Scape Technologies CNC Machine Tending Solution Pricing & Product Details

Ranked Nr. 25 of 61 Turnkey Robot Solutions

CNC Machine Tending Solution Pricing

Choose your model

CNC Machine Tending Solution Overview

What is CNC Machine Tending Solution?

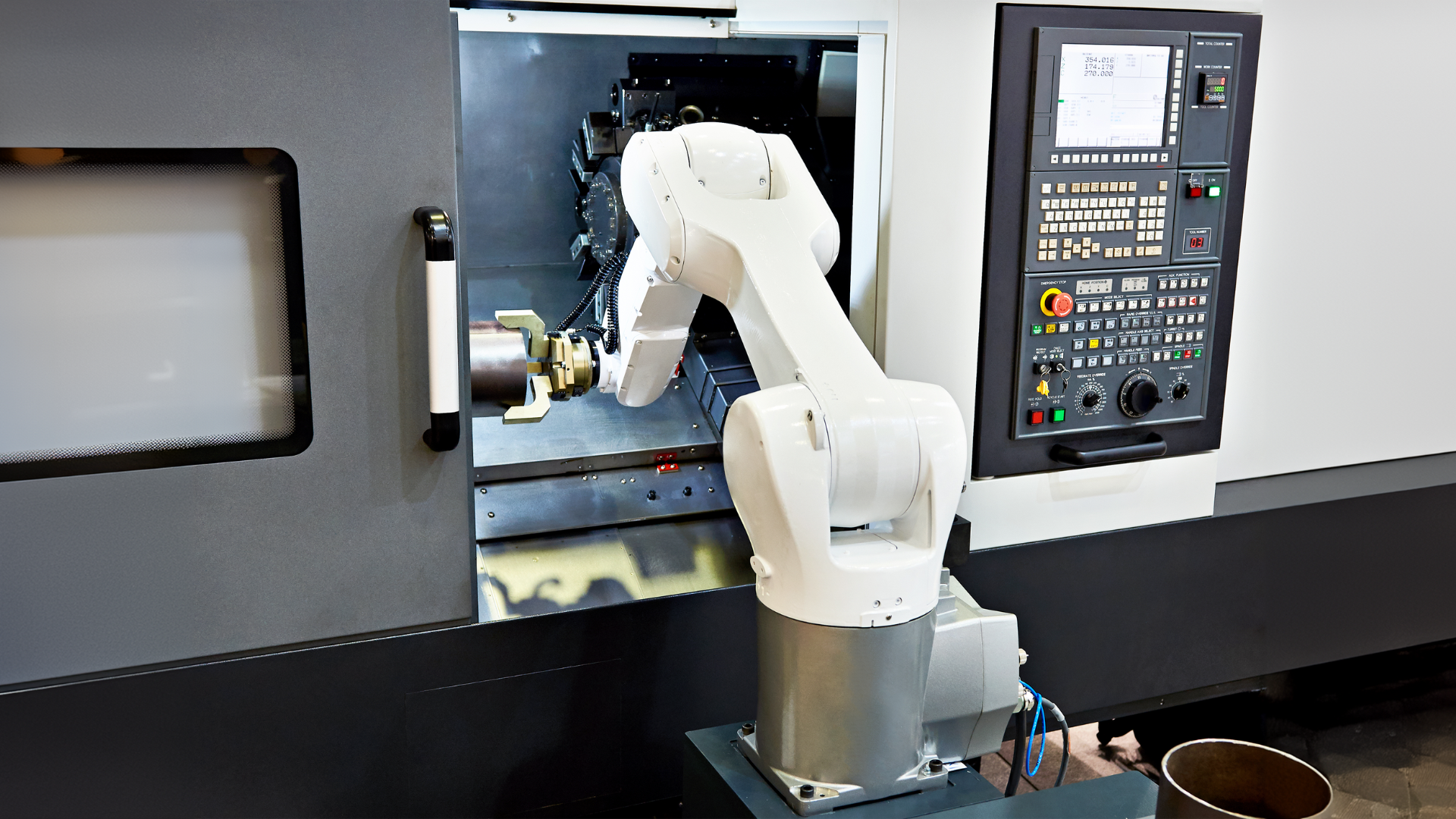

SCAPE CNC Machine Tending Solution is a standardized, cell designed for loading and unloading of CNC machinery. This solution consists of standard components, both hardware and software, that seamlessly integrate to create a complete, user-friendly, and reliable system designed to maximize machine utilization.

