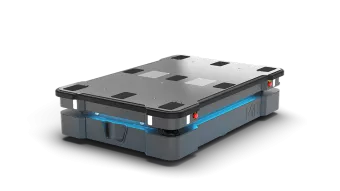

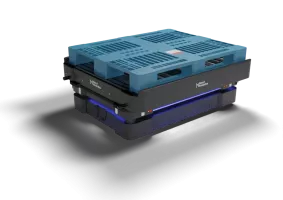

Nord Modules NORD Conveyor 1000 V4 – OTTO 1500 Specifications

Ranked Nr. 201 of 183 Mobile Robots

The NORD Conveyor 1000 V4 – OTTO 1500 is designed to enhance the operational capabilities of the OTTO 1500 autonomous mobile robot by enabling it to receive and deliver pallets efficiently. With dimensions of 1745 x 1205 x 165 mm, this conveyor can handle a maximum load of 1650 kg, making it suitable for transporting heavy payloads to production lines or packing stations. The conveyor's transport area measures 1623 x 1138 mm, providing ample space for large pallets, while its speed of 200 mm/sec ensures swift and efficient movement.

A key feature of the NORD Conveyor 1000 is its integrated technology that allows wireless communication with external roller conveyors. This capability, combined with the OTTO Standard Dock Target, enables the conveyor to dock seamlessly and autonomously transfer pallets. The system's design includes a center distance of 95.8 mm between rollers and a robust construction weighing 250 kg, ensuring durability and reliability in demanding industrial environments.

The NORD Conveyor 1000 is highly versatile and user-friendly, offering docking from both sides (run-through) and a high level of feedback through its stack-light system. It is equipped with PLC controller and servo technology for precise operation, and an optional rubber coating of the rollers can be added for enhanced grip. This solution is ideal for optimizing logistics and production processes, particularly in industries requiring the transport of US-sized pallets and other large items.

| Product mass | 250 kg |

| Industry |

|

| Application |

|

| Payload | 1650 kg |

| Speed | 0.02 m/s |

| Type of Technology |

|