Dematic Pallet Mover Specifications

Ranked Nr. 175 of 183 Mobile Robots

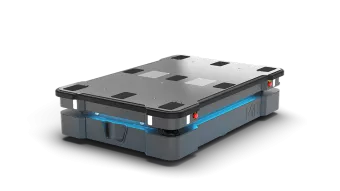

The Dematic Pallet Mover is an autonomous mobile robot (AMR) designed to provide flexible transportation within a warehouse environment, offering an alternative to traditional conveyor systems. These robots are capable of efficiently moving goods and materials throughout the warehouse while safely navigating around people, equipment, and inventory.

One standout feature of the Dematic Pallet Mover is its ability to optimize space utilization within the warehouse. By eliminating the need for fixed conveyors, these AMRs open up expanses of space that are typically consumed by conveyor systems. This flexibility allows for more efficient use of warehouse floor space and enables easy reconfiguration of the layout as needed.

The Dematic Pallet Mover AMR comes in different models to cater to various requirements. The AMR D900 model has a height of 500 mm and a payload capacity of 900 kg, while the AMR D1300 model has a height of 700 mm and a payload capacity of 1300 kg. This range of models ensures that there is an option suitable for different load sizes and operational needs.

In terms of applications, the Dematic Pallet Mover is well-suited for tasks such as moving pallets between functional areas within the warehouse, line-side supply and delivery, as well as small and large assembly platforms. Its versatility allows it to adapt to various scenarios and contribute to the smooth flow of materials and goods within the warehouse environment.

The Dematic Pallet Mover is also designed to integrate with a wide variety of products and solutions. It can seamlessly work with Dematic's Micro-Fulfillment solutions, which automate order fulfillment in a compact footprint that can fit within a retail store or small warehouse. Additionally, the Pallet Mover can be integrated with conveyor systems for processing large quantities of inventory, AutoStoreTM storage and fulfillment systems for scalable robotic storage and piece picking, and mixed-case fulfillment solutions for transforming SKU pure pallets into mixed case pallets.

Furthermore, the Dematic Pallet Mover is compatible with AGVs (Automated Guided Vehicles), offering a modern and cost-effective solution for distribution and production operations to increase throughput without the need for additional labor, physical space, or bulky equipment. This compatibility with AGVs enhances the overall automation capabilities of the warehouse and streamlines material handling processes.

While specific details about extreme temperature tolerance or software system compatibility are not mentioned in the provided information, it's worth noting that Dematic is a leading provider of industrial automation solutions and has a reputation for engineering systems that can operate reliably in challenging environments. They also offer a range of software solutions and integration capabilities to ensure seamless communication and coordination between their AMRs and other warehouse automation systems.

| Industry |

|

| Application |

|

| Type of Technology |

|

| Payload | 1300 kg |