fruitcore robotics horstCUBE plug & play part separation Pricing & Product Details

Ranked Nr. 16 of 61 Turnkey Robot Solutions

horstCUBE plug & play part separation Pricing

Choose your model

Price indication:horstCUBE plug & play part separation Overview

What is horstCUBE plug & play part separation?

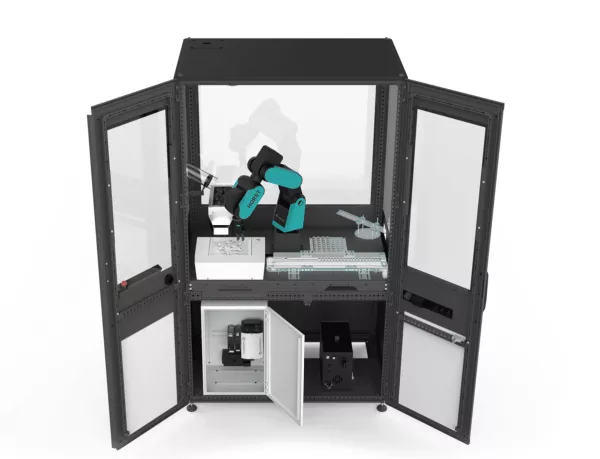

The fruitcore robotics horstCUBE plug & play part separation system provides an integrated solution for separating bulk materials using advanced camera recognition and an automated part separator. It features a standard configuration that includes the horstCUBE robot platform, a Digital Robot HORST600, a VarioShaker 270 bulk material separator, a 5L vibration hopper, a camera, and an electrical 2-jaw parallel gripper. This setup allows for efficient separation and handling of parts in various manufacturing processes.

The system is designed to accommodate additional process steps such as output, inspection, sorting, or labeling. It includes comprehensive support for setup, including assembly, configuration, and program creation, with customization options available to meet specific operational requirements. This flexibility ensures the system can be tailored to diverse industry needs.

The horstCUBE plug & play part separation is characterized by its easy configuration, rapid implementation, and space-saving design. It operates without the need for an additional PLC, simplifying integration into existing processes. Its cost-effective pricing framework and quick delivery of components make it suitable for various industrial applications where bulk material handling and process integration are required.

What applications is horstCUBE plug & play part separation product best for?

- Automotive Manufacturing: The horstCUBE part separation system efficiently handles bulk components like engine parts and fasteners, automating sorting and separation tasks in automotive assembly lines.

- Electronics Assembly: It separates and handles bulk electronic components, such as circuit board parts and connectors, facilitating smooth processing and assembly in electronics production.

- Packaging and Labeling: The system supports bulk material handling for packaging and labeling applications, enabling automatic sorting and preparation of products for packaging lines.

- Consumer Goods Production: It is used in the separation and sorting of bulk items in consumer goods manufacturing, such as plastic parts and packaging materials, improving efficiency and process flow.