REECO CP1200 Case Packer Specifications

Ranked Nr. 46 of 61 Turnkey Robot Solutions

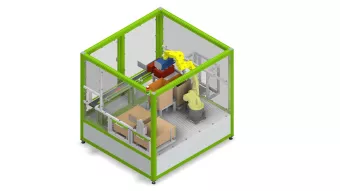

CP1200 CASE PACKER MACHINE – AUTOMATIC CASE PACKAGING

Developed by Reeco, the CP1200 Case Packer is a versatile case packing system, perfect for packing boxes and trays in end-of-line packing processes.

From single and dual arm cells, to single and multi-pick configurations, the CP1200 can be modified to meet different production throughputs and packing patterns as required. Its compact design demands reduced floor space, making it an attractive solution to producers of all sizes.

High Throughput – The CP1200 is capable of achieving upwards of 1200 cycles per hour.

High Payload – The Omron TM14 Robots are suitable for handling payloads of up to 14KG each.

Versatile Solution – The CP1200 is suited to both box and tray packing.

Quick Integration – Easily integrated with upstream and downstream systems.

The CP1200 Case Packer

The CP1200 Case Packer utilises Omron TM14 Collaborative Robots which provide a reach of 1100mm and a payload of 14kg. With dual and single arm models, its inverted design allows for a quicker pick and a shorter travel time, improving product throughput and reducing the required footprint.

We are able to provide custom tooling to suit different products, accommodating the packing of bottles, cans, bags, boxes, trays, food items, tubs, wrapped product, pots & pouches.