Liberty Reach V-Guide Specifications

Ranked Nr. 123 of 97 3D Vision Systems

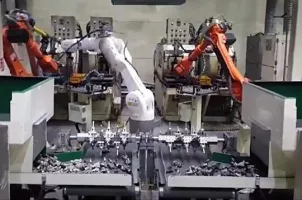

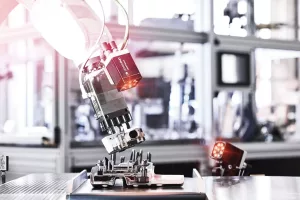

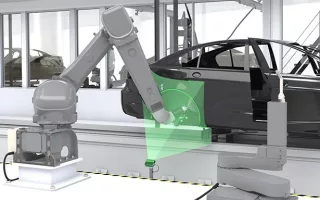

The Liberty Reach V-Guide is a versatile robot-mounted vision system that employs true 3D vision sensors to swiftly determine position and rotation offsets in under one second. Its standout features include exceptional speed, providing true 3D offsets in less than a second, and its robustness, as it can reliably calculate significant part-to-part shifts and rotations. It remains dependable even amidst varying factory lighting conditions, eliminating the need for external lights, which aids in reducing faults and downtime.

Notably, the V-Guide is remarkably flexible, accommodating style additions and model changes with minimal need for extra sensors or equipment. Its design is robust and capable of withstanding typical factory conditions, with options for industrially-hardened sensor casing. Installation, operation, adjustments, and maintenance are streamlined, offering a simple and cost-effective solution. The Liberty Reach V-Guide sets itself apart as a swift, adaptable, and dependable vision system for various industrial automation applications, particularly in situations where rapid and precise adjustments are essential.

| Industry |

|

| Application |

|

| Image Type |

|