Period

- 2021

Ranked Nr. 18 of 85 Robot Software

Smart3 machine vision software is developed based on the Vision SDK. Users can implement a vision project via simple graphical flow editing and configuration without any coding.

Specifications:

Image: Camera Setting, Image Acquisition, Image Import, Image Cache, Image Export, Auto Calibration, Light Calibration, Coordinate Transformation

Enhance: Preprocess, Filter, Tile Images, Image Operation, Threshold, Resize, Channel Extraction, Morphology, Brightness Contrast Gamma, Rotation, Mirror, LUT, Crop Image, Equalize Histogram

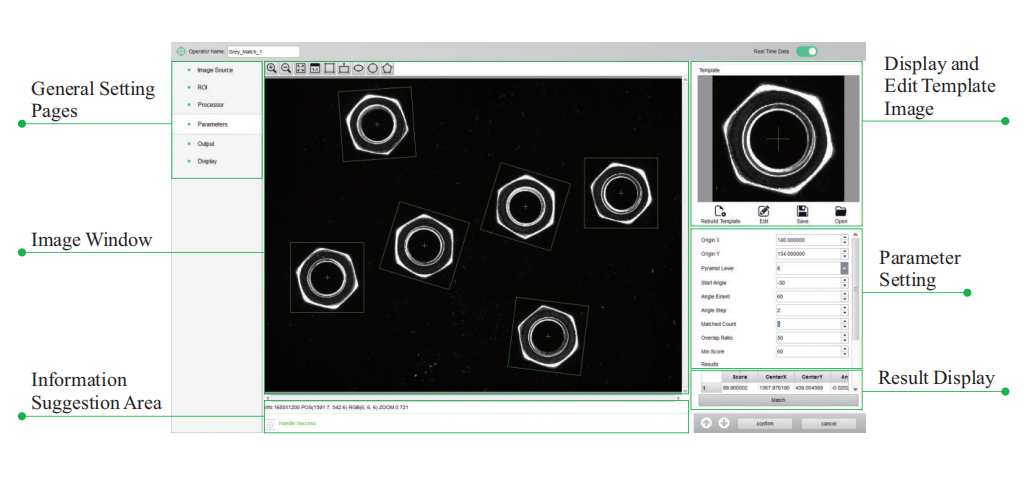

Location: Find Point, Find Line, Find Circle, Grey Match, Feature Match, Contour Match, ROI Creation, Hough Circles, Hough Lines, Corner Detection, Pick&Place

