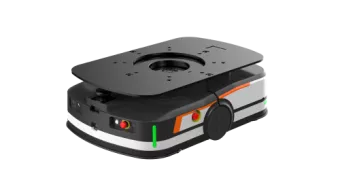

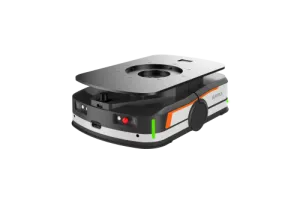

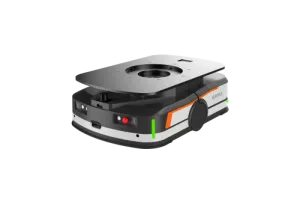

AGILOX ODM Specifications

Ranked Nr. 132 of 183 Mobile Robots

The AGILOX ODM is an omnidirectional dolly mover designed for intelligent transportation of small load carriers. It is ideal for lifting medium-heavy small load carriers, with a maximum lifting weight of 300 kg and a maximum lifting height of 250 mm.

The AGILOX ODM features an omnidirectional driving system that provides the highest flexibility in movement. It enables standardized forward and backward movements, as well as parallel, diagonal, and rotary movements around the center of the vehicle. This unrestricted freedom of movement is made possible by the rotating driving units.

Safety is a top priority with the AGILOX ODM. The vehicle can navigate precisely through its environment with safety laser scanners and optional Obstacle Avoidance. Various light points on the ground serve as safety features to indicate when an AGILOX is about to approach an obstacle.

The AGILOX ODM is compact in size, with dimensions of 1,100 x 400 x 1,235 mm. It has a dead weight of 160 kg and a turning circle of 1,600 mm. The minimum aisle width required for the vehicle is 900 mm.

Overall, the AGILOX ODM is a high-performing, small AMR designed for transporting small load carriers with ease and safety. Its compact size and omnidirectional driving system make it an ideal solution for applications with limited space or tight corners. With a charging time of only 11 minutes, the AGILOX ODM is a reliable and efficient addition to any logistics operation.

| Industry |

|

| Application |

|

| Product mass | 160 kg |

| Payload | 300 kg |

| Type of Technology |

|

| Speed | 1.4 m/s |