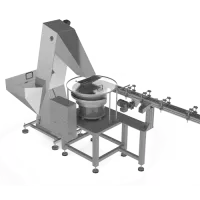

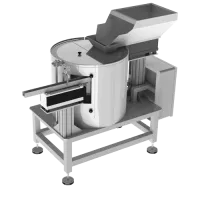

Ars Automation FlexiBowl 650® Specifications

Ranked Nr. 78 of 98 Robot Accessories

FlexiBowl® 650C/CC is a flexible feeder able to feed products of any geometry, surface and material. It is compatible with all industrial robots and vision systems. One FlexiBowl® can feed entire ranges of parts measuring 10 to 110 mm and weighing up to 170 g, replacing the need for the numerous units used in conventional systems.

| Type |

|

| Type | Flexible parts feeder |