Quicktron M150 Alternatives & Competitors

Ranked Nr. 103 of 183 Mobile Robots

Top 10 M150 Alternatives

- Robotnik RB-ROBOUT

- OMRON HD-1500

- MontrealRobot 100kg - 1500kg AGV

- Fetch Robotics Freight1500

- Synersight CMV Model

- Nord Modules NORD Conveyor 1000 V4 – OTTO 1500

- STÄUBLI PF100 omni

Robotnik RB-ROBOUT

AMR | Payload 1000kg | Product mass 350kgThe Robotnik RB-ROBOUT is an advanced autonomous mobile robot (AMR) engineered for heavy-load transport in indoor environments, specifically suited for industrial and logistics settings. With a robust payload capacity of up to 1,000 kg, it can move materials and goods efficiently within factories and warehouses. Its low-profile, steel-bodied design allows it to navigate under and lift trolleys or carry large loads directly on its platform, optimizing space use and enhancing transport flexibility in confined environments.

Equipped with omnidirectional kinematics and four high-powered drive wheels, the RB-ROBOUT achieves smooth, multidirectional movement, allowing it to navigate tight spaces and optimize routes. Its safety features, including dual 2D safety scanners and front and rear RGBD cameras, enable it to operate alongside human workers by detecting obstacles and autonomously rerouting as needed. This AMR supports various localization systems like SLAM for dynamic mapping and magnetic guidance for applications requiring high-precision positioning.

The RB-ROBOUT’s modular architecture, based on the ROS framework, allows for easy integration with additional components, such as conveyor belts, roller paths, and load elevators. Its autonomy of up to 10 hours, combined with optional AI and vision packages, makes it highly adaptable for diverse industrial applications, including loading/unloading, material transport, and specialized logistics tasks. This flexibility in configuration and customization makes the RB-ROBOUT an effective solution for automating repetitive heavy-load transport tasks in complex, high-demand environments.

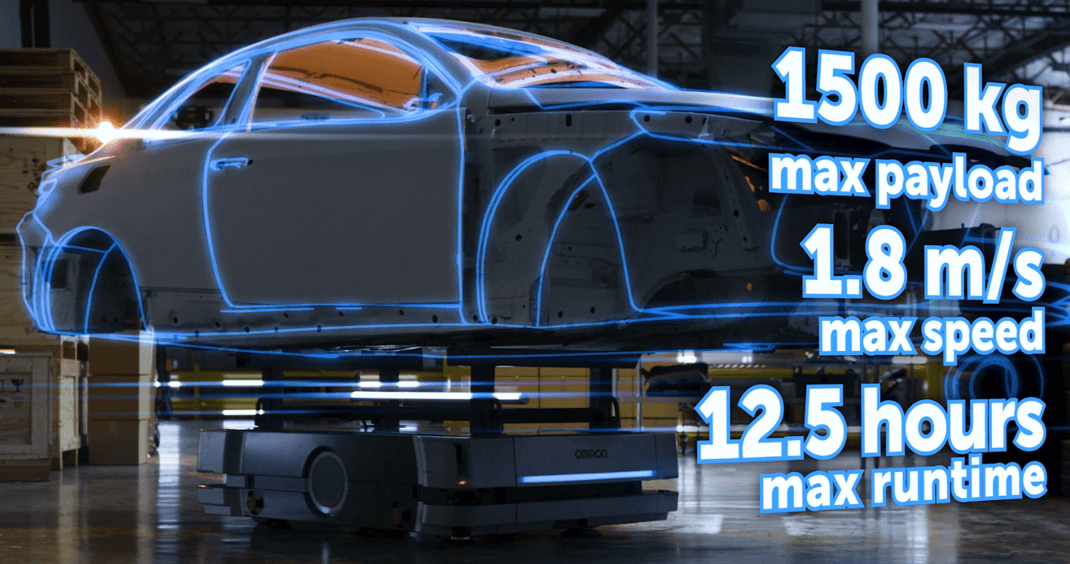

OMRON HD-1500

AMR | Payload 1500kgThe HD-1500 boasts a payload capacity of 1,500 kg and allows customers to lead and transport the heaviest of objects. Designed for industrial manufacturing, reduce the need for forklifts and do more with less equipment.

The HD-1500 is an advanced autonomous mobile robot specifically designed to transport heavy payloads up to 1500 kilograms. The HD-1500 also represents innovations in mobile robotics. Its new architecture features lasers that provide 360-degree safety coverage, as well as an onboard programmable logic controller, or PLC, to easily interface with custom attachments. Heavier payloads, built-in controller, improved sensors, route planning and object avoidance, the OMRON HD-1500 autonomous mobile robot offers the most advanced performance and safety.

Features:

Maximum payload is 1500 kg

The 1,500 Kg payload Omron HD-1500 mobile robot handles the performance of simple transport, delivery, and routing operations so your employees can perform higher-value jobs.

Automate new jobs

The higher payload capacity allows customers to automate new tasks that were not previously possible, such as the transport of pallet-size loads, engine blocks, and other heavy goods and equipment. The HD-1500 can also automate tasks that are traditionally completed with forklifts, reducing the risk of injury.

The most customizable solution for your factory

Omron allows customers more options in terms of customizing a mobile solution, which now includes incorporating the HD-1500, giving customers more choice in developing a customized automated solution.

The HD-1500 can be used to create a solution that best meets the needs of every manufacturer.The HD-1500 also takes advantage of Omron’s ability to customize the fleet with accessories that improve performance, such as HAPS and LiDAR. With the industry-leading Fleet Manager, Omron mobile fleets can be more diverse and still be controlled through the same system, allowing for a completely automated solution. Designed to meet the industry’s latest requirements, our mobile robots interact with people to promote a collaborative, safe working environment.

MontrealRobot 100kg - 1500kg AGV

Payload 1500kg | Product mass 300-1500 kgMontrealRobot Moving solution includes 300kg, 600kg, 1000kg, 1500kg AGVs models equipped with lifting attachments. All robots provide standard lifting module includes Lidar and QR code navigation that enables AGVs to follows virtual lines in complex environments. Optional to customize the module for different height, dock mechanisms, and payloads.

Fetch Robotics Freight1500

AMR | Payload 1500kg | Product mass 469kgThe Fetch Robotics Freight1500 is a remarkable industrial Autonomous Mobile Robot that enables on-demand pallet transport with no infrastructure changes required. This unique feature eliminates the need for any wires, magnets, tape, or QR labels to be installed in your facility. The automated pallet mover can be deployed within days and can be scaled up as your operations grow. With the Freight1500, pallet pick and putaway are significantly improved by reducing manned travel, reducing forklift dependency, traffic, and incidents.

The Freight1500 is designed to safely transport large and heavy payloads autonomously throughout your facility, making it the new workhorse of the warehouse. This feature frees up forklift operators' valuable time, which can be redirected to higher value tasks. Automating pallet transport reduces traffic and incidents, making the warehouse environment less congested and safer. The Freight1500 can accommodate a standard North American pallet size of 40″x48″ and has a 1500kg payload capacity. Its proprietary design and built-in sensor technology provide the smoothest movement, resulting in class-leading safety and speeds.

The Freight1500 is designed to automate repetitive case movement and pallet transport workflows in your facility. With On-Demand Automation, you can take control of your automation by instantly modifying workflows using the powerful cloud-based software. This unique feature allows you to address dynamic business environments and just-in-time demand. The Freight1500 has high duty cycles enabled by fast charge capability, which ensures that your operations can continue without any downtime.

Synersight CMV Model

Intended for the transport of heavy loads, offering the option of working outdoors and manual handling.

This model allows the dragging transport of heavy loads through three models, based on their capacity: 5.000, 8.000 and 10.000 Kg., all of them in internal and external logistics. They are very efficient machines, since they allow large amounts of product to be moved and the load to be hooked or unhooked automatically, thanks to the type of hook they incorporate.

Despite their robustness, they are very safe machines as they are designed with the most modern security technologies on the market.

Model:

- CMV8000

- CMV10000

Nord Modules NORD Conveyor 1000 V4 – OTTO 1500

Product mass 250kgThe NORD Conveyor 1000 V4 – OTTO 1500 is designed to enhance the operational capabilities of the OTTO 1500 autonomous mobile robot by enabling it to receive and deliver pallets efficiently. With dimensions of 1745 x 1205 x 165 mm, this conveyor can handle a maximum load of 1650 kg, making it suitable for transporting heavy payloads to production lines or packing stations. The conveyor's transport area measures 1623 x 1138 mm, providing ample space for large pallets, while its speed of 200 mm/sec ensures swift and efficient movement.

A key feature of the NORD Conveyor 1000 is its integrated technology that allows wireless communication with external roller conveyors. This capability, combined with the OTTO Standard Dock Target, enables the conveyor to dock seamlessly and autonomously transfer pallets. The system's design includes a center distance of 95.8 mm between rollers and a robust construction weighing 250 kg, ensuring durability and reliability in demanding industrial environments.

The NORD Conveyor 1000 is highly versatile and user-friendly, offering docking from both sides (run-through) and a high level of feedback through its stack-light system. It is equipped with PLC controller and servo technology for precise operation, and an optional rubber coating of the rollers can be added for enhanced grip. This solution is ideal for optimizing logistics and production processes, particularly in industries requiring the transport of US-sized pallets and other large items.

STÄUBLI PF100 omni

Payload 7000kg | Product mass 1000kgThe STÄUBLI PF100 omni is a versatile autonomous mobile robot designed for various industrial applications. Its standout feature is its omni-directional wheel system, allowing it to move in any direction without turning. This unique mobility enables precise and efficient material handling in tight spaces and complex layouts, making it suitable for industries where space optimization is crucial.

With a payload capacity of up to 100 kg and a top speed of 2 m/s, the PF100 omni is a robust and capable solution for tasks such as material transport, palletizing, and assembly. It operates seamlessly in diverse environments, thanks to its compatibility with industry-standard software systems and protocols, making integration into existing automation processes straightforward. Additionally, it offers a high degree of safety with advanced collision avoidance technology and user-friendly programming interfaces.

One of its lesser-known but significant specifications is its adaptability to extreme temperatures. The PF100 omni can operate in environments with temperatures ranging from -20°C to +45°C, making it suitable for both cold storage and high-temperature manufacturing settings. This versatility, combined with its omni-directional mobility and high payload capacity, positions the PF100 omni as a valuable asset in various industrial automation scenarios, optimizing productivity and adaptability in challenging conditions.