This isn’t just a risk to your robot’s operation – it’s a safety hazard.

Corkscrewing:

Corkscrewing is another major issue. It’s when the entire cable gets twisted and deformed. This affects cables constructed in layers more than bundled cables and can severely restrict the robot’s movement.

Jacket Abrasion:

Jacket abrasion is the wear and tear on the cable’s outer layer. This happens due to constant rubbing against other surfaces or parts of the robot. Over time, this abrasion can expose the inner wires, leading to shorts and malfunctions.

Kinking:

Kinking occurs when the cable is bent too sharply or frequently, leading to permanent deformations. These kinks can disrupt the flow of electricity or signals within the cable.

External Damage:

This is caused by environmental factors like heat, chemicals, or sharp objects coming into contact with the cables. Such damage can deteriorate the cables’ effectiveness and lifespan.

Being aware of these common cable failures is crucial. You need to regularly inspect and maintain your robot’s cables to prevent these issues from arising. Remember, a little bit of preventive maintenance can save you a lot of downtime and headaches in the long run.

3 Best Practices in Robotic Cable Management:

You know the importance of keeping your robot’s cables in check, but how do you ensure they stay that way? It’s all about adopting an integrated approach.

1. Take a Segmented Approach to Cable Management:

The more you add cables, the more complex it becomes to maintain your cable system.

By segmenting your robot’s cabling, you’re setting up a more efficient system that’s easier to maintain and troubleshoot. Think of it as organizing your robot’s cabling into manageable parts :

First, identify the three key segments of your six-axis robot: the sixth to third axis, third to second, and second to first. This isn’t just splitting the robot into parts; it’s about understanding the unique movement and stress points in each segment. The idea here is to manage the cables according to the specific needs of each section, which helps in reducing stress on the cables.

For each segment, consider the range of motion and potential stress points. For instance, the sixth to third axis might experience more twisting movements, while the lower segments might have more linear movements. Based on this, you’ll want to apply different cable management techniques.

Use strain relief mechanisms for each segment. These could be tie wrap plates or clamps, ensuring that cables are not pulled or stressed beyond their capacity. Remember to leave service loops – extra lengths of cable that provide flexibility and prevent tension. This extra slack is crucial, especially when the robot is moving through extreme ranges of motion.

Finally, consider installing junction boxes at the end of each segment. These act as checkpoints, making it easier for you to maintain, troubleshoot, and replace cables if necessary. They’re like the pit stops in your robot’s cabling system, ensuring everything stays connected and runs smoothly.

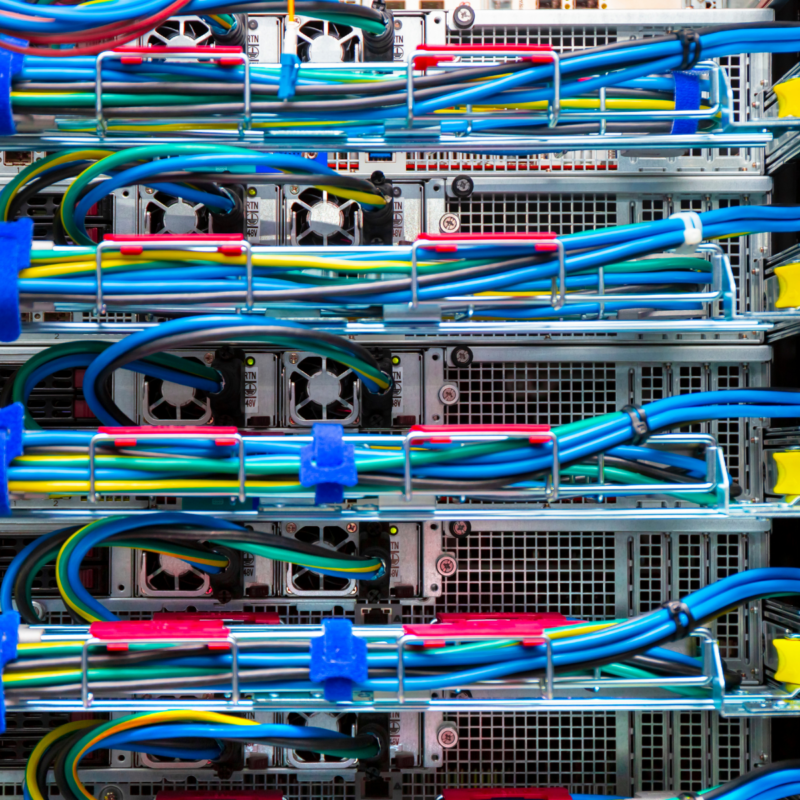

2. Leverage a Robotic Cable Carrier System:

A robotic cable carrier system is designed to keep your cables organized and out of harm’s way, ensuring they move in sync with the robot’s motions. This reduces the risk of tangling, snagging, or getting caught on external objects – all common causes of cable wear and tear.

