Matrox Imaging Matrox Design Assistant X Pricing & Product Details

Ranked Nr. 24 of 85 Robot Software

Matrox Design Assistant X Pricing

Choose your model

Price indication:Matrox Design Assistant X Overview

What is Matrox Design Assistant X?

Matrox Design Assistant® X1 is an integrated development environment (IDE) for Microsoft® Windows® where vision applications are created by constructing an intuitive flowchart instead of writing traditional program code. In addition to building a flowchart, the IDE enables users to design a graphical web-based operator interface for the application.

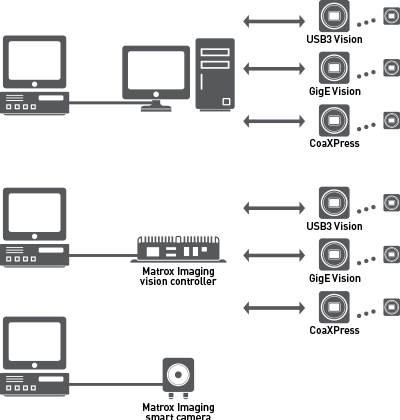

Matrox Design Assistant X can operate independent of hardware, allowing users to choose any computer with CoaXPress®, GigE Vision®, or USB3 Vision® cameras and get the processing power needed. Image capture from CoaXPress cameras happens with the use of a Matrox Rapixo CXP frame grabber. Matrox Design Assistant X works with multiple cameras all within the same project, or per project running concurrently and independently from one another, platform permitting. This field-proven software is also a perfect match for a Matrox Imaging vision controller or smart camera. Matrox Design Assistant X includes classification steps that categorize image content using deep learning.

This flowchart-based vision software offers the freedom to choose the ideal platform for any vision project and speeds up application development.

Matrox Design Assistant X at a glance

- Solve machine vision applications efficiently by constructing flowcharts instead of writing program code

- Choose the best platform for the job within a hardware-independent environment that supports Matrox Imaging smart cameras and vision controllers and third-party PCs with CoaXPress, GigE Vision, or USB3 Vision cameras

- Tackle machine vision applications with utmost confidence using field-proven tools for analyzing, classifying, locating, measuring, reading, and verifying

- Leverage deep learning for visual inspection through image classification and segmentation tools

- Use a single program for creating both the application logic and operator interface

- Work with multiple cameras all within the same project or per project running concurrently and independently from one another, platform permitting

- Interface to Matrox AltiZ and third-party 3D sensors to visualize, process, and analyze depth maps and point clouds

- Rely on a common underlying vision library for the same results with a Matrox Imaging smart camera, vision system, or third-party computer

- Maximize productivity with instant feedback on image analysis and processing operations

- Receive immediate, pertinent assistance through an integrated contextual guide

- Communicate actions and results to other automation and enterprise equipment via discrete Matrox I/Os, RS-232, and Ethernet (TCP/IP, CC-Link IE Field Basic, EtherNet/IP™2, Modbus®, OPC UA, and PROFINET®, and native robot interfaces)

- Test communication with a programmable logic controller (PLC) using the built-in PLC interface emulator

- Maintain control and independence through the ability to create custom flowchart steps

- Increase productivity and reduce development costs with Matrox Vision Academy online and on-premises training

- Protect against inappropriate changes with the Project Change Validator tool

Application design

Flowchart and operator interface design are done within the Matrox Design Assistant X IDE hosted on a computer running 64-bit Windows. A flowchart is put together using a step-by-step approach, where each step is taken from an existing toolbox and is configured interactively. Inputs for a subsequent step—which can be images, 3D data, or alphanumeric results—are easily linked to the outputs of a previous step. Decision-making is performed using a flow-control step, where the logical expression is described interactively. Results from analysis and processing steps are immediately displayed to permit the quick tuning of parameters. A contextual guide provides assistance for every step in the flowchart. Flowchart legibility is maintained by grouping steps into sub-flowcharts. A recipes facility enables a group of analysis and processing steps to have different configurations for neatly handling variations of objects or features of interest within the same flowchart. In addition to flowchart design, Matrox Design Assistant X enables the creation of a custom, web-based operator interface to the application through an integrated HTML visual editor. Users alter an existing template using a choice of annotations (graphics and text), inputs (edit boxes, control buttons, and image markers), and outputs (original or derived results, status indicators, and charts). A filmstrip view is also available to keep track of and navigate to previously analyzed images. The operator interface can be further customized using a third-party HTML editor.

Custom flowchart steps

Users have the ability to extend the capabilities of Matrox Design Assistant X by way of the included Custom Step software development kit (SDK). The SDK, in combination with Microsoft Visual Studio® 2019 or 2022, enables the creation of custom flowchart steps using the C# programming language. These steps can implement proprietary analysis and processing, as well as proprietary communication protocols. The SDK comes with numerous project samples to accelerate development.

Application deployment

Once development is complete, the project—with flowchart(s) and operator interface(s)—is deployed either locally or remotely. Local deployment is to the same computer or Matrox Imaging vision controller as was used for development. Remote deployment is to a different computer, including Matrox Imaging vision controllers, or a Matrox Imaging smart camera.

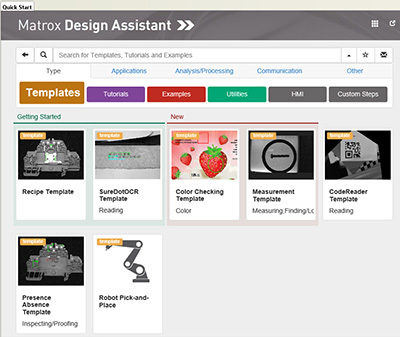

Project templates for quicker start-up

Matrox Design Assistant X includes a series of project templates and video tutorials to help new developers get up and running quickly.

These templates serve as either functional applications or application frameworks intended as a foundation for a target application. Templates also permit dynamic modifications, allowing users to tweak functionality at runtime and immediately see the outcome of any adjustments. The project templates address typical application areas, with examples for:

Barcode and 2D code reading

Measurement

Presence/absence

Recipes

Robot guidance (pick-and-place)

Dot-matrix text reading (SureDotOCR®)

Color checking

Customizable developer interface

The Matrox Design Assistant X user interface can be tailored by each developer. The workspace can be rearranged, even across multiple monitors, to suit individual preferences and further enhance productivity.

Project Change Validator

Project Change Validator is a utility employing a client-server architecture for ensuring that changes made to a deployed project are not detrimental to the functioning of that project. It provides the ability to record reference images—along with the associated inspection settings and results, for a given project.

This archived reference data is then used to validate changes made to the project. Changes are validated by running the modified project with the reference data and comparing the projects’ operation against this data. Validation is performed by the server—typically running on a separate computer—which is reachable over a network.

The Matrox Design Assistant X management portal provides access to the validation data and results. Validation requests are made on demand from the management portal, an automation controller, or an HMI panel.

Project Change Validator (view from management portal)

PLC interface emulation

While developing a project in Matrox Design Assistant X, the PLC interface emulator is used to test communication in instances when a physical one is not connected. Values can be changed and viewed dynamically to test the communication between the project and the PLC. The PLC interface emulator supports CC-Link IE Field Basic, EtherNet/IP2, MODBUS over TCP/IP, and PROFINET protocols for communication; these can be activated and controlled from the management portal.

Connect to devices and networks

Matrox Design Assistant X can capture images from any CoaXPress, GigE Vision, or USB3 Vision compliant camera. Image capture from CoaXPress cameras happens with the use of a Matrox Rapixo CXP frame grabber. For GigE Vision cameras, the exact capture time can be obtained from IEEE 1588 timestamps.

The software can communicate over Ethernet networks using the TCP/IP as well as the CC-Link IE Field Basic, EtherNet/IP2, Modbus over TCP/IP, and PROFINET protocols, enabling interaction with programmable logic/automation controllers. Its QuickComm facility provides ready-to-go communication with these controllers. Matrox Design Assistant X supports OPC UA communication for interaction with manufacturing systems and direct communication with select robot controllers for 2D vision-guided robotic applications. Supported robot-controller makes and models currently include the ABB IRC5; DENSO RC8; Epson RC420+ and RC520+; Fanuc LRMate200iC and LRMate200iD; KUKA KR C2; and Stäubli CS8, CS8C HP, and CS9 controllers.

Matrox Design Assistant X can be configured to interact with automation devices through a computer’s COM ports. Matrox Design Assistant X can also directly interact with the I/Os built into a Matrox Imaging vision controller, smart camera, and I/O card as well as the I/O available on a GigE Vision or USB3 Vision camera.

What are the specifications of Matrox Design Assistant X?

| Software type |

|