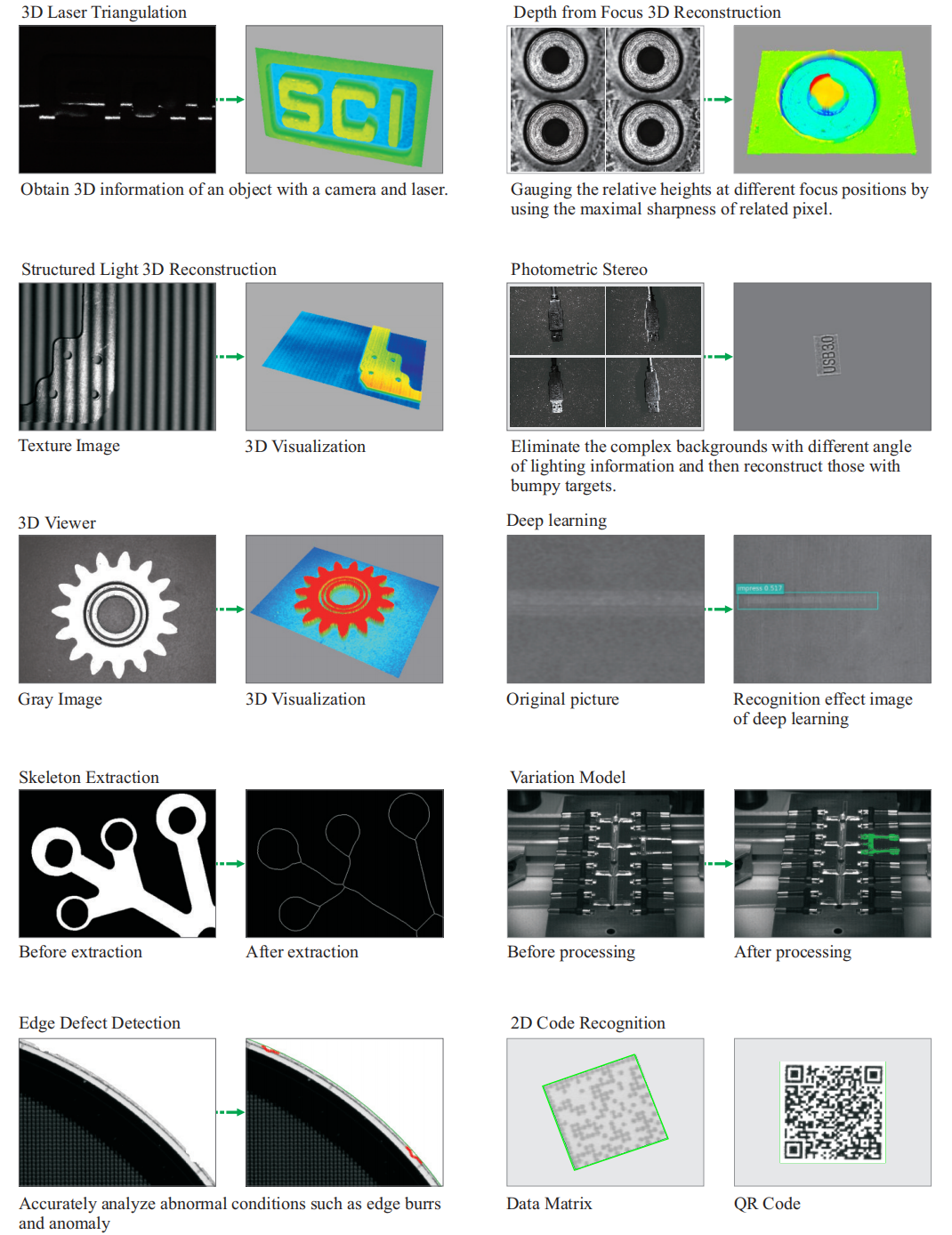

Measure Feature: Caliper, Pitch Measurement, Geometry Relationship, Auto Focus, Color Measurement, Intensity Measurement, 3D Laser triangulation, Focus 3D

Surface Inspection And Blob Analysis: Blob Analysis, Scratch Detection, Contours Extraction, Contours Processing, Variation Model, Profile Tolerance, Contour Contrast, Data Conversion, Edge Defect Detection

Recognition: OCR, Barcode Reading, 2D Code Reading, Classifier

Communication: TCP/IP, Serial Port, GPIO, Modbus, HID, Keyboard Event

Control: Logic Calculator, Array Converter, Script or, Variable Assignment, Overlay, Delay, Plugin Library Popup Dialog, Export to CSV, Variable Logs, Database Operator, Exit Program

Function:

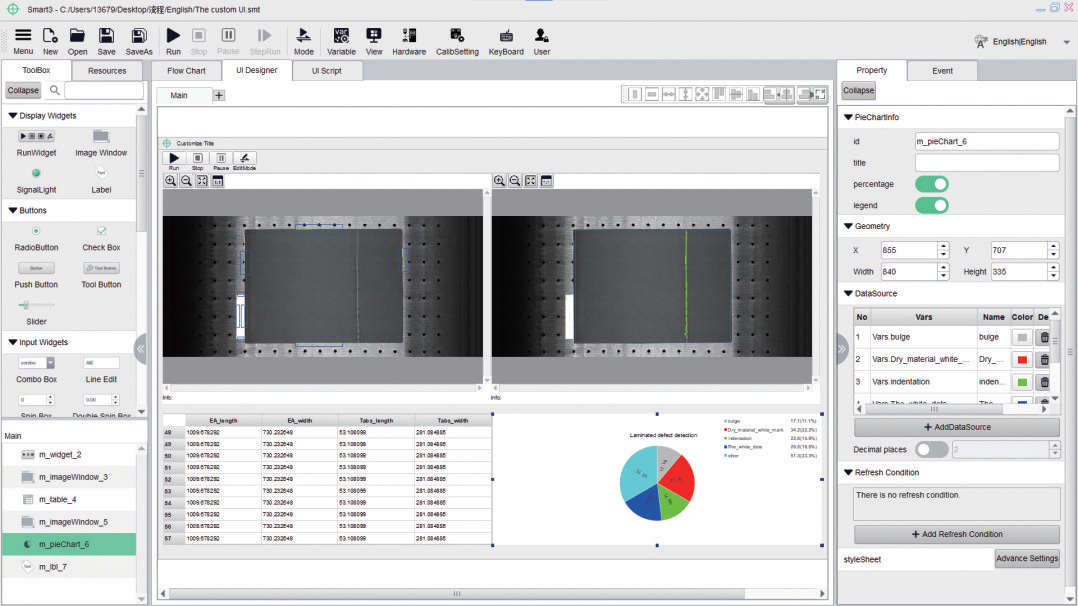

User Defined UI

UI layout is customizable via drag and drop to meet operator interface requirement. Definable UI can replicate previous operator UI environment thus reduces operator’s learning curve.