But it’s not just about protection; it’s also about flexibility. A good carrier system allows easy addition or removal of cables. This is especially handy when you need to make quick changes or repairs, saving you time and reducing downtime. Plus, these systems often come with strain relief options, extending the service life of your cables by reducing stress on them during movement.

3. Adopt the “Less is More” Approach:

On a production floor, it’s common to use lengthy, heavy cable packages or to bind them excessively with dress packs, cable ties, or even duct tape. While these might seem like robust solutions, they can be counterproductive.

These methods often lead to cable stress, causing problems like corkscrewing and faster wear and tear. Instead, a streamlined approach, where cables are given just enough support and freedom, is key.

How do you apply this?

Start by using minimal dress packs and ensuring that cables have the right amount of strain relief. This means providing enough slack for the cables to move with the robot’s motion, but not so much that they become tangled or snagged. Service loops are your friend here, as they allow some flexibility without putting stress on the cables.

Another aspect of this approach is breaking down cable management into manageable sections, as mentioned earlier. This segmentation reduces the overall bulk and complexity of the cable setup, making it easier to manage and less prone to failure.

Remember, the goal is not to strip down your cable management to the bare minimum, but to optimize it for efficiency and longevity. It’s about smart management, not minimal management.

What are Good Cable Management Options?

There are many cable management options that not only protect your cables but also complement your robot’s functionality. Here are the 3 main types :

Flexible Tubing:

Think of this as the all-rounder in cable protection. It’s robust, versatile, and comes in various sizes and styles to suit your robot’s needs. Its key strength lies in its superior tear resistance at connection points, offering a long service life, even under the stress of reverse-bend cycles.

However, it’s not without limitations. Flexible tubing provides minimal torsion resistance and can stretch as the robot moves, which might stress the cables. Moreover, tooling interference is a risk due to the lack of a controlled movement path.

Enclosed Dress Packs:

These are like the heavy-duty armor for your cables, using corrugated tubing within a reinforced housing for extra protection. While they’re great for minimizing catch and pinch points, there’s a downside. Cable maintenance becomes a challenge due to the fully enclosed housing. Plus, if the robot’s programming or movements change, these packs might not adapt well, potentially exceeding the maximum bend radius of the cables.

Robotic Cable Carrier Systems:

Robotic cable carrier systems are tailored to the dynamic world of robotics. They offer strain relief options to extend cable life and easy cable addition or removal. The defined bend radius also protects cables from overstretching. They’re especially useful in tight spaces or for robots with multiple-tool applications.

The caveat? They may not be the best fit for environments with heavy loads or high-concentration chemicals.

When choosing a cable system option, consider the following:

- Range of Motion Compatibility: Ensure the system can accommodate the full range of motion of your robot. You don’t want a system that restricts movement or is too rigid.

- Environment Suitability: If your robot operates in harsh environments, look for carriers that can withstand those conditions, whether it’s high temperatures, abrasive materials, or corrosive substances.

- Load Capacity and Size: The system should be able to handle the weight and size of your cables without being too bulky or heavy.

- Ease of Maintenance: Opt for a system that allows for easy inspection, maintenance, and replacement of cables. This will save you a lot of headaches in the long run.

Conclusion:

You’ve learned about the types of cables, common failures, best practices, and the importance of adopting a ‘less is more’ philosophy. Now, it’s time to put this knowledge into action.

But why stop here? To truly optimize your manufacturing line, you need the right tools and insights. This is where our product reviewing platform comes into play. Dive into a world of comprehensive reviews and expert insights on the latest in robotic technology. Whether you’re looking for the best cable management solutions or the latest robotic innovations, we’ve got you covered.