Pickit 3D Assembly Alternatives & Competitors

Ranked Nr. 144 of 97 3D Vision Systems

Top 10 Assembly Alternatives

- Pickit 3D Bin Picking - Random Parts

- Pickit 3D Depalletizing Boxes or Bags

- Pickit 3D Surface Treatment & Dispensing

- Pickit 3D Bin Picking Sheet Metal

- Pickit 3D Bin Picking Billets

- SensoPart VISOR® Robotic - Vision sensor

- Automation Technology C6 Series

- Visio Nerf CIRRUS 3D CONVEYER

- Visio Nerf CIRRUS 150

- Visio Nerf CIRRUS 300

- Visio Nerf CIRRUS 1600

Pickit 3D Bin Picking - Random Parts

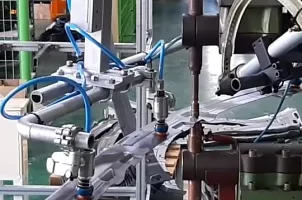

Have your robot pick parts from bulk and load your production line using a 3D vision system. A robot needs eyes to find the positions and orientation of parts on a tray, bin, or in a box.

How your machine tending process benefits from 3D vision automation:

1. Flexibly and cost-efficiently adjust your processes and set up new products quickly without major interventions by external service technicians

2. Cut costs by saving on downtime, maintenance and low value production tasks

3. Take a big step towards smart manufacturing with reliable 3D vision bin picking and machine tending

Pickit 3D Depalletizing Boxes or Bags

How much time is your workforce wasting on straining and tedious tasks?

Free your operators for value-added tasks and start depalletizing with 3D robot vision.

How your logistics process benefits from 3D vision automation:

1. Improve your depalletizing process with robotic precision and speed.

2. Cut costs by saving on low value manual labor and reducing downtime.

3. Free your labor force from tedious, straining and potentially injuring tasks.

4. Optimize ergonomics and use of warehouse or factory space.

Pickit 3D Surface Treatment & Dispensing

Are manual or mechanical interventions slowing down your production line?

Automate your sanding, sealing, deburring or any part processing with 3D robot vision.

How your process benefits from 3D robot vision:

1. Avoid unreliable product quality and inaccuracies caused by imprecise mechanical production techniques or human intervention.

2. Automate processes that used to be daunting to automate with robots.

3. Free your labor force from stressful, repetitive or complex process tasks.

4. Reduce your downtime by flexibly, rapidly and cost-efficiently switching to new processes, products and parts without major interventions.

Pickit 3D Bin Picking Sheet Metal

Losing time adjusting your stamping, bending or punching machines when changing products?

Time to make your processes more flexible, reliable and safe with 3D vision robot automation from Pickit3D

How your machine tending process benefits from 3D vision automation:

1. Eliminate time-consuming stacking and raw material preparation

2. Flexibly adjust your processes and set up new products quickly without major interventions

3. Take a step towards lights-out automation with reliable 3D vision bin picking and placing

4. Get rid of dangerous manual production tasks.

Pickit 3D Bin Picking Billets

Do you still rely on noisy and costly mechanical – or manual - billet feeding?

Time to bring your forge to the 21st century with 3D vision robot automation from Pickit3D!

How your forge benefits from 3D vision automation:

1. Avoid high maintenance costs of feeders

2. Use space better and reduce noise in the factory

3. Flexibly adjust or change billet types without major interventions

4. Reduce downtime with reliable and safe billet picking

5. Introduce smaller production runs cost-effectively

SensoPart VISOR® Robotic - Vision sensor

Color | MonochromeSensoPart VISOR® Robotic is a cutting-edge vision sensor designed for industrial automation applications such as pick-and-place, assembly, gluing, and screwing. Its standout feature is its seamless integration with robot controllers, streamlining the vision system integration process. The sensor offers precise calibration methods tailored to specific applications, ensuring accurate results and optimal performance in diverse automation tasks. The utilization of Target Mark technology enables fast and efficient 3D object poses, enhancing its capabilities further.

The VISOR® Robotic's installation is made hassle-free with its 3D grip point transformation feature and standardized interfaces, facilitating easy integration into existing systems. The sensor comes in different versions, including the Advanced version for common image-guided robotics applications and the Professional version with extended functionality like enhanced calibration methods and 3D localization capabilities.

One of the sensor's primary applications is reliable material feeding, accurately locating and gripping components without the need for mechanical alignment, leading to cost savings and improved efficiency. Additionally, it excels at detecting component poses in screw positioning applications, enhancing production quality and reducing mechanical effort. For mobile workstations, the VISOR® Robotic ensures precision and flexibility, enabling mobile robots to move accurately, establish mechanical connections with Target Mark 3D technology, and implement workstation safety zones, maximizing productivity and safety.

Automation Technology C6 Series

- World’s fastest 3D sensor in the combination of speed and resolution

- Advanced 3D technology (HDR-3D)

- Intelligent line detection algorithms with advanced filtering and validation for highly accurate scans

- Wide measuring range

- Available as 3D camera, 3D sensor and MCS module

- Industrial protection class IP67

- Service-friendly design

Optimization C6 Series Compared to C5 Series:

C6-3070 with on-sensor processing for world’s fastest 3D profiling based on AT’s own sensor technology

C6-4090 is 1.8 times faster compared to the C5-4090 with the same resolution

Unique new MultiPart feature: parallel output of up to nine different features (e.g. range, reflectance, scatter) at maximum profile speed with optimized pixel formats

Unique new feature MultiPeak: output of up to four different peaks for even more robust 3D data and for scanning transparent objects

Support of the latest 3D standard through GenICam 3.0

Visio Nerf CIRRUS 3D CONVEYER

cirrus3D conveyor allows a simplified, fast and flexible integration with your production lines. The cirrus3D conveyor is designed to integrate the core of your installation without specific development. This 3D scanner is used in a fixed position above a conveyor belt carrying parts, equipped or not with eyesberg3D image processing software (patented technology) for the implementation of vision / robotics applications of incomparable efficiency and of very high quality. These sensors are built for industrial use, cirrus3D conveyors are therefore less sensitive to the environment, dust and brightness variations to ensure unpararelled reliability and robustness of your installations(IP65).

Visio Nerf CIRRUS 150

Working distance 300mmcirrus3D is specifically designed to integrate the core of your installation without specific development.

Cirrus3D allows the implementation of applications with vision / robotics of incomparable efficiency and very high quality. Dedicated to industrial use, these sensors are not very sensitive to the environment, dust, dirt or the variations of brightness and this in order to guarantee an unmatched reliability and robustness of your installations (IP 65).

Visio Nerf CIRRUS 300

Working distance 450mmcirrus3D is specifically designed to integrate the core of your installation without specific development.

Cirrus3D allows the implementation of applications with vision / robotics of incomparable efficiency and very high quality. Dedicated to industrial use, these sensors are not very sensitive to the environment, dust, dirt or the variations of brightness and this in order to guarantee an unmatched reliability and robustness of your installations (IP 65).