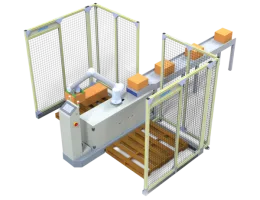

Peeters GoBot Palletise Solution Specifications

Ranked Nr. 47 of 61 Turnkey Robot Solutions

The cobot palletiser is the palletiser robot’s little brother. The cobot also automatically loads pallets with pre-packed products but is half the size of the larger version and easy to move around. We developed this cobot palletiser, named GoBot Palletise Solution, in-house.

COBOT PALLETISER IDEAL FOR SMES

Our GoBot Palletise Solution is the ideal (and often first) robot solution for small and medium-sized industrial companies that no longer want to manually stack goods coming off of the production line.

THE COBOT IS EASY TO HANDLE

(Pre)programming makes it easy for any employee to work with this cobot. No programming knowledge is required to set stacking patterns, for example. The cobot palletiser also stores each stacking pattern in its memory.

The cobot is equipped with motion sensors so people can work safely in its vicinity (changing pallets, for example, is not a problem)

Cobot Palletiser features:

- Product name:

- Application: Standard turnkey palletising cobot for light industrial palletising

- Capacity: up to 6 strokes per minute

- Maximum stacking height: 2 metres

- Voltage: 230 V

- Dimension: < 4 m2

- Cage: no

- Installation time: 1 day

- Force sensors: yes

- Change over time: minimum

- Maintenance: low

- Vision and line tracking: optional

- Energy consumption: low

- Delivery time: 4-6 weeks

- Programmed according to the ISO/TS-15066 standard

- Extra options:

> Malfunction data can be read out via Remote Support Router

> Lift unit for stacking up to 2 metres