Key Features:

1. Free Proof of Concept: A cost-effective solution with no payments required until the Factory Acceptance Test.

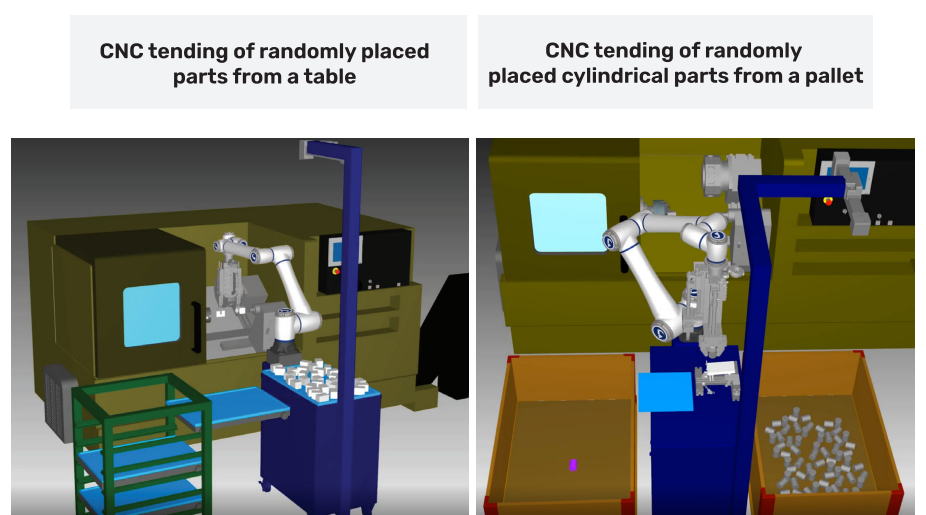

2. Enhanced Productivity: The use of advanced 3D vision technology enables the handling of randomly placed parts, eliminating the need for pre-organizing them in a structured manner and maximizing machine utilization.

3. Enhanced Productivity: Advanced 3D vision technology allows for the handling of randomly placed parts, eliminating the need for pre-organizing them in a structured manner and maximizing machine utilization.

4. Cost-Effectiveness: Payback periods as short as 12 months, making it a financially viable solution for enhancing production efficiency.

5. User-Friendly Interface: Features intuitive, no-code software that eliminates the need for robot programming and operation, enabling operators to manage multiple machines efficiently.

6. Rapid Implementation: From concept to full production in just 3 months.

7. Quick Setup: Ready for production within 30 minutes. Reconfiguration for new components can be accomplished in 5-10 minutes, allowing operators to independently program and set up for new tasks.

What applications is CNC Machine Tending Solution product best for?

- Automotive Industry: The SCAPE Robotic CNC Tending Solution enhances automotive manufacturing by automating the loading and unloading of unstructured parts such as engine blocks, transmission components, and brake discs. Its precision handling improves machining efficiency and ensures consistent production quality.

- Aerospace Industry: The SCAPE Robotic CNC Tending Solution optimizes the machining of complex aerospace components such as turbine blades, fuselage fittings, and structural brackets. Its ability to manage parts of varying shapes and sizes enhances the production of high-precision components required in aerospace manufacturing.

- Metal Fabrication: The SCAPE Robotic CNC Tending Solution streamlines operations in metal fabrication by automating the handling of raw metal parts such as sheets, rods, and castings into CNC machines. This increases throughput and reduces manual labor, ensuring precise machining of structural components.

- Medical Device Manufacturing: The SCAPE Robotic CNC Tending Solution is ideal for producing medical implants and surgical instruments by accurately loading unstructured parts into CNC machines. Its precision and repeatability ensure compliance with stringent regulatory standards in medical manufacturing.

- Tool and Die Industry: The SCAPE Robotic CNC Tending Solution improves the efficiency of tool and die manufacturing by automating the machining of molds, dies, and jigs. Its ability to handle complex geometries and unstructured parts ensures high-quality, repeatable production in tool-making processes.

- Electronics Industry: The SCAPE Robotic CNC Tending Solution automates the precise machining of electronic enclosures, heat sinks, and intricate metal components used in consumer electronics. Its automated handling increases production speed and reduces the risk of human error.

- Heavy Equipment Manufacturing: The SCAPE Robotic CNC Tending Solution supports the production of large, heavy-duty parts such as hydraulic components, construction machine fittings, and agricultural equipment parts. Its robust handling capabilities enable efficient processing of oversized and irregular parts.