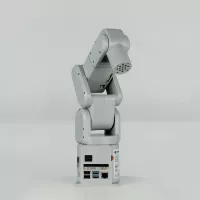

RETHINK ROBOTICS BAXTER [permanently unavailable] Specifications

Ranked Nr. 89 of 207 Cobots

Baxter is a collaborative robot, also known as a cobot, designed and developed by Rethink Robotics. One of the standout features of Baxter is its ability to work safely alongside human operators, without requiring traditional safety barriers or cages. This makes it an ideal option for industrial settings where human-robot collaboration is necessary, such as manufacturing and assembly lines.

One of the most unique aspects of Baxter is its adaptive behavior. Rather than relying on pre-programmed movements, Baxter is able to adapt to changes in its environment and perform a variety of tasks using its advanced sensing and vision capabilities. This makes it incredibly versatile and able to perform a wide range of tasks, from picking and placing objects to performing quality control inspections.

Baxter is also designed with ease of use in mind. Its user-friendly interface and intuitive programming system make it easy for operators to program and teach Baxter new tasks without requiring specialized technical expertise. This means that even operators with limited programming experience can quickly learn to use Baxter and integrate it into their workflow.

Another standout feature of Baxter is its durability and reliability. It is designed to operate in harsh industrial environments and can withstand extreme temperatures and humidity levels. It also has a high payload capacity, allowing it to handle heavy objects and perform tasks that other cobots may not be able to handle.

In terms of specialized specifications, Baxter is compatible with a variety of software systems, including ROS (Robot Operating System) and Python. This makes it easy for users to customize and program Baxter to meet their specific needs and integrate it into their existing systems. Baxter is also designed to be easily upgraded and maintained, ensuring that it remains a valuable tool for industrial automation for years to come.

Overall, Baxter is a highly advanced and versatile cobot that is well-suited for a wide range of industrial automation applications. Its unique features, ease of use, and compatibility with specialized software systems make it a popular choice for manufacturers and other industrial operators looking to improve efficiency, safety, and productivity in their operations.

| Application |

|

| Industry |

|

| Payload | 2.2 kg |

| Reach | 1210 mm |

| Repeatability | 3 mm |

| Number of Axes | |

| Robot mass | 75 kg |