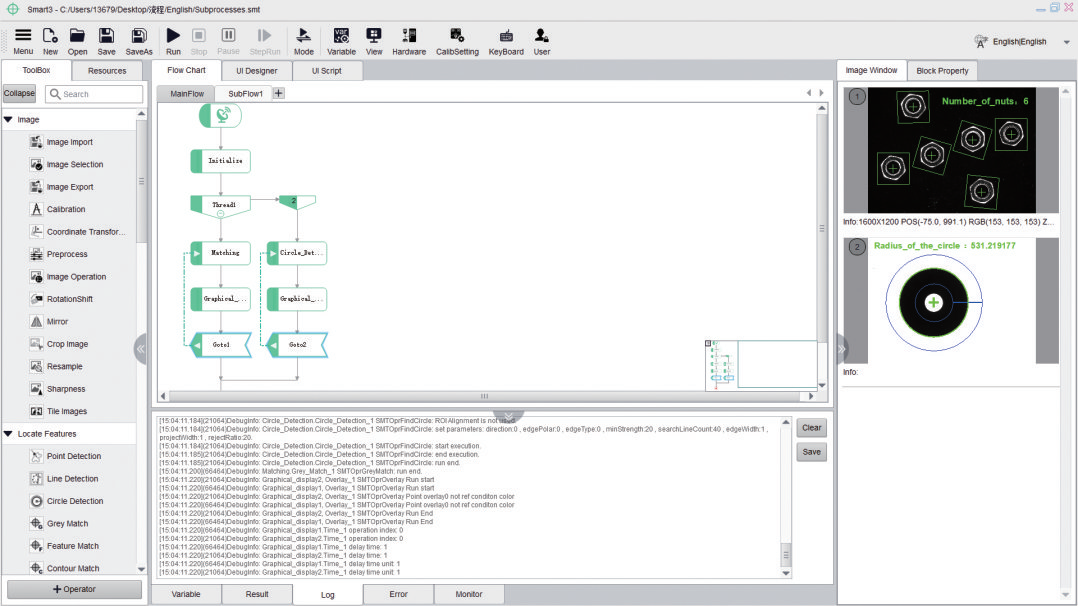

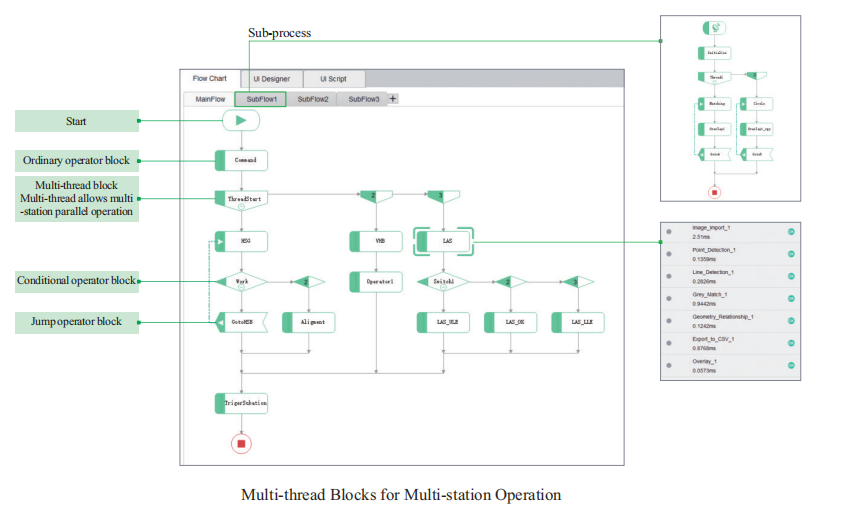

Subroutine Flow

Added subroutine flow to simplify main flow visual. Subroutine flow defines parallelism in a concise manner regardless if an event is triggered or running in background synchronously or asynchronously.

