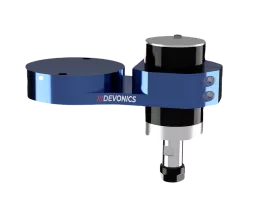

Devonics Automatic Tool Changer Specifications

Ranked Nr. 8 of 116 End of Arm Tools

The Devonics Automatic Tool Changer introduces a magnetic mechanism designed to streamline the process of switching between tools or end-effectors in robotic applications. This system supports a 20 lbs payload, facilitating the handling of a diverse range of tools without compromising on performance. One of its most notable features is the rapid tool switching capability, enabling load and unload operations in approximately 1 second. This efficiency is crucial in high-paced manufacturing environments, where time savings directly translate to increased productivity and reduced downtime.

Safety and reliability are paramount in the design of the Devonics Automatic Tool Changer. The system ensures that tools remain securely attached even in the event of power loss or emergency stop (E-STOP) activation. This safety feature is particularly important in preventing accidents and damage to both the tools and the workpiece, thereby maintaining operational integrity and minimizing the risk of unexpected costs due to equipment damage.

Designed for seamless integration with UFactory Xarm series robots, the package includes an automatic tool changer master, which is fixed to the robot arm, and two tool holders, which accommodate different end-effectors or tools per operation. This plug-and-play setup underscores the system's ease of installation and compatibility, making it an excellent choice for users looking to enhance the versatility and efficiency of their robotic operations without significant setup complexities. The Devonics Automatic Tool Changer, with its patent-pending technology, represents a significant advancement in robotic tool changing, offering a blend of speed, safety, and versatility for a wide range of industrial applications.

| Application |

|

| Industry |

|

| Type |

|