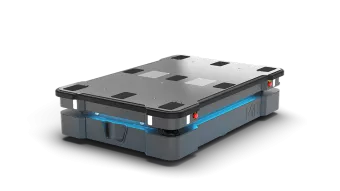

Beewatec BARY PXS-500 Specifications

Ranked Nr. 119 of 183 Mobile Robots

Our BARY PXS-500 could soon be your new colleague in intralogistics. It drives under racking systems or material handling trolleys, lifts them and transports them from A to B. Our AMR thus ensures an automated flow of goods and reduces walking distances and costs in your production and logistics.

Our BARY PXS-500 can be used flexibly, for example for

- In-plant transport and material distribution from the goods receiving department

- automated material supply to workstations

100%

Process and planning stability through automated material transport - just in time.

0

Downtime within processes or of machines through a demand- and process-oriented supply.

24/7

Availability of the PXS-500, made possible by independent charging with BEECharge.

Controlling BARY PXS-500

With just a few steps an emerging material demand becomes a sucessfully completed transportation job - fully automated.

Step 1

With the BARY PXS-500, everything starts with a material demand. This can be triggered either manually (e.g. by pressing a push button) or automatically (e.g. by triggering an optical sensor).

Step 2

This information is transmitted either wired (via LAN) or wireless (via Wifi/WLAN) to the Order Management System (OMS), which independently generates a transport job ("Bring X from A to B") based on the signal input.

Step 3

The transport job of the OMS is then transferred to the fleet management system. This manages and prioritises the transport jobs independently (manual intervention possible), plans the robot's routes and sends a transport job via WLAN to the autonomous mobile robot (AMR) in the field.

If required, internal systems such as WMS/ERP systems can be connected to the fleet management software via a standardised or individual interface / middleware.

Step 4

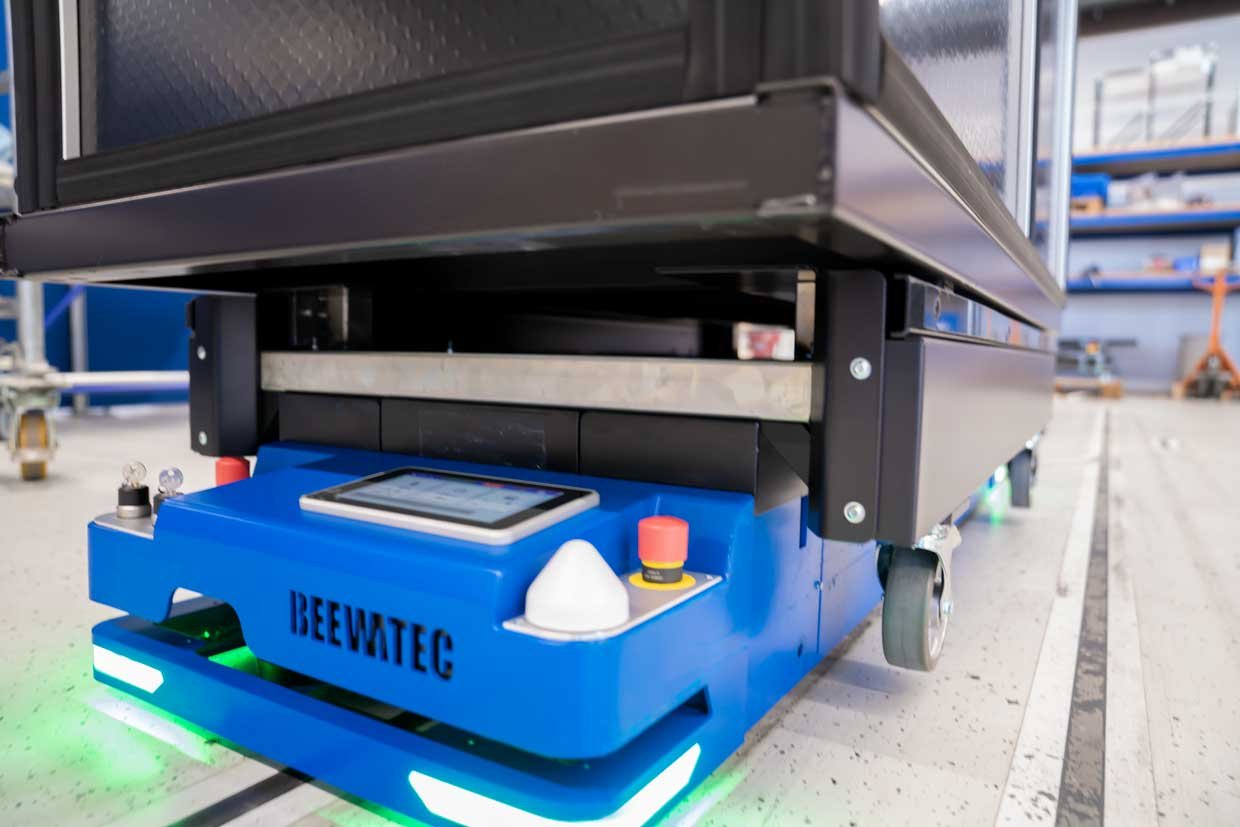

BARY PXS-500 receives the transport job from the fleet management system, picks up the material handling trolley for example at the specified location, transports it from A to B, puts down the trolley and then reports the succesful completion of the job back to the fleet management system.

This is how the robot navigates - freely and autonomously.

Each AMR from BeeWaTec moves freely and autonomously in its environment with the help of sophisticated algorithms.

In doing so, the AMR calculates the path of least resistance in real time based on the environmental data, depending on distances, obstacles, people or restricted zones (e.g. shelves or work areas). This ensures maximum efficiency in the allocation of your goods at all times.

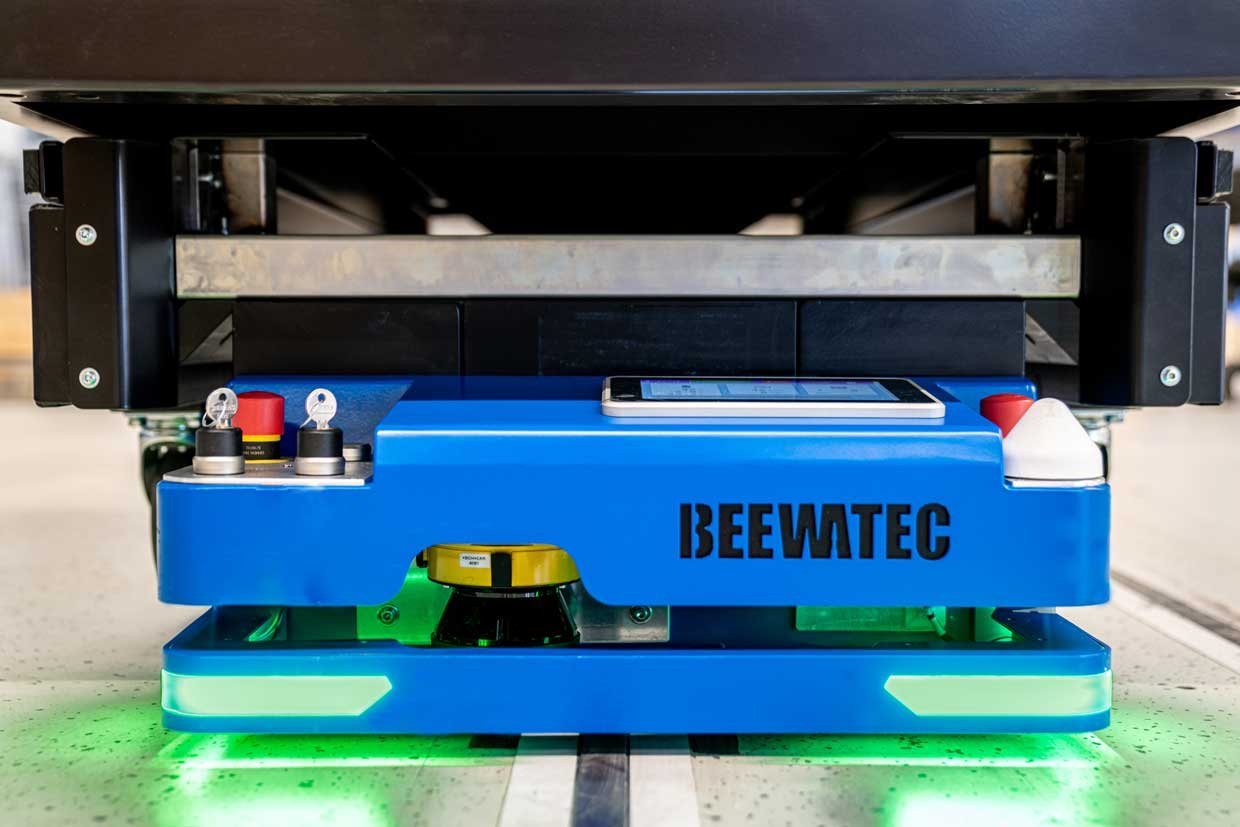

The integrated safety laser scanner is used in parallel as a person protection device as well as for intelligent navigation and offers additional safety for your employees.

Our AMRs move freely through their environment with a positioning accuracy of +/- 10mm. For an even higher positioning accuracy of up to +/- 5 mm, additional navigation modes can be used if required, between which the AMR can automatically switch during operation (for example directly in front of a transfer station).

BeeWaTec offers a total of four different navigation types, which have different advantages and disadvantages depending on the operating environment, the system requirements and other aspects.

Material is being handed over.

The BARY PXS-500 manoeuvres underneath structures (e.g. shelves) and lifts them via an integrated lifting unit. After the transport, the autonomous mobile robot places the respective structure at a defined location and carries out the next transport job.

We do not leave you on your own with our robot, but offer you the suitable solution with our tube plug-in system, whereby any type of transfer point can be realised.

| Payload | 500 kg |

| Dimensions | |

| Operating time | up to 8 hours |

| Accuracy | 0 mm |