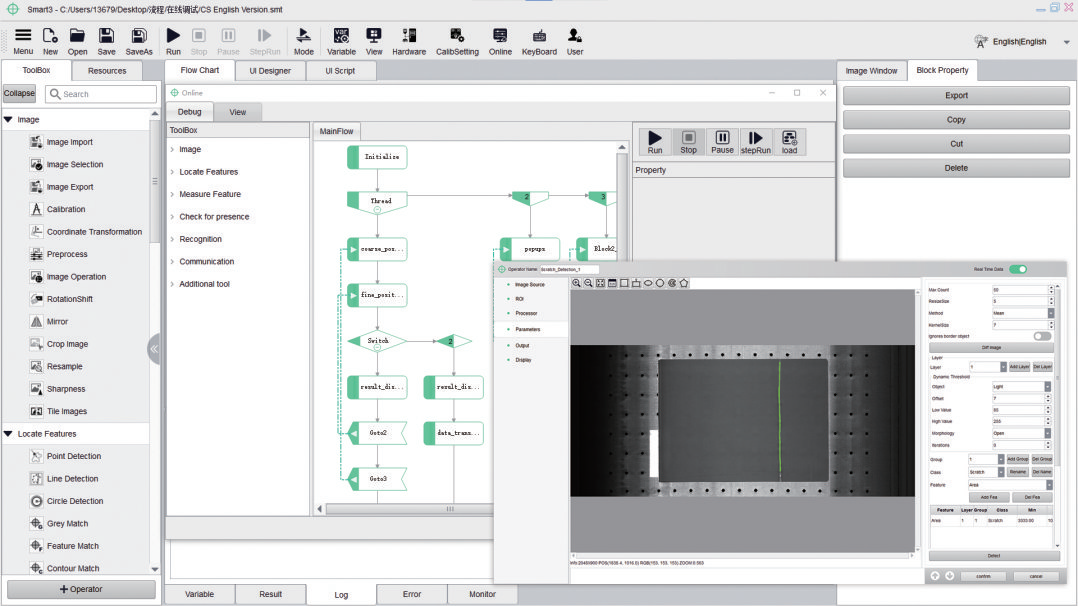

Online Debugging

Support online parameter adjustment, the tool parameters can be adjusted during operation, a better debugging method.

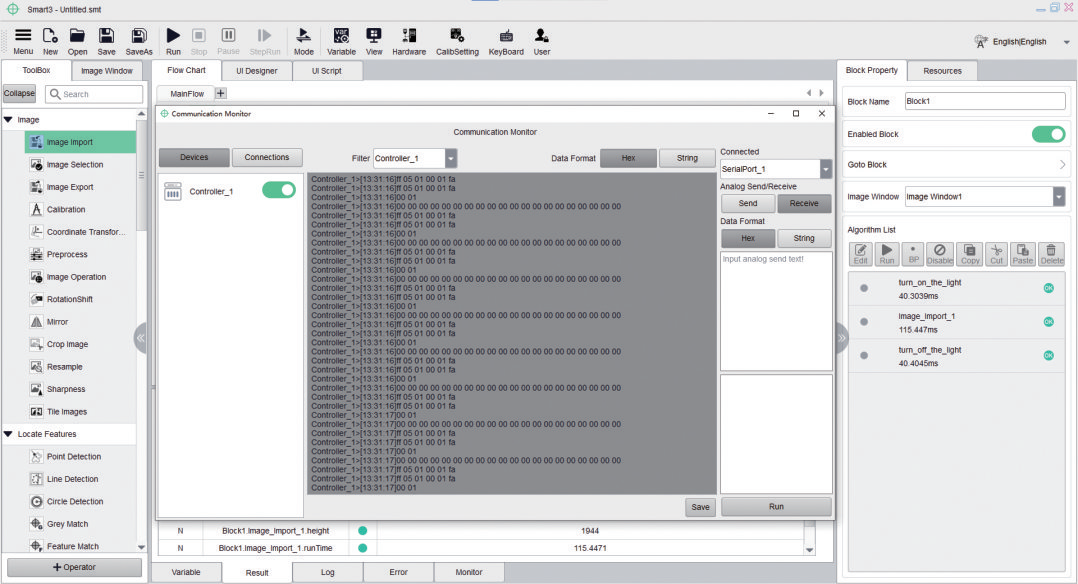

Communication Monitoring

Real time monitoring of communication sending and receiving data, when abnormalities occur, it can analyze and troubleshoot problems in time.

