Karlsruher Institut für Technologie ARMAR-6 Pricing & Product Details

Ranked Nr. 1 of 39 Humanoid Robot

ARMAR-6 Overview

What is ARMAR-6?

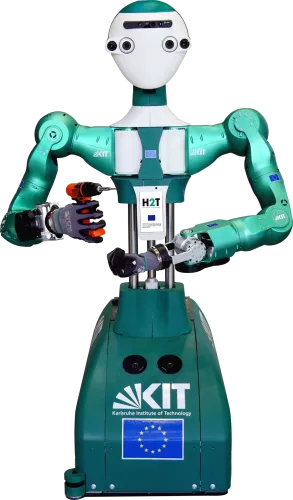

ARMAR-6, developed by the Karlsruhe Institute of Technology (KIT), is a humanoid robot designed for industrial environments, focusing on collaborative assistance. It features a humanoid form that allows it to use standard human tools, such as power drills and hammers, making it highly adaptable in maintenance and support tasks. Equipped with artificial intelligence, ARMAR-6 can autonomously recognize when human assistance is needed and proactively provide support, enhancing efficiency in dynamic industrial settings.

The robot operates with four onboard computers that power its control, image processing, and interaction algorithms. Its software architecture, built on the ArmarX framework, supports machine learning and AI functionalities, enabling it to perform tasks with precision and adapt to unanticipated situations. ARMAR-6’s arms include advanced actuators with slip rings, allowing for continuous joint rotation and force-controlled motions, making it capable of handling complex tasks requiring dexterity and precision.

ARMAR-6 is specifically designed for industrial applications, such as maintenance in factories, assembly line assistance, and tool handling in environments where human-robot collaboration is essential. It improves operational efficiency by reducing downtime and assisting workers with repetitive or hazardous tasks. The robot's autonomous capabilities and battery-powered operation allow it to function independently in large-scale industrial settings without the need for constant human supervision.

What applications is ARMAR-6 product best for?

- Industrial Maintenance: ARMAR-6 excels in industrial environments by autonomously performing maintenance tasks such as equipment inspections, tool handling, and predictive maintenance. Its AI capabilities enable proactive assistance to human workers.

- Manufacturing Support: ARMAR-6 assists in complex assembly lines by using human tools like drills and hammers, enabling efficient and precise operations while adapting to unexpected scenarios with its advanced control algorithms.

- Collaborative Workspaces: The robot enhances human-robot collaboration in manufacturing facilities by recognizing worker needs and offering real-time assistance, optimizing workflow and improving workplace safety.

- Logistics Operations: ARMAR-6 can support logistics by autonomously identifying, handling, and transporting objects in warehouses, streamlining operations with its advanced perception and manipulation capabilities.

- Research and Development: ARMAR-6 serves as a versatile platform for robotics research, allowing institutions to study AI integration, human-robot interaction, and adaptive behavior in dynamic industrial environments.