ABB OmniVance™ Collaborative Arc Welding Cell Pricing & Product Details

Ranked Nr. 32 of 61 Turnkey Robot Solutions

OmniVance™ Collaborative Arc Welding Cell Overview

What is OmniVance™ Collaborative Arc Welding Cell?

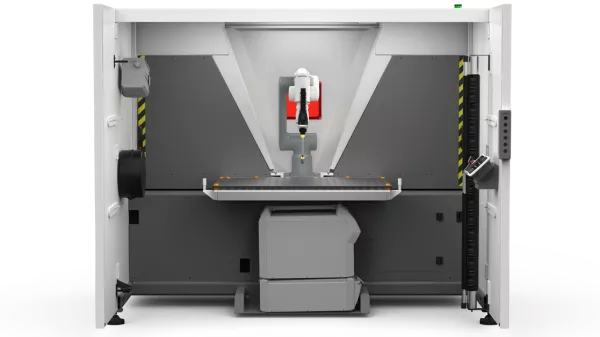

The ABB OmniVance™ Collaborative Arc Welding Cell is a turnkey solution for automating arc welding processes, designed to be accessible even to users without robotics programming experience. Pre-tested and fully integrated, this CE-certified cell includes a GoFa™ CRB 15000 collaborative robot, welding equipment, and ABB's ArcWare application software. Its standout feature is the Easy Teach Device, enabling users to program welding sequences quickly without coding expertise, reducing programming time by up to 70%.

This system combines high precision with industrial-grade software to deliver consistent weld quality, making it ideal for high-mix, low-volume production environments. Its flexibility allows operators to reprogram the cell easily for diverse welding tasks, addressing the needs of industries like manufacturing, automotive, and construction equipment. By automating simple welds, it enables manual welders to focus on complex or high-value work, boosting overall workforce efficiency.

Key elements of the OmniVance Collaborative Arc Welding Cell include a cobot-mounted Easy Teach Device, a safety fence, and a complete welding package comprising a torch, table, wire feeder, and power source. The cell offers an ideal solution for organizations aiming to address skilled labor shortages while enhancing productivity and maintaining high safety standards.

What applications is OmniVance™ Collaborative Arc Welding Cell product best for?

- Automotive Industry: The OmniVance Collaborative Arc Welding Cell is ideal for welding components such as exhaust systems, frames, and brackets with precision and consistency, catering to the high-mix, low-volume production demands of automotive manufacturers.

- Industrial Equipment Manufacturing: Used for welding parts like conveyor systems, structural frames, and custom machinery, the cell’s reprogrammable design supports diverse welding tasks and rapid production changes.

- Construction Equipment: Perfect for welding heavy-duty components such as excavator arms and loaders, the system ensures robust welds with its industrial-grade software and high-precision cobot capabilities.

- Metal Fabrication Shops: Suitable for small-scale custom welding jobs and prototyping, enabling efficient automation of simple yet repetitive tasks while maintaining flexibility for varied projects.