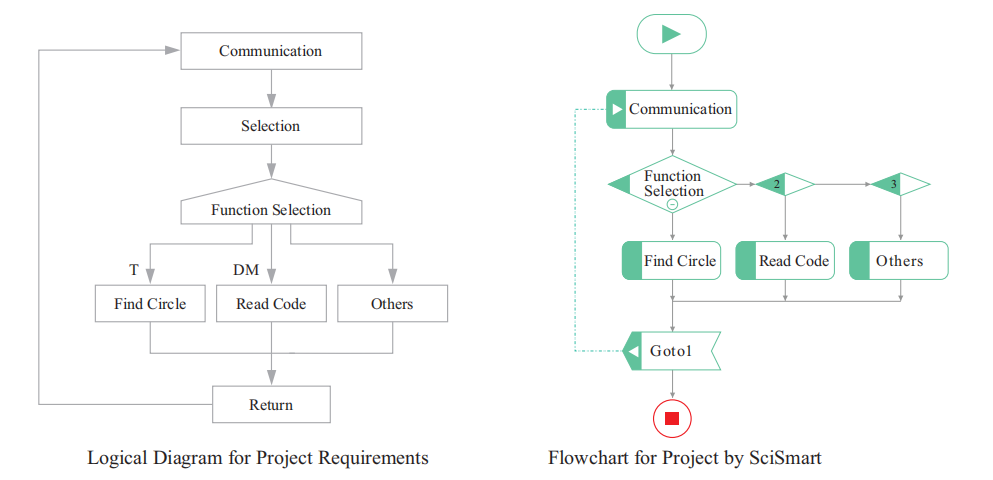

Graphical Programming

By taking circle detection and 2D code recognition tools as example.

Concise Flowchart

There are two types of basic elements in the flowchart, one is the operator block, and the other is the control operator block. After the process is established, it can jump to the sub-flow chart through conditional control combined with event triggering to complete the entire detection process.

Stable & Easy to Operate

Most tools provide a unified parameter setting interface and default parameters.

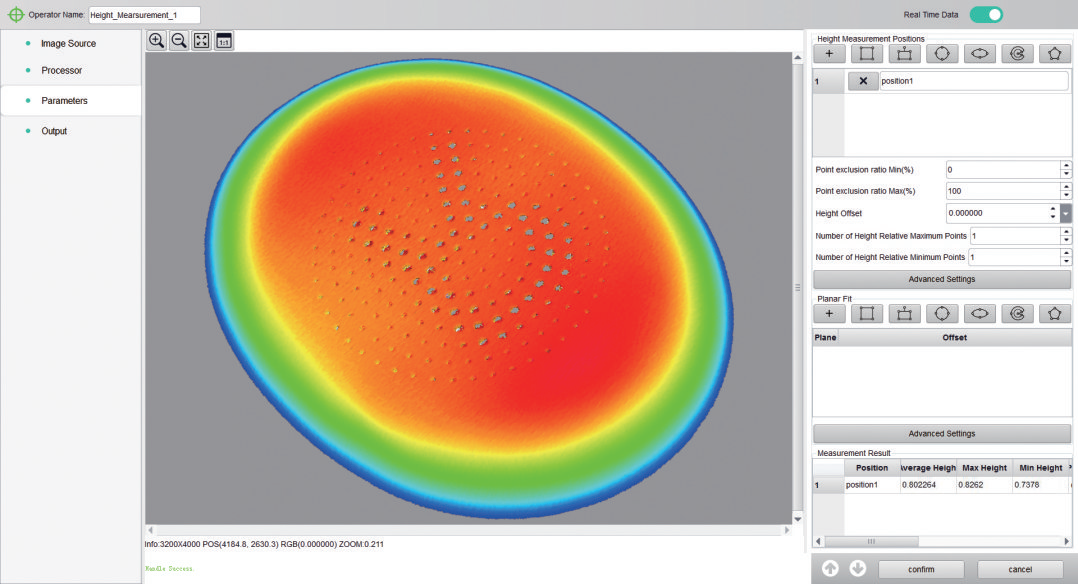

3D Height Measurement

Measure the real height between target area and datum plane by depth image. The precision is up to micrometer level.

Software Features

Measure the real height between target area and datum plane by depth image. The precision is up to micrometer level.

| Software type |

|