SAFELOG AGV L1 Alternatives & Competitors

Ranked Nr. 26 of 183 Mobile Robots

Top 10 AGV L1 Alternatives

- SAFELOG AGV M4

- KUMATECH Lifting Jim

- Wellwit Robotics W500SL Under Ride Lifting AGV

- Neobotix MPO-700

- SAFELOG AGV S3

- IBG Automation FC Load

- Neobotix MPO-500

- Kivnon K41 Omnidirectional

- Quicktron M150

- GESSbot GB350

- OMRON HD-1500

SAFELOG AGV M4

Product mass 235kgThe SAFELOG AGV M4 transport robot, an evolution of the AGV M3, stands out for its diverse applications. With its reduced height of 220 mm (a 15 percent reduction), it effortlessly navigates beneath a wide range of trailers and trolleys available in the market.

Featuring an innovative system of lifting bolts and snap latches, the AGV M4 boasts automatic coupling and uncoupling capabilities, further augmented by an RFID reader for material supply trolley identification. With a substantial towing capacity of 1,500 kg, the robot can efficiently transport heavy loads. In its standard configuration, the AGV M4 handles top loads of up to 200 kg. The robot's robust steel chassis is rated IP54, offering protection against dust and water splashes.

Powered by a newly developed brushless DC motor, the AGV M4 achieves higher starting torque, allowing it to reach speeds ranging from 0.02 m/s to 1.6 m/s. Leveraging intelligent, agent-based control, the robot communicates seamlessly with other transport robots and peripheral systems. Notably, its swarm intelligence capabilities eliminate the need for a higher-level control center, while interfaces for control center connections, including VDA 5050, are readily available, enhancing its adaptability in industrial automation workflows.

KUMATECH Lifting Jim

AGV | Payload 1500kg | Product mass 1200kgTo built an AGV which is able to lift 3 meters high and is still compact we developed Lifting Jim. Compared to Forklift Joe this AGV has 2 legs under the pallet which take care for the stability.

With those legs it`s not necessary to add additional weight at the back like the counterweight Forklift Joe, therefor we are able to built much more compact.

Lifting Jim uses the same navigation platform as his brothers with same advantages.

Lifting till 2m

Compact

Max. 1500kg

Completely designed and built in-house

Navigation on floor structure, no adjustments to the building needed!

Remote Access (connected vehicles)

Wellwit Robotics W500SL Under Ride Lifting AGV

AGV | Payload 500kg | Product mass 220kgThe Wellwit Robotics W500SL Under Ride Lifting AGV is a highly advanced autonomous guided vehicle designed for material handling applications in manufacturing and logistics industries. This AGV features the latest LiDAR SLAM navigation technology, which enables the vehicle to navigate and operate autonomously in complex environments. This technology uses lasers to map and create a 3D image of the AGV's surroundings, allowing it to avoid obstacles and navigate through tight spaces with ease. The LiDAR SLAM navigation system also allows for real-time localization and mapping, ensuring the AGV can quickly adapt to changes in its environment.

One of the key features of the Wellwit Robotics W500SL Under Ride Lifting AGV is its impressive 500 kg payload capacity. This makes it an ideal solution for material handling tasks that require heavy lifting and transport, such as moving large crates or pallets of goods. The AGV is equipped with a high-strength lift mechanism that can easily handle heavy loads, and its compact size and maneuverability make it ideal for use in tight spaces such as factory floors or warehouses.

In addition to its impressive payload capacity, the Wellwit Robotics W500SL Under Ride Lifting AGV also offers a high level of safety and reliability. The AGV is designed with multiple safety features, including a laser safety scanner that ensures the AGV can detect and avoid obstacles in its path. The AGV also features a robust collision avoidance system that can detect and respond to potential collisions, ensuring that the AGV can safely navigate around other vehicles or objects in its environment.

