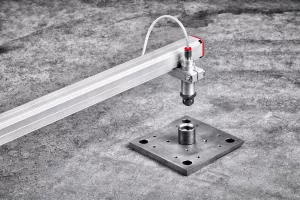

Camozzi Group Three finger gripper-125mm bore Specifications

Ranked Nr. 130 of 235 Grippers

| Gripper mass | 2.22 kg |

| Operation type |

|

| Number of fingers |

|

| Gripper mass | kg |

| Energy source |

|

| Protection (IP) | IP40 |

| Extra info | Robust and light 3 self-centering jaws Fixing from the top and from below Supply on the side or on the bottom (even without using tubes) Double position detection Variants available: for use in ATEX zones and for high temperatures In compliance with ROHS directive High positioning repeatability High resistance and reliability to external loads thanks to T-guide Free from Copper, PTFE and Silicone |

Three finger gripper-125mm bore Downloads

Series20 CGZT20320 Jaw20 Grippers20with20 T Guide

You need to

register

to download this file.