Jungheinrich AG EZS 350a Alternatives & Competitors

Ranked Nr. 156 of 183 Mobile Robots

Top 10 EZS 350a Alternatives

- WObit MOBOT® AGV CubeRunner2

- GESSbot GB350

- Loading Robots by DF Nalon Backbot

- Mobile Industrial Robots MiR1350

WObit MOBOT® AGV CubeRunner2

Payload 200kg | Product mass 220kgMOBOT® AGV CubeRunner2 (Automated Guided Vehicle) is a mobile robot for automatic transport of goods. The robot autonomously attaches trailers using two retractable pins. Due to its compact design CubeRunner is adjusted to tow different types of trailers, e.g. with rollers. It fits perfectly for applications in automotive, FMCG, and in all general manufacturing production applications.

Navigation MOBOT® AGV CubeRunner2 (004) operates using a natural and intelligent navigation system LMS (laser terrain mapping system) and along a color line with a vision system. Also, the information is marked with QR codes.

Design In standard the MOBOT® AGV CubeRunner2 is equipped with a symmetric drive system, double positioning system, and two safety laser scanners which allows two-way movement without turning back.

Charging option The robot is equipped with 2 batteries in cassette, which enable quick swapping. it can also be charged using wire charging station, optionally there is a possibility of using an automatic charging station. Speed The maximum speed of this model is up to 3 km/h.

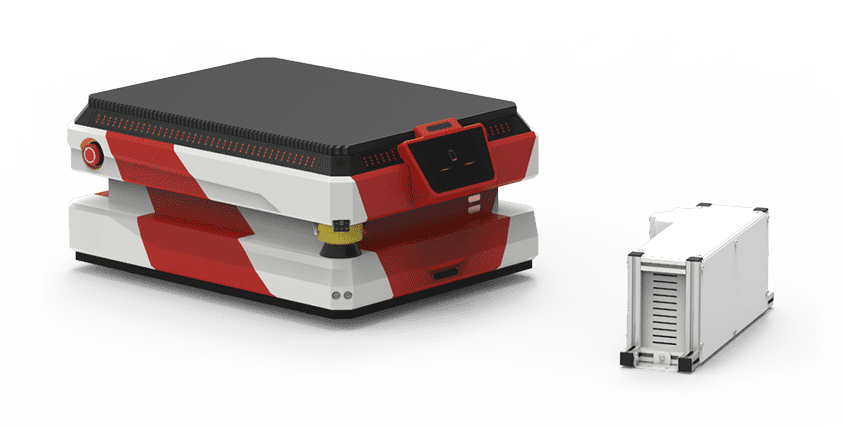

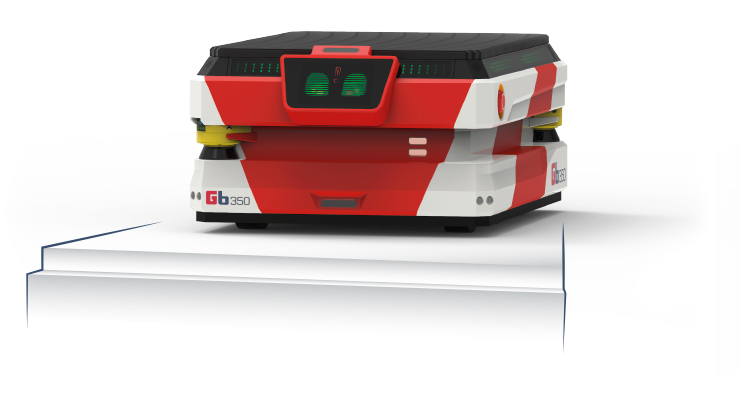

GESSbot GB350

AGV | Payload 350kg | Product mass 150kgThe Gb350 is an automatically guided vehicle (AGV) for quick and cost-efficient automation of your internal transport processes. The Gb350 has a payload of 350kg.

No expensive extras and auxiliary systems, such as magnetic tracks, induction loops or additional safety systems are required. The AGV easily integrates into your existing production and logistics structures.

Autonomous movement

The robot moves autonomously within your company. Thanks to the fusion of various sensor systems, the Gb350 maintains an overview of everything within a radius of 20 m.

Using the Social Navigation System (SNS), it reacts to dynamic changes and always choses the optimum route. People and machines work in perfect harmony thanks to this collaborative behaviour.

GESSbot Charge System

The charging process is fully automated

Fall protection thanks to step and cavity recognition

Overload-proof and with integrated scale

Great audio-visual features

Thanks to the GESSMANN Blackpanel System and an integrated sound module, we underline the actions and movements of the robot visually and acoustically. The latest energy-saving LED technology is used to do this.

Easy to operate

User-friendly, configurable interface

Structures with industry interfaces

Standard structures and customer-specific solutions can be provided. Those are connected directly to the Gb350 and thus form a unit.

Mobile Industrial Robots MiR1350

AMR | Payload 1350kg | Product mass 247kgThe Mobile Industrial Robots MiR1350 is a highly capable autonomous mobile robot designed for heavy-duty material handling. It supports payloads up to 1350 kg and has a towing capacity of 6,000 kg, making it suitable for transporting very heavy items across industrial environments. Its robust design accommodates significant load requirements, enhancing efficiency in handling and logistics operations.

Safety is a key feature of the MiR1350, which meets high standards such as EN ISO 13849-1. It is equipped with advanced safety technologies including 3D cameras, laser scanners, and various sensors that ensure obstacle detection and avoidance. This comprehensive safety system allows it to operate safely in complex and dynamic environments.

The MiR1350 is versatile and can be customized with a range of accessories such as conveyors, lifts, and racks to meet diverse material handling needs. It integrates seamlessly with warehouse management systems (WMS) and enterprise resource planning (ERP) systems, and can operate in both automated and manual modes, providing flexibility in complex industrial settings.