Overall, the Wellwit Robotics W500SL Under Ride Lifting AGV is an advanced and highly capable autonomous guided vehicle that is ideal for material handling applications in manufacturing and logistics industries. Its LiDAR SLAM navigation technology and 500 kg payload capacity make it a valuable asset for any business looking to improve their efficiency and productivity. With its advanced safety features and reliability, this AGV is a powerful tool for streamlining operations and reducing costs.

Neobotix MPO-700

AGV | Payload 400kg | Product mass 120kgThe omnidirectional MPO-700 is the ideal basis for high-end service robots. Its four Omni-Drive-Modules enable it to make smooth journeys in all directions. In addition it combines the advantages of classic wheels with the surface mobility otherwise only offered by Mecanum wheels.

The MPO-700's Omni-Drive-Mmodules offer important advantages compared to other omnidirectional drive systems, such as the MPO-500's Mecanum wheels.

The modules are also controlled by ROS.

SAFELOG AGV S3

Product mass 150kgThe SAFELOG AGV S3, succeeding the AGV S2, offers compact agility and diverse applications in industrial automation. Its compact dimensions enable a tight turning radius of less than 90 cm, making it ideal for maneuvering in confined spaces. Standing at a height of 220 mm, this mobile transport robot can easily navigate beneath standard trolleys and trailers, attaching them using snap latches. The S3's towing capacity reaches 500 kg, facilitated by an automatic electric lifting bolt for efficient load handling.

For transporting top loads, the AGV S3 accommodates up to 150 kg through adaptable structures featuring loading and unloading technology. A laser scanner positioned for travel direction maintains safety by defining warning and safety zones, ensuring obstacle detection and prompting appropriate actions. Communication among AGVs and peripheral systems occurs via WLAN or mobile phone networks. Utilizing the agent-based control software, IntelliAgent, the AGV models demonstrate swarm intelligence, obviating the need for a centralized control center and enhancing their autonomous functionality.

IBG Automation FC Load

AGV | Payload 1000kg | Product mass 450kgAutonomous forklift AGV for picking up and transporting Euro pallets or pallet cage.

Neobotix MPO-500

AGV | Payload 80kg | Product mass 80kgThe MPO-500 mobile robot has Mecanum wheels that give it exceptional maneuverability and the ability to move smoothly in any direction.

This allows the omnidirectional robot not only to navigate agily through narrow and twisty environments, but also opens up completely new working possibilities. Robot arms can be quickly moved to new positions, components can be freely positioned and measuring systems can be exactly positioned. Here the user also benefits from the freedom in development by ROS.

Kivnon K41 Omnidirectional

The Kivnon K41 Omnidirectional AGV/AMR is a unique solution for automating the transport of medium loads in highly complex processes. Its standout feature is its omnidirectional mobility, which allows it to maneuver in any direction with ease. Unlike other AGVs/AMRs, the K41 can perform maneuvers that were previously impossible, making it highly versatile in tight spaces and intricate work environments.

With a load capacity of up to 800kg, the K41 is capable of handling substantial loads. It offers precise navigation, ensuring accurate stops with full accuracy. The AGV/AMR is equipped with mapping navigation, allowing it to efficiently move throughout the facility. Additionally, it can be adapted to connect with fleet management systems, including those based on VDA 5050, for seamless integration into existing operations.

Safety is a top priority for the K41. It features 360º safety with laser scanners, ensuring obstacle detection and collision avoidance. The AGV/AMR also incorporates a safety PLC and LED signaling to enhance operational safety. On each front side, there is a status, error, and circuit control touch display, providing real-time information about its operation.

Measuring 1620mm in length, 850mm in width, and 285mm in height, the K41 offers a compact and space-efficient design. It operates in a lifting transport type, accommodating different load requirements. With a maximum speed of 1 m/s, it delivers efficient and timely transport. The K41 is powered by a lithium battery, supporting online charging in an integrated circuit for continuous operation.

The K41's versatility extends beyond load transport. It features a coupling system that can adapt to various trolleys, allowing for seamless integration with existing equipment. Moreover, it can serve as a workbench, further enhancing its utility in industrial settings.

With its exceptional maneuverability, high load capacity, and adaptability, the Kivnon K41 Omnidirectional AGV/AMR revolutionizes material transport in complex industrial automation processes.

Quicktron M150

AMR | Payload 1500kg | Product mass 223kgMaterial handling robot designed to move loads up to 1500kg, replacing traditional transport solutions like conveyor belts.

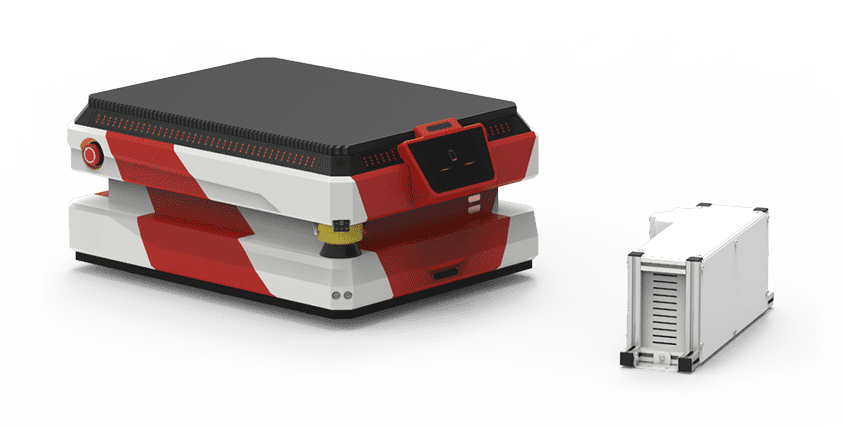

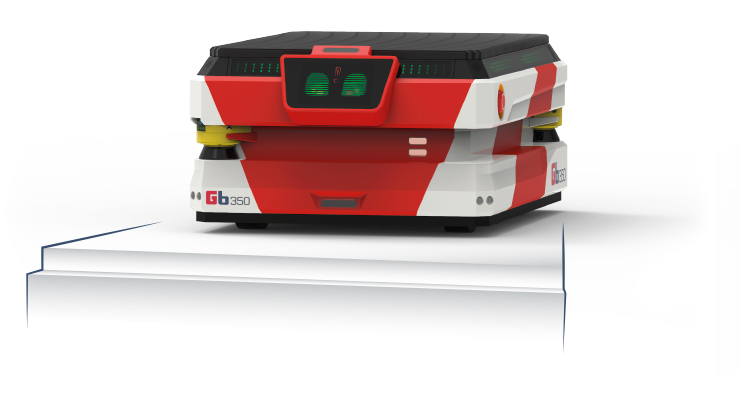

GESSbot GB350

AGV | Payload 350kg | Product mass 150kgThe Gb350 is an automatically guided vehicle (AGV) for quick and cost-efficient automation of your internal transport processes. The Gb350 has a payload of 350kg.

No expensive extras and auxiliary systems, such as magnetic tracks, induction loops or additional safety systems are required. The AGV easily integrates into your existing production and logistics structures.

Autonomous movement

The robot moves autonomously within your company. Thanks to the fusion of various sensor systems, the Gb350 maintains an overview of everything within a radius of 20 m.

Using the Social Navigation System (SNS), it reacts to dynamic changes and always choses the optimum route. People and machines work in perfect harmony thanks to this collaborative behaviour.

GESSbot Charge System

The charging process is fully automated

Fall protection thanks to step and cavity recognition

Overload-proof and with integrated scale

Great audio-visual features

Thanks to the GESSMANN Blackpanel System and an integrated sound module, we underline the actions and movements of the robot visually and acoustically. The latest energy-saving LED technology is used to do this.

Easy to operate

User-friendly, configurable interface

Structures with industry interfaces

Standard structures and customer-specific solutions can be provided. Those are connected directly to the Gb350 and thus form a unit.