Brovind Vibrating drive units for circular feeders Pricing & Product Details

Ranked Nr. 100 of 98 Robot Accessories

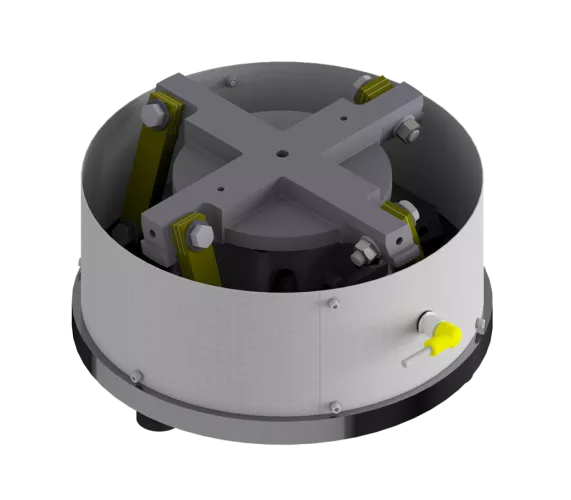

Vibrating drive units for circular feeders Overview

What is Vibrating drive units for circular feeders?

Brovind's vibrating drive units are designed to generate the necessary vibration required for feeding and orienting parts inside prepared bowls. These units are essential components of circular feeders, which are widely used in various manufacturing and assembly processes to automate the feeding and orientation of small parts.

The vibrating drive units manufactured by Brovind are powered by an electromagnet and are controlled by an electronic controller. The controller allows for precise adjustments to the vibration frequency and intensity, ensuring that the parts are fed and oriented accurately and reliably. Additionally, these units can be fitted with a sensor, which allows for real-time monitoring and offsetting of vibration parameters, further enhancing their accuracy and reliability.

The standard power supply for Brovind's vibrating drive units is single-phase 230V, 50 Hz, which is compatible with most industrial power systems. However, these units can also be supplied with different voltages and frequencies to meet specific requirements.

One of the main advantages of Brovind's vibrating drive units is their versatility. They can be easily integrated into existing manufacturing and assembly lines and are compatible with a wide range of parts and feeders. They are also designed to be low-maintenance, with a long service life, ensuring maximum uptime and productivity.

In conclusion, Brovind's vibrating drive units are an essential component of circular feeders, providing reliable and accurate vibration necessary for feeding and orienting small parts. With their electronic controllers, sensor options, and versatility, these units offer a cost-effective and efficient solution for automating manufacturing and assembly processes.

What applications is Vibrating drive units for circular feeders product best for?

Brovind's vibrating drive units are suitable for a wide range of applications in which small parts need to be fed and oriented accurately and reliably. Some of the most common applications include:

1. Automotive assembly: Brovind's vibrating drive units are commonly used in automotive assembly lines to feed and orient small parts such as screws, bolts, and nuts.

2. Electronics manufacturing: These units are also used in electronics manufacturing processes to feed and orient small electronic components such as capacitors, resistors, and connectors.

3. Medical device assembly: Brovind's vibrating drive units are often used in the production of medical devices such as syringes, inhalers, and surgical instruments, where precise feeding and orientation of small parts is critical.

4. Packaging and labeling: These units can also be used in packaging and labeling processes to feed and orient small items such as pills, candy, or other small products.

5. Food and beverage processing: Brovind's vibrating drive units can also be used in food and beverage processing to feed and orient small ingredients such as spices, nuts, and grains.

In summary, Brovind's vibrating drive units are ideal for any application that requires the precise feeding and orientation of small parts, making them a versatile solution for many different industries.

What are the specifications of Vibrating drive units for circular feeders?

| Type |

|