Jungheinrich AG EZS 350a Specifications

Ranked Nr. 156 of 183 Mobile Robots

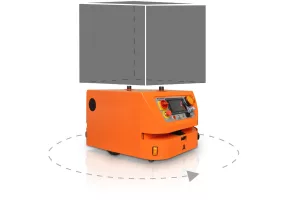

The Jungheinrich EZS 350a is a versatile and robust automated tow tractor designed to enhance production environments. It excels in effectively pulling trailers weighing up to 5,000 kg as part of a tow train system. Developed from their proven standard truck, the EZS 350a is specifically optimized for warehouse work and transport processes, making it a reliable and efficient solution.

The standout feature of the EZS 350a is its precision navigation technology. The truck utilizes laser navigation, detecting reflectors installed along the travel route. This advanced navigation system ensures accurate and reliable movement throughout the facility, enabling smooth and efficient towing operations. This precision is particularly crucial when towing heavy trailers, ensuring safety and reducing the risk of accidents or damage to goods.

Safety is a paramount concern in industrial automation, and the EZS 350a is equipped with an extensive safety system. This system ensures the protection of both the vehicle and the people working in the vicinity. With its integrated safety features, the tow tractor can operate in mixed environments alongside manual trucks and pedestrians. This versatility allows for seamless integration into existing structures or utilization as a standalone solution, providing increased efficiency in diverse production facilities.

The EZS 350a is equipped with a 24-V 3-phase AC motor, which offers high performance while maintaining low energy consumption. This combination of power and energy efficiency ensures optimal performance during towing operations while minimizing operating costs. The motor provides consistent and reliable power delivery, allowing the tow tractor to handle heavy loads with ease.

In terms of specialized specifications, the provided information does not explicitly mention tolerance for extreme temperatures or compatibility with specific software systems. However, it's worth noting that Jungheinrich products are known for their high-quality engineering and customization options. Therefore, it is possible that the EZS 350a may offer features such as tolerance for extreme temperatures, making it suitable for use in challenging environments like cold storage facilities or high-temperature manufacturing areas.

Additionally, the EZS 350a can be integrated into existing IT structures, allowing for seamless communication and coordination with other automated equipment or warehouse management systems. This compatibility enhances overall workflow efficiency and enables the tow tractor to be seamlessly incorporated into existing automation setups.

In summary, the Jungheinrich EZS 350a automated tow tractor is a versatile and robust solution for enhancing production environments. Its standout features include precision navigation technology, an extensive safety system, and a powerful yet energy-efficient motor. The ability to operate in mixed environments, along with its compatibility with existing structures or standalone use, provides flexibility in various production facilities. While not explicitly mentioned, it's possible that the EZS 350a offers specialized specifications such as tolerance for extreme temperatures and compatibility with specific software systems, further enhancing its capabilities in industrial automation.

| Payload | 5000 kg |

| Industry |

|

| Application |

|

| Type of Technology |

|