Nord Modules PM800-MiR Specifications

Ranked Nr. 201 of 183 Mobile Robots

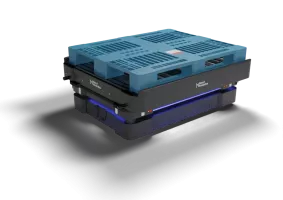

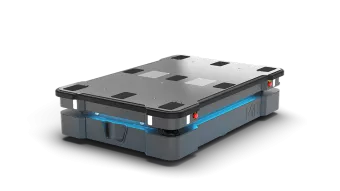

The PM800-MiR is a highly capable pallet mover designed to work with various Mobile Industrial Robots (MiR), including the MiR500, MiR600, MiR1000, and MiR1350. It measures 1344.2 x 904.2 x 165 mm and weighs 150 kg, with a maximum handling capacity of 1200 kg, depending on the AMR's load capacity. This device operates at a speed of 200 mm/sec, facilitating the efficient transport of EU and half-size pallets within industrial environments.

One of the standout features of the PM800-MiR is its integrated technology that enables wireless communication with external roller conveyors. This feature, combined with the Nord Modules Dock Target, allows for seamless docking and transfer of pallets. The pallet mover's design supports docking from both sides, enhancing its flexibility in operations. Additionally, it includes advanced technologies such as a PLC controller, servo technology, and an automatic mechanical stop-solution to ensure safe and precise handling of heavy payloads.

The PM800-MiR is particularly useful in optimizing logistics and production processes by automating the movement of pallets to production lines, packing stations, and other key areas. This reduces the need for manual handling, increases efficiency, and ensures a smooth workflow. The device's ability to provide high levels of operational feedback through stack-lights and the option for rubber-coated rollers further underscores its suitability for demanding industrial applications.

| Application |

|

| Industry |

|

| Speed | 0.02 m/s |

| Payload | 1200 kg |

| Product mass | 150 kg |

| Type of Technology |

|