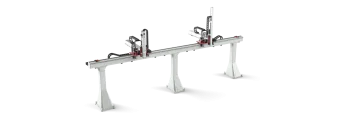

Güdel 3-Axis Type CP Specifications

Ranked Nr. 24 of 36 Cartesian (Gantry) Robots

Space-saving 3-axis gantry with various applications

The Güdel CP cantilever gantry is an impressive, highly flexible 3-axis linear robot. It is perfectly suited for dynamic machine loading and palletizing operations with high payloads.

Due to the linear axis kinematics, positions can be approached from above. Also large work areas can be addressed with no floor intrusions, and the cantilever axis allows for a 3D working envelope. The CP saves a lot of space because it does not require extra support legs, and this creates unique opportunities in layout planning.

The CP is characterized with high payload range and consistent high precision.

Our gantry concept enables the legs to be flexibly positioned on the gantry beam

This is a huge advantage during the planning phase as the precise dimensions of the processes or machines to be automated are often only known at a relatively late stage.This flexibility also allows the system to be modified at a resonable cost if adjustments to the production processes are desired at a later date.The beams are available in standard lengths. They are equipped on both sides with exact joining elements, making almost any desired total length possible. Our flexible system even makes retrofitting your production line for new processes economical.

3-Axis Type CP Downloads

Factsheet Robotics CP EN

You need to

register